O2 Sensor Wrench: The Right Tool for Fast Sensor Replacement

An o2 sensor wrench is a specialized tool designed to remove and install oxygen sensors in vehicles. These sensors monitor exhaust gases and help engines run efficiently. Over time, they wear out or fail, requiring replacement.

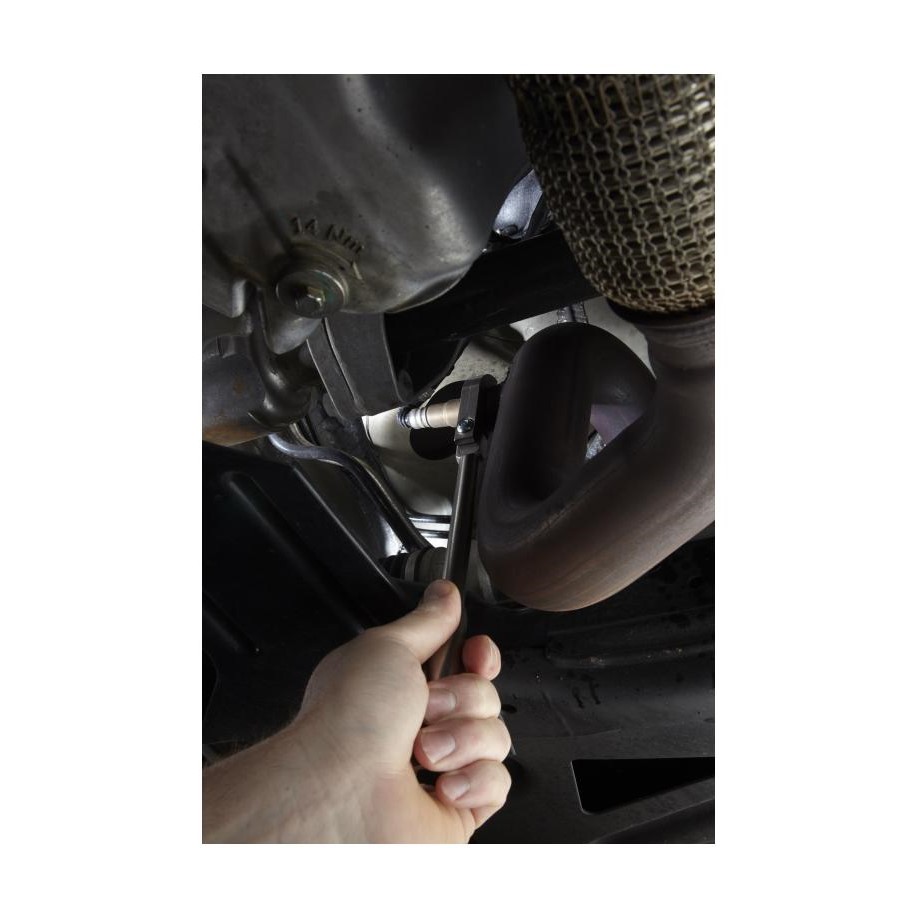

Because oxygen sensors are often located in tight, hard-to-reach spaces, standard wrenches rarely work well. That’s where an o2 sensor wrench becomes essential. It offers better grip, clearance, and control. Whether you’re a DIY mechanic or professional technician, using the right tool makes the job faster and safer.

What is an O2 Sensor Wrench?

What is an O2 Sensor Wrench?

An O2 sensor wrench is a specialized tool designed for removing and installing oxygen sensors. Oxygen sensors are crucial in determining the air-to-fuel ratio in vehicle engines. These sensors are usually located in hard-to-reach areas, such as on exhaust systems. Therefore, traditional wrenches may not work effectively for this purpose.

The O2 sensor wrench has unique features that make handling these sensors easier. It typically has a slot or cutout to fit around the sensor’s wiring. This ensures the wire remains untouched while providing a secure grip on the sensor itself. Some models come with flexible or offset designs to reach tight spaces.

Using an O2 sensor wrench reduces the risk of damaging the sensor or its surrounding parts. Regular tools may apply uneven pressure, causing the sensor to break. In contrast, O2 sensor wrenches are engineered to apply efficient and precise torque.

