Tenths Tape Measure Guide: Essential for Builders & Surveyors

When embarking on any measuring task, accuracy is paramount. Whether you’re a professional contractor, a DIY enthusiast, or someone tackling home improvement projects, a reliable tool is essential. Enter the tenths tape measure—a precision instrument designed to provide meticulous measurements with ease. This article delves into the features, benefits, and various applications of tenths tape measures, helping you understand why they are indispensable in both professional and personal settings.

What Is a Tenths Tape Measure?

What Is a Tenths Tape Measure?

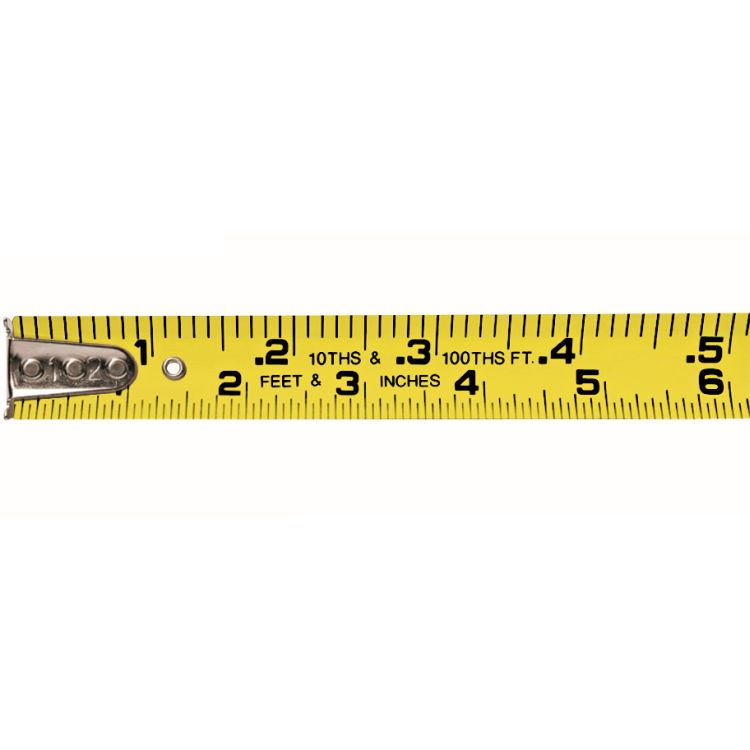

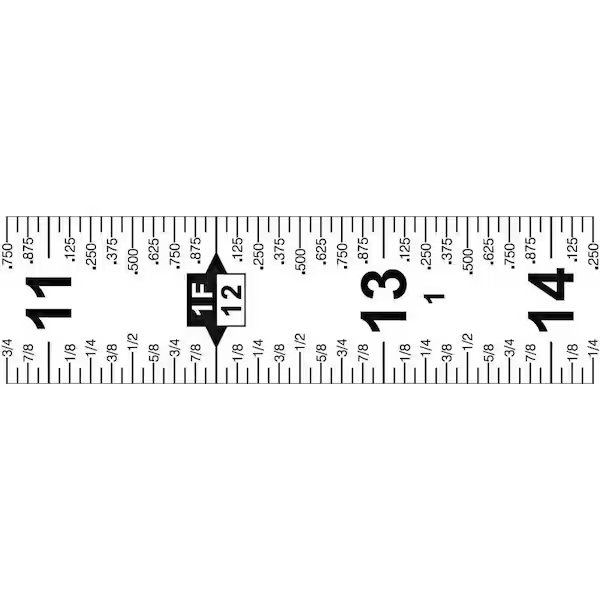

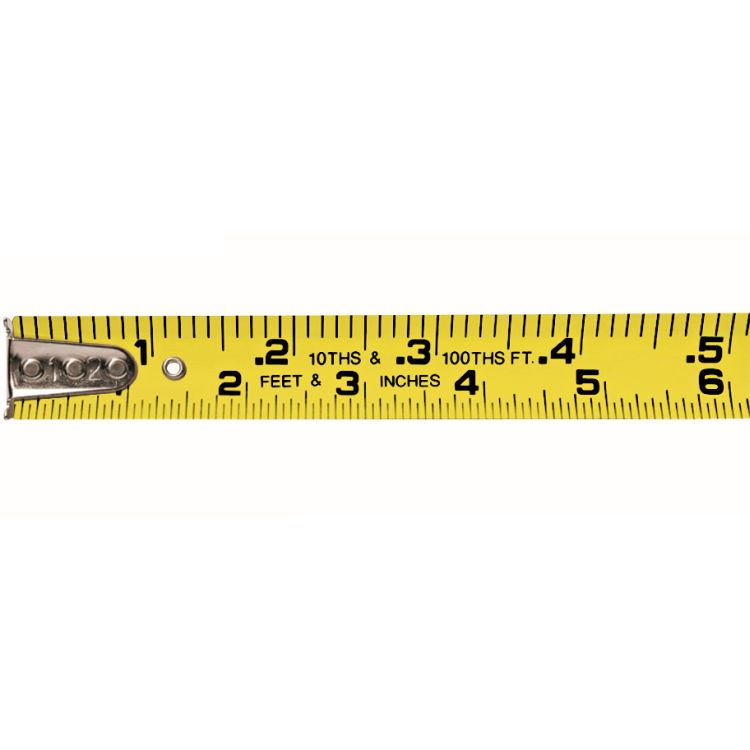

A tenths tape measure is a unique measuring tool. Instead of standard fractions, it uses the decimal system to divide measurements. Each inch is divided into 10 equal parts, called tenths. This makes it suitable for tasks that demand precise, decimal-based readings. Professionals often favor it in industries like engineering, construction, and surveying.

Key Features of Tenths Tape Measures

- Decimal System Display: These tape measures break inches into 10 parts instead of fractions.

- Clear Markings: They feature clear and easy-to-read lines for high accuracy.

- Durable Material: Usually made from strong materials to last under repeated use.

- Variety in Lengths: They come in lengths that suit projects of different scales.

- Specialized Use: Designed for professionals who need precise decimal measurements.

How It Differs from Standard Tape Measures

- Measurement Units: Tenths tape measures use decimals. Standard tape measures typically use fractions.

- Precision: Tenths tape measures provide more detail, ideal for exact measurements.

- Applications: Professionals use tenths tape measures for engineering and surveying. Standard tape measures are more common for general use.

- Ease of Conversion: Decimal measurements are easier to convert into other unit systems. Standard tape measures may require extra steps for conversion.

- Markings: Standard tape measures often include feet or metric units, while tenths tape measures focus on decimals.

Uses and Applications of Tape Measurements

Tenths tape measures are essential tools in specific fields and scenarios. Their precision makes them ideal for detailed tasks. Professionals rely on them when accuracy is critical.

Industries That Rely on Tenths Tape Measures

- Engineering: Engineers use tenths tape measures for designing and constructing accurate structures. Precision is vital.

- Surveying: Surveyors depend on tenths tape measures for measuring land boundaries and elevation differences.

- Construction: Builders rely on them for precision in layouts and installations, ensuring projects meet specifications.

- Architecture: Architectural designs often require decimal-based measurements for intricate plans.

- Manufacturing: Manufacturing processes use tenths tape measures for precise component fabrication and assembly.

Common Scenarios Where Tenths Measurements Are Crucial

- Land Survey: Professionals use tenths tape measures to map terrain and define property lines accurately.

- Building Layouts: These tape measures ensure perfect alