Standard Wrench Sizes: Guide to Common SAE Measurements

Understanding standard wrench sizes is essential for anyone working with nuts, bolts, and fasteners. Whether you’re fixing a car, assembling furniture, or repairing plumbing, having the right wrench makes the job easier and safer. Using the wrong size can strip threads, damage tools, or cause injury. That’s why knowing which wrench fits which bolt matters. Standard wrench sizes come in two main systems: SAE (imperial) and metric. Each system has its own set of measurements. These are based on the width across the flats of a nut or bolt head.

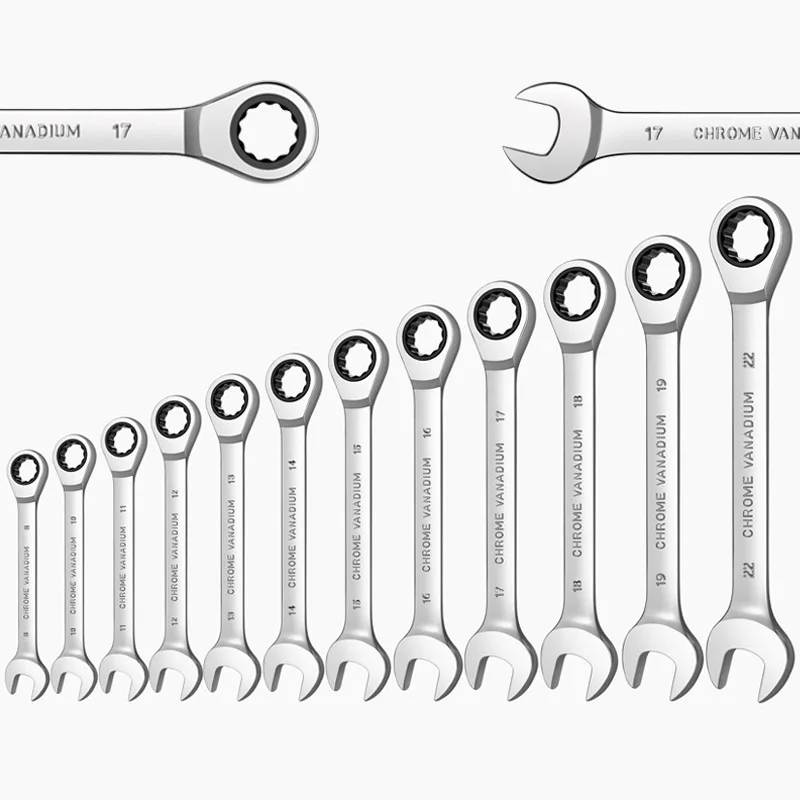

Moreover, wrenches come in various types. Open-end, box-end, combination, adjustable, and socket wrenches all serve different purposes. Each one uses the same sizing principles. Mechanics, DIYers, and engineers rely on these standards daily. They ensure compatibility between tools and hardware. In the U.S., SAE sizes dominate automotive and household use. Across most of the world, metric sizes are standard. Some toolkits include both. This provides flexibility for mixed projects. Let’s explore the details of standard wrench sizes and how to choose the right ones.

Understanding the Two Main Measurement Systems: SAE vs Metric

Understanding the Two Main Measurement Systems: SAE vs Metric

Standard wrench sizes fall into two measurement systems: SAE and metric. SAE stands for Society of Automotive Engineers. It uses inches and fractions of an inch. Common SAE sizes include 1/4″, 5/16″, 3/8″, 7/16″, and so on. These are widely used in the United States. Most American-made cars, appliances, and machinery use SAE fasteners.

Metric sizes, on the other hand, use millimeters. They are common in Europe, Asia, and many modern vehicles. Examples include 8mm, 10mm, 12mm, and 14mm. Many imported cars, bikes, and electronics use metric hardware. As global manufacturing grows, metric tools become more necessary.