These wrenches are commonly used by automotive professionals and DIY car enthusiasts. They are available in different sizes and designs to accommodate various vehicle models. Investing in an O2 sensor wrench is essential for safely removing or installing oxygen sensors, ensuring your car operates smoothly.

Importance of Using the Correct O2 Sensor Wrench

Using the correct O2 sensor wrench is vital for maintaining your vehicle’s performance. Oxygen sensors need precise handling to avoid damage during installation or removal.

Ensure Proper Functioning of the Sensor

Choosing the right tool ensures the oxygen sensor functions effectively. Faulty sensors can impact fuel efficiency and emissions.

Prevent Damage to Nearby Components

Incorrect tools risk damaging other engine parts. The proper wrench prevents scratches or bends in tight spaces.

Guarantee a Secure Fit

A well-designed O2 sensor wrench provides precise torque. This helps to tighten or loosen the sensor without slippage or misalignment.

Save Time and Effort

The correct wrench is easier to use in hard-to-reach locations. It eliminates the need for multiple tools or improper methods.

Avoid Costly Repairs

Proper usage prevents damage that might require expensive repairs. Using the correct tool is an investment in long-term efficiency.

Improve Engine Performance

Properly installed oxygen sensors help the engine maintain the optimal air-to-fuel ratio. This supports smoother operation and reduces harmful emissions.

Using the correct O2 sensor wrench ensures safety, efficiency, and cost-effectiveness in car maintenance.

Types of O2 Sensor Wrenches

Types of O2 Sensor Wrenches

O2 sensor wrenches come in various types, each suited to specific needs. Choosing the right one depends on the sensor’s location and your vehicle type. Below are the common types:

Socket-Style O2 Sensor Wrenches

- These wrenches resemble a standard deep socket.

- They feature a cutout or slot to accommodate the sensor’s wiring.

- Suitable for sensors that are easily accessible.

Crowfoot O2 Sensor Wrenches

- They have an open-ended design for tight spaces.

- Ideal for sensors in hard-to-reach areas like near the firewall.

- Offer a good grip while preventing damage to the wiring.

Offset O2 Sensor Wrenches

- These wrenches have an angled or offset head.

- The design allows better access to sensors in awkward positions.

- Reduces hand strain during use.

Adjustable O2 Sensor Wrenches

- These wrenches have an adjustable jaw to fit various sensor sizes.

- They are versatile but may lack the precision of fixed-size wrenches.

- Useful for working on multiple vehicle types.

Ratcheting O2 Sensor Wrenches

- These come with a ratcheting mechanism for quicker operations.

- They are efficient when dealing with stubborn or old sensors.

- Ideal for professionals who need to save time.

Selecting the proper type of O2 sensor wrench ensures safe and efficient handling. Each type offers distinct advantages based on the task and vehicle requirements. Consider your specific needs and the sensor’s location when making your choice.

Key Features

When selecting the right O2 sensor wrench, it’s essential to focus on key features. These features ensure the wrench is effective, durable, and easy to use. Below are the key aspects to consider when buying an O2 sensor wrench:

Material and Durability

- Choose a wrench made from high-quality materials, such as chrome vanadium steel.

- Durable materials resist wear and withstand high torque during use.

- Avoid cheap materials, as they may break or bend under pressure.

Fit and Compatibility

- Look for a wrench designed to fit the common sizes of O2 sensors.

- Ensure compatibility with different vehicle models and sensor types.

- Some wrenches are adjustable to suit a wider range of sensors.

Design and Accessibility

- Opt for a wrench with a cutout or slot for sensor wiring.

- Select a model with a flexible or offset design for better access.

- Consider a ratchet mechanism for quicker and easier operations.

Grip and Torque Control

- Check for a non-slip grip to ensure safe handling.

- Look for a wrench that applies even and precise torque.

- Proper grip and torque prevent sensor damage during installation or removal.

Ease of Use

- Choose a wrench that simplifies work in tight or awkward spaces.

- Lightweight wrenches are easier to maneuver and reduce hand fatigue.

- Ensure the tool is user-friendly for both beginners and professionals.

