Wrench Socket Essentials: Everything You Need for DIY

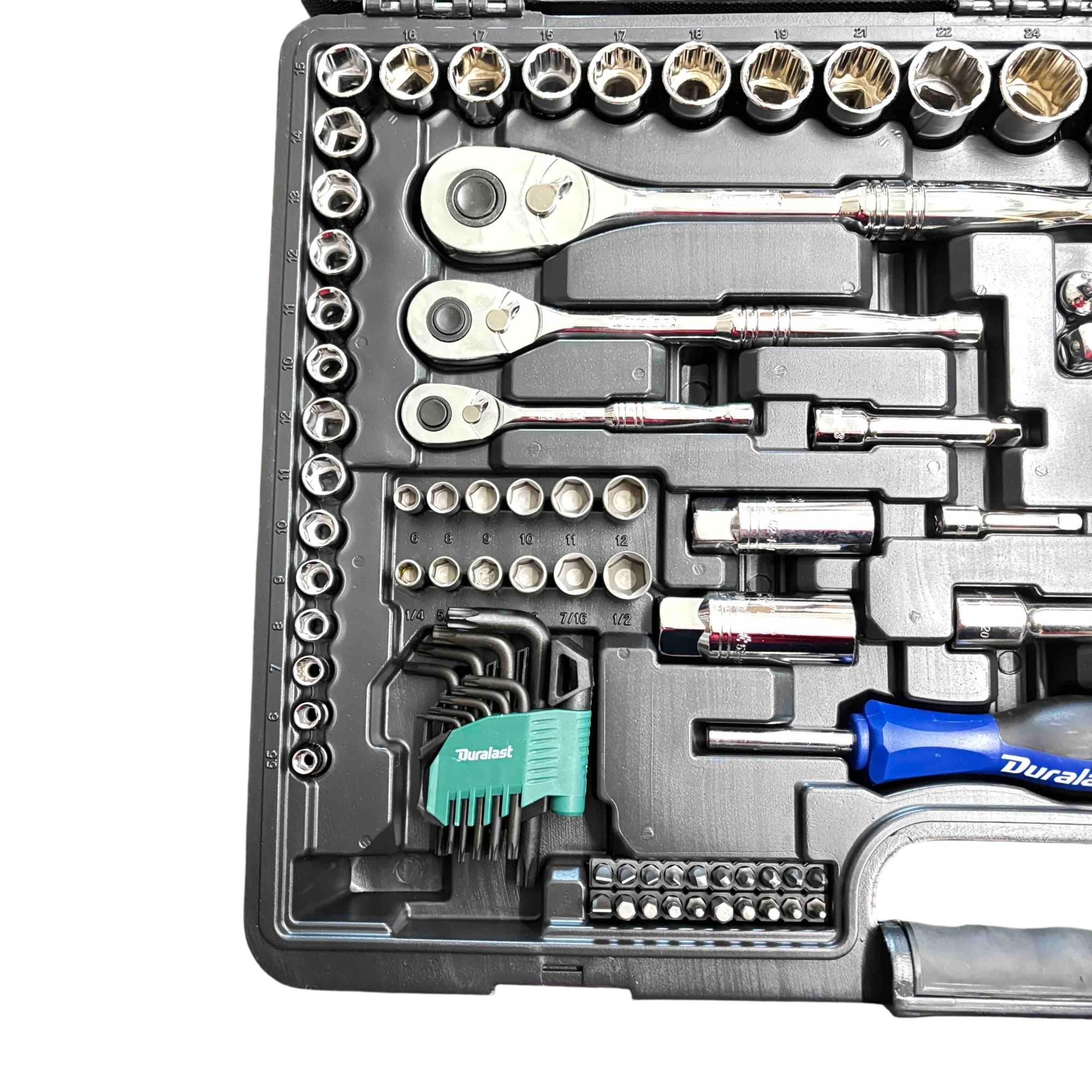

A wrench socket is a vital tool for anyone working with nuts and bolts. It attaches to a ratchet or breaker bar and fits over fasteners of different sizes. This combination allows users to tighten or loosen connections quickly. Whether you’re fixing a car, assembling furniture, or repairing machinery, a wrench socket saves time and effort. Because of its versatility, it’s found in nearly every toolbox.