It’s important to know which system your project requires. Mixing them leads to mistakes. A 10mm wrench may fit a 3/8″ bolt loosely. This increases the risk of slippage and damage. Always check the fastener before selecting a wrench. Look for markings on the bolt head. They often indicate the size and system.

Many toolkits now offer dual-scale labeling. This helps users switch between systems. For full versatility, keep both SAE and metric sets. Knowing standard wrench sizes in both systems prepares you for any task.

Common SAE Wrench Sizes and Their Typical Applications

SAE wrench sizes are still widely used in North America. The most common sizes range from 1/4″ to 1″. Each size serves specific functions. Smaller sizes handle delicate tasks. Larger ones tackle heavy-duty jobs.

A 1/4″ wrench fits small screws and fittings. It’s useful in electronics and appliances. 5/16″ works on light automotive parts. It fits spark plugs and brake line nuts. 3/8″ is one of the most popular sizes. It appears in engines, transmissions, and home fixtures.

7/16″ handles fuel lines and suspension components. 1/2″ is strong enough for lug nuts and brackets. 9/16″ fits larger bolts in trucks and machinery. 5/8″ and 3/4″ are less common but needed for big equipment. 7/8″ and 1″ are rare but appear in industrial settings.

These sizes come in open-end, box-end, and socket forms. Combination wrenches feature both ends. This saves time switching tools. Craftsman, Stanley, and Husky make reliable SAE sets. Always match the wrench to the bolt. Avoid forcing a fit. Proper use extends tool life. Keep a labeled organizer for quick access.

Popular Metric Wrench Sizes and Where You’ll Use Them

Popular Metric Wrench Sizes and Where You’ll Use Them

Metric wrench sizes dominate global manufacturing. Most modern vehicles use metric fasteners. Bicycles, motorcycles, and European cars rely on mm-based tools. Even some American-made machines now use metric hardware.

Common metric sizes start at 6mm. This fits small bolts in electronics and trim panels. 8mm is frequent in engine covers and sensors. 10mm appears everywhere. It’s one of the most used sizes. It fits battery terminals, brackets, and hose clamps.

12mm handles suspension links and caliper bolts. 13mm fits exhaust manifold nuts. 14mm is common on oil pans and control arms. 15mm and 17mm work on larger suspension and drivetrain parts. 19mm and 21mm deal with axle nuts and heavy components.

These sizes are found in German, Japanese, and Korean vehicles. BMW, Honda, Hyundai, and Toyota all use metric systems. Bicycle mechanics depend on 4mm to 6mm hex keys. However, wrenches are still needed for outer nuts.

Socket sets in metric are just as common. Ratchets and extensions improve access. Always verify the size before turning. A 10mm wrench won’t fit a 3/8″ bolt perfectly. Precision prevents damage. Investing in a full metric set pays off over time. Standard wrench sizes in metric are not optional—they’re essential.

How to Read Wrench Size Markings on Tools and Fasteners

Reading wrench size markings is a basic but vital skill. Most wrenches have the size stamped on the handle or head. Look closely near the opening. SAE sizes show fractions like “1/2” or “3/8”. Metric sizes display numbers like “10mm” or “14mm”.

Some tools list both systems. For example, “1/2” / 13mm” means it fits both sizes. This helps when working on mixed hardware. Dual-scale ratchets also exist. They make transitions smoother.

On fasteners, look at the top of the bolt head. Many have numbers or letters. “M8” means metric 8mm diameter. “1/2-20” means SAE 1/2 inch with 20 threads per inch. These marks guide tool selection.

If no marking exists, measure the distance across the flats. Use a ruler or caliper. For SAE, measure in inches. For metric, use millimeters. Match that number to your wrench set.

Always double-check. A 12mm wrench may slide onto a 1/2″ bolt. But it will be loose. This risks rounding the corners. Accurate reading ensures a snug fit. It protects both tool and fastener.