Specialized Features

- Features like a pivoting head improve flexibility in hard-to-reach areas.

- Ratcheting mechanisms can speed up repetitive jobs significantly.

- Magnetic inserts or additional adapters enhance versatility.

By focusing on these features, you can select an O2 sensor wrench that meets your needs. A good wrench not only ensures easy sensor handling but also safeguards your vehicle from unnecessary damage.

How to Properly Use an O2 Sensor Wrench

Using an O2 sensor wrench correctly ensures the sensor is installed or removed without damage. Improper use can affect the sensor’s functioning or harm nearby car components. Follow these steps to use the wrench safely and effectively:

Gather Required Tools and Equipment

- Have the O2 sensor wrench matching your sensor type.

- Prepare a socket driver or ratchet if needed.

- Ensure gloves and safety goggles are available for protection.

Locate the Oxygen Sensor

- Refer to your vehicle’s manual to find the sensor location.

- Common spots include the exhaust manifold or near the catalytic converter.

- Make sure the engine is off and has cooled down to avoid burns.

Disconnect the Sensor Wiring

- Carefully unplug the sensor’s electrical connector.

- Avoid pulling hard to prevent damaging the wires.

- Use gentle movements to separate the connector.

Position the Wrench Properly

- Fit the O2 sensor wrench over the sensor with the slot around the wiring.

- Ensure the wrench is securely seated to prevent slippage.

- Align the wrench for better leverage, considering tight spaces.

Apply Torque Carefully

- Turn the wrench in the correct direction for removal or installation.

- Use steady pressure to avoid over-tightening or breaking the sensor.

- For stubborn sensors, apply penetrating oil to loosen them.

Install or Replace the Sensor

- Thread the new or cleaned sensor by hand to avoid cross-threading.

- Use the wrench to tighten it securely but not excessively.

- Reconnect the electrical wiring to complete the installation.

Test the Sensor

- Start the engine and confirm the sensor works properly.

- Check for error codes or unusual engine performance.

Following these steps will keep the O2 sensor safe and ensure proper vehicle performance. Always handle the wrench with care to avoid unnecessary repairs or replacements.

Common Mistakes to Avoid

Common Mistakes to Avoid

Using an O2 sensor wrench requires proper technique and care. Avoid these common mistakes to ensure safe and effective use:

Incorrect Wrench Selection

- Using a regular wrench can damage the sensor.

- Choose a wrench designed specifically for O2 sensors.

- Ensure the wrench matches the sensor’s size and location.

Improper Torque Application

- Applying too much force can break the sensor.

- Always use steady, controlled pressure.

- Avoid over-tightening or under-tightening.

Ignoring Sensor Wiring

- Mishandling the wiring can cause damage.

- Use a wrench with a cutout designed for sensor wiring.

- Ensure the wiring is properly aligned during use.

Neglecting to Cool Down the Engine

- Working on a hot engine can lead to burns.

- Wait until the engine cools fully.

- Wear protective gear to minimize risks.

Skipping Penetrating Oil for Stubborn Sensors

- Dry sensors may require additional effort to remove.

- Apply penetrating oil for easier loosening.

- Let the oil sit for a few minutes before trying again.

Cross-Threading During Installation

- Improper alignment can cause cross-threading.

- Start threading the sensor by hand to avoid misalignment.

- Use the wrench gently to finish installation.

Overlooking Testing After Installation

- Failing to check the sensor may lead to performance issues.

- Start the engine and verify sensor functionality.

- Ensure no error codes appear after installation.

Avoiding these mistakes ensures your O2 sensor operates efficiently and lasts longer. Handle the wrench with care for optimal results.

Recommended Brands and Models

Choosing a reliable O2 sensor wrench involves selecting trusted brands and models. Quality tools ensure safe and effective use. Below are some highly recommended O2 sensor wrench brands and their popular models:

GearWrench

- Known for durable automotive tools.

- Offers high-quality offset and crowfoot O2 sensor wrench designs.

- GearWrench 41740 is a popular choice for tough-to-reach sensors.

Lisle

- Specializes in innovative automotive repair tools.

- Lisle 13300 is a trusted socket-style O2 sensor wrench.