In addition, wrench sockets come in various shapes, materials, and drive sizes. They work with both metric and standard measurements. Some are designed for deep access. Others offer quick release features. Knowing how to choose the right one improves performance and safety. As a result, understanding the wrench socket system is essential for DIYers and professionals alike.

Overview of Types

Overview of Types

Wrench sockets are essential tools in various applications. They come in different types and sizes to meet specific needs. Choosing the right wrench socket enhances efficiency and safety.

Standard sockets

Standard sockets are the most common type. They are designed for general use in straightforward applications. Standard sockets usually fit shallow fasteners and work well in less confined spaces. They are ideal for tasks like assembling furniture or small maintenance jobs.

Deep sockets

Deep sockets have an elongated design. They are perfect for reaching nuts or bolts in deeper spaces. These sockets excel in situations where the bolt or nut is recessed. For instance, in automotive repairs, deep sockets provide access to wheel nuts or spark plugs. Their design delivers better grip and versatility for tricky tasks.

Impact sockets

Impact sockets are made for high-torque tools like impact wrenches. They are constructed from durable materials like chrome molybdenum for extra strength. Impact sockets are designed to handle heavy-duty projects without cracking under pressure. They are commonly used in industrial settings where there is frequent use of powered tools. Their ability to withstand high impact ensures longevity and efficiency in demanding tasks.

Key Factors

Selecting the right wrench socket is important for efficiency and safety. Various factors impact the choice of a wrench socket.

Material and durability

Consider the material when choosing a wrench socket. Durable sockets last longer and withstand tougher tasks. Chrome vanadium and chrome molybdenum are common materials used in wrench sockets. Chrome vanadium is great for routine tasks, while chrome molybdenum suits impact sockets. Ensure the socket material can handle the pressure and torque required by your tool. Opt for well-constructed sockets to avoid breakage during use.

Compatibility with bolt sizes

Wrench sockets must fit the bolt or nut properly. A good fit prevents slipping and damage. Measure the size of bolts before selecting a socket. Sockets come in metric and SAE sizes to match different specifications. Metric sizes fit bolts measured in millimeters, while SAE sizes match inches. Check the fastener type to choose the right size. Always pick sockets that snugly fit the bolt or nut.

Drive size options

Drive size affects the tool’s compatibility and performance. Common drive sizes include 1/4-inch, 3/8-inch, and 1/2-inch. Smaller drive sizes are ideal for precision tasks or tight spaces. Larger drive sizes offer more torque for heavy-duty work. Match the drive size to your socket wrench or impact tool. Larger sizes handle high torque but may be bulkier. Ensure your socket drive size aligns with the tool requirements for optimal results.

Applications

Applications

Wrench sockets are versatile tools with applications in various fields. Different types of wrench sockets suit distinct tasks, enhancing efficiency and precision in daily activities.

Automotive repairs

Wrench sockets play a crucial role in automotive repairs. Deep sockets are particularly useful for removing recessed nuts and bolts. Tasks like changing wheel nuts, repairing engines, or accessing spark plugs often require deep sockets. Impact sockets are also widely employed in this field as they handle high torque from impact wrenches. Their durability helps mechanics avoid damage while working on heavy-duty tasks.

Industrial uses

In industrial settings, wrench sockets are indispensable for maintenance and assembly tasks. Impact sockets are commonly used due to their ability to withstand high torque. Industries such as manufacturing, construction, and heavy equipment repair rely heavily on impact sockets. These sockets help handle fast-paced and repetitive demands effectively. Standard sockets may also be used for simpler adjustments or smaller machinery.