Choosing the Right Wrench Type for Different Jobs

Choosing the Right Wrench Type for Different Jobs

Not all wrenches are the same. Each type suits different situations. Open-end wrenches have a U-shaped end. They fit over nuts quickly. They’re great for tight spaces. However, they can slip easily under high torque.

Box-end wrenches surround the nut completely. They grip all six sides. This reduces slippage. They’re ideal for stubborn or rusted bolts. But they need space to slide on. They don’t work well in deep recesses.

Combination wrenches have both ends. One side is open. The other is boxed. This gives flexibility. You can flip the tool without changing wrenches. Most mechanics prefer this style.

Adjustable wrenches, like crescent wrenches, change size. They fit multiple nuts. Useful in emergencies. But they’re less precise. They can damage soft metals. Not recommended for regular use.

Socket wrenches use interchangeable heads. They connect to a ratchet. This allows continuous turning without removing the tool. Ideal for repetitive tasks. Extension bars reach deep bolts.

Torque wrenches apply exact force. Used in engines and critical joints. Prevents over-tightening. Essential for safety. Choose the right type based on access, strength, and precision needs.

Building a Complete Wrench Set Based on Standard Sizes

Creating a complete wrench set starts with standard wrench sizes. Include both SAE and metric options. Begin with the most common sizes. For SAE: 1/4″, 5/16″, 3/8″, 7/16″, 1/2″, 9/16″, 5/8″, 11/16″, 3/4″. These cover 90% of household and auto repairs.

For metric: 8mm, 10mm, 12mm, 13mm, 14mm, 15mm, 17mm, 19mm. Add 6mm and 21mm for specialty jobs. Get each size in open-end, box-end, and socket form. Combination wrenches save space.

Include adjustable wrenches as backups. A 6-inch and 10-inch model handle odd sizes. Add a torque wrench for engine work. Calibrate it regularly. Socket sets should have shallow and deep sockets.

Store tools in a roll-up case or tray. Label each slot. This speeds up retrieval. Keep them clean and dry. Rust ruins performance. Inspect for wear. Replace damaged wrenches.

Buy quality brands. GearWrench, Tekton, and IRWIN offer durability. Cheap tools bend or strip. Invest once for long-term use. A full set makes you ready for anything.

Frequently Asked Questions

Frequently Asked Questions

What are the most common standard wrench sizes?

For SAE: 3/8″, 7/16″, 1/2″. For metric: 10mm, 12mm, 14mm.

Can I use a metric wrench on an SAE bolt?

Sometimes, but not safely. Close sizes may fit loosely. This damages the fastener.

How do I know if my wrench is worn out?

Check for rounded openings. If it slips easily, replace it.

Are standard wrench sizes universal?

Most are. But always confirm the system—SAE or metric.

Do I need both SAE and metric sets?

Yes. Modern projects often mix both systems.

What size wrench fits a standard spark plug?

Typically 5/8″ (SAE) or 16mm (metric). Check your vehicle manual.

Can I use pliers instead of a wrench?

Pliers increase slippage risk. Use only in emergencies.

Why does my wrench feel loose on the bolt?

The size is wrong. Or the tool or bolt is worn. Never force it.

Final Thoughts on Mastering Standard Wrench Sizes

Final Thoughts on Mastering Standard Wrench Sizes

Knowing standard wrench sizes improves every repair job. It boosts efficiency and safety. Whether you work on cars, bikes, or home fixtures, the right tool matters. SAE and metric systems coexist. Both are necessary for modern tasks. Owning a complete set saves time and frustration.

Always match the wrench to the fastener. Avoid improvisation. Precision prevents damage. Learn to read size markings. Store tools properly. Maintain them regularly. Quality tools last longer and perform better.

As technology evolves, so do fasteners. Yet, standard wrench sizes remain a constant. They form the backbone of mechanical work. From garages to factories, they are indispensable. For any DIYer or professional, mastering standard wrench sizes is not optional—it’s essential.