- Provides durability and easy operation for various vehicle types.

ARES

- Offers professional-grade tools at reasonable prices.

- ARES 70317 features a slotted design for better wiring protection.

- Ideal for DIY car enthusiasts and auto professionals.

OEMTOOLS

- Focuses on precision and efficiency in tool manufacturing.

- OEMTOOLS 25257 is an adjustable O2 sensor wrench.

- Provides versatility for handling different sensor sizes.

Craftsman

- Renowned for strong and long-lasting automotive hand tools.

- Craftsman crowfoot-style wrenches excel in tight spaces.

- Great for sensors located near exhaust manifolds.

Performance Tool

- Offers a range of budget-friendly automotive tools.

- Performance Tool W86560 is a durable socket-type wrench.

- Suitable for casual users seeking affordable options.

Snap-on

- A respected brand in professional-grade automotive equipment.

- Snap-on specialized ratcheting wrenches are top-rated for difficult tasks.

- Known for precise torque application and durability.

Investing in reliable brands minimizes risks during sensor installation or removal. Choose models based on your specific needs and work environment. High-quality O2 sensor wrenches enhance efficiency and protect your vehicle.

Tips for Maintaining and Storing

Tips for Maintaining and Storing

Proper care enhances the lifespan and efficiency of your O2 sensor wrench. Follow these simple guidelines:

Clean After Each Use

- Wipe the wrench to remove dirt and grease.

- Wash thoroughly if exposed to oily surfaces.

- Avoid abrasive cleaners that may harm the wrench.

Lubricate Moving Parts

- Apply lubricant to ratcheting or adjustable mechanisms.

- Use rust-preventive oil to prevent corrosion.

- Ensure excess lubricant is wiped off after application.

Avoid Excessive Force

- Do not over-tighten or misuse the wrench.

- Store separately to prevent damage from heavy tools.

- Inspect for wear or fractures regularly.

Store in a Safe Place

- Keep the wrench in a dry and cool environment.

- Use a toolbox or pouch for organization.

- Avoid places with high moisture to prevent rust.

Inspect Periodically

- Check for bends, rust, or wear signs.

- Replace damaged wrenches immediately.

- Ensure slots and cutouts are free of debris.

Label for Easy Identification

- Mark the wrenchsize or model for quick access.

- Store grouped by size if owning multiple wrenches.

- Keep separate from non-automotive tools.

Proper maintenance ensures your O2 sensor wrench performs efficiently and lasts longer. Regular care reduces replacement costs and improves safety during use.

Frequently Asked Questions

Can I use a regular socket instead?

Sometimes. But limited space often blocks full rotation. An o2 sensor wrench offers better access.

Do I need special lubricant?

Penetrating oil like PB Blaster works best. It breaks down rust without harming metal.

Is the sensor always on the exhaust?

Yes. All models thread into exhaust piping. Location varies by engine layout.

What if the sensor breaks off?

Stop immediately. Use an extractor kit. Drill carefully to avoid damaging the bung.

Are anti-seize compounds safe?

Yes. Apply sparingly on threads. Prevents future seizing. Do not get it on the sensing element.

Can I reuse the old sensor?

No. Once removed, seals degrade. Performance drops. Always replace with a new unit.

How do I know which sensor to replace?

Use an OBD2 scanner. It identifies upstream or downstream faults. Check freeze frame data.

Do all vehicles have two sensors?

Most have at least two. Some newer models include four. Refer to your owner’s manual.

Final Thoughts

Final Thoughts

Using the right o2 sensor wrench transforms a frustrating job into a simple task. It provides access, control, and safety in tight exhaust areas. Mechanics at all levels benefit from owning one.

From design to durability, every detail supports efficient repairs. Whether replacing a faulty sensor or upgrading your toolkit, this tool delivers value. Its role in vehicle maintenance is undeniable.

As emissions standards grow stricter, oxygen sensors remain vital. Quick diagnosis and replacement keep cars running cleanly. An o2 sensor wrench ensures the job gets done right.

The popularity of this tool continues to rise. It solves a common problem faced by millions of drivers. Make sure yours meets both functional needs and build quality standards.