Home improvement tasks

Home improvement involves various small repairs and DIY projects. Standard sockets are ideal for routine household tasks like furniture assembly or basic appliance repairs. Deep sockets may come into play for harder-to-reach fasteners in tight spaces. Homeowners prefer sockets with sturdy builds to ensure reliability when tackling diverse household challenges. Using compatible wrench sockets can make these projects quicker and more efficient.

Comparison: Metric vs. SAE

Metric and SAE wrench sockets have distinct features that suit different applications. Understanding their differences helps ensure proper usage and efficiency.

Key differences

Metric sockets measure bolt sizes in millimeters, while SAE sockets use inches. Metric sizes follow a decimal-based system, making them ideal for bolts globally, especially in countries using metric standards. SAE sockets are commonly used in the United States due to imperial measurement systems.

Metric sockets are precise for bolts used in automotive and machinery requiring exact measurements. SAE sockets fit bolts and nuts that adhere to inch-size standards, enhancing compatibility with tools made for American markets. Proper sizing prevents slipping or damage during tasks.

When to use metric sockets

Metric sockets are widely used in industries where bolts and fasteners adhere to millimeter dimensions. They are essential in automotive repairs, as most modern cars use metric bolts. Global manufacturers typically standardize on metric systems for hardware, making metric sockets versatile for repairs.

Use metric sockets when working on international machinery or tools designed with metric fittings. They offer precise fit and compatibility, reducing wear on bolts and ensuring job efficiency. Professional mechanics rely on metric sockets for accuracy in demanding applications.

When to use SAE sockets

SAE sockets are invaluable for tools and machinery built with imperial measurements. They excel in applications like older vehicle repairs, where bolts often adhere to inch-based specifications. Home improvement projects in the United States may also demand SAE sockets due to legacy designs.

Choose SAE sockets for work with American-made machinery, vintage cars, or specific domestic appliances. They provide a snug fit for tools in imperial systems, enhancing control and reducing wear. SAE sockets remain essential for tasks involving traditional American standards.

Importance of Socket Accessories

Importance of Socket Accessories

Socket accessories improve the functionality and versatility of wrench sockets. These tools assist in reaching difficult angles, increasing grip, and maintaining precision. Whether for professional repairs or DIY projects, socket accessories ensure smoother and safer operations. Here are the top essentials to consider.

Extensions and adapters

Extensions and adapters enable access to hard-to-reach areas. They are useful in automotive repairs and machinery maintenance. Adapters help match sockets with different drive sizes. For example, they allow a larger socket to fit a smaller wrench or vice versa. Investing in reliable extensions and adapters enhances flexibility during complex tasks.

Universal joints

Universal joints allow the socket to pivot at different angles. This feature helps handle bolts or nuts located in tight or awkward positions. They are essential in situations where straight access is impossible. Universal joints are frequently used in automotive repairs, especially for engine compartments or suspension systems. Choose sturdy universal joints to ensure smooth movement and avoid damage.

Torque settings

Torque settings promote accuracy and prevent over-tightening or loosening of fasteners. Use a torque wrench equipped with appropriate settings to apply the right force. Torque-specific accessories ensure consistent performance, especially for critical tasks like assembling machinery or securing hardware. Maintaining proper torque settings not only enhances safety but also extends the lifespan of bolts and nuts.

Maintenance Tips

Proper maintenance of wrench sockets ensures durability and optimal performance. Follow these tips to keep them in excellent condition.

Cleaning and storage

- Clean sockets after use: Remove dirt, grease, or debris with a clean cloth or brush. Use mild soapy water if required, ensuring they are completely dry before storing.

- Avoid exposure to moisture: Store socket tools in a dry environment. Moisture can lead to rust, affecting their usability.

- Organize properly: Arrange sockets in a dedicated storage case or socket rail. This keeps them easily accessible and prevents misplacement or damage.

- Inspect regularly: Check for wear, cracks, or deformation. Replace damaged sockets to avoid accidents during use.

- Avoid overcrowding storage: Ensure each socket has adequate space to prevent scratches or dents.

Preventing rust and corrosion

- Apply protective coatings: Use lubricants or anti-rust sprays to coat wrench sockets. This adds an extra layer of protection against rust.

- Store in a low-humidity area: Keep sockets away from damp or humid locations. Consider using dehumidifiers if needed.

- Use silica gel packs: Add silica gel packs to your storage box to reduce moisture buildup.

- Avoid storing wet tools: Always dry your sockets thoroughly after cleaning or usage to prevent corrosion.

- Choose high-quality materials: Invest in corrosion-resistant sockets made from chrome vanadium or similar materials. This reduces the risk of rust over time.

By following these maintenance practices, you can keep your wrench sockets in top condition. Regular care not only extends their lifespan but also enhances performance and safety during use.

Common Mistakes to Avoid

Common Mistakes to Avoid

Using wrench sockets correctly ensures safety and efficiency. Avoiding common mistakes prevents damage and enhances precision.

Improper size selection

Incorrect socket size is a frequent error. It can damage bolts or the socket itself. Always measure bolts or nuts before choosing a socket. Metric sockets fit millimeter-sized bolts, while SAE sockets fit inch-sized ones. A tight fit reduces slipping and wear on the fastener. Using the wrong size may strip bolts or round their edges. Carry a range of sizes to ensure proper fit during tasks. If unsure, use a digital caliper to measure bolt dimensions accurately.

Using the wrong drive type

Matching the drive type to your tool is crucial. Each drive size offers different torque and control levels. Using a socket with the wrong drive size can lead to inefficiency or damage. For lighter tasks, a 1/4-inch drive is ideal. For heavy-duty jobs, opt for a 1/2-inch drive. Adapters should be used carefully to prevent torque loss. Avoid forcing a mismatch, as this may harm the tool or socket. Always confirm the compatibility of your wrench and socket before starting any project.

By avoiding these common mistakes, you can improve efficiency and protect your wrench sockets. Proper usage enhances both their longevity and your task accuracy.

Frequently Asked Questions

Common Concerns Answered Clearly

Can I use a socket without a ratchet? Yes. Attach it to an extension bar and use a wrench. Manual turning still works.

Are all brands compatible? Mostly yes. SAE standards ensure interchangeability. Some premium lines fit tighter.

How do I measure socket size? Check the stamp inside or on the side. Use calipers if unreadable.

What does “6-point” mean? It contacts six sides of the bolt. Offers stronger grip than 12-point.

Can I use adapters safely? In moderation. They add stress points. Avoid in high-torque situations.

Are magnetic sockets safe? Yes. Magnets help hold screws. Won’t damage electronic devices.

How often should I replace sockets? Only when cracked, stripped, or bent. Quality ones last years.

Can I clean sockets in a tumbler? Yes. Media tumblers remove rust. Use non-corrosive polish.

Final Thoughts

Make a Smart Investment in Your Toolbox

Selecting the best wrench socket means balancing quality, size, and function. Each factor contributes to overall success. By focusing on durable materials and proper fit, you ensure lasting performance.

Over time, owning a complete, organized set increases convenience. Whether fixing a bike or rebuilding an engine, having the right socket makes a difference. Proper care enhances durability and reliability.

Ultimately, a wrench socket proves itself as an essential tool. It merges strength, precision, and efficiency in one simple design. As technology evolves, its role remains strong across industries.

To conclude, embracing a quality wrench socket improves daily tasks. It solves common problems like stuck bolts and slow repairs. Simultaneously, it boosts confidence through reliable performance.

Whether new to mechanics or expanding your kit, now is an excellent time to invest. With countless designs and growing innovation, wrench socket will continue meeting diverse needs. Make the smart choice today—your projects depend on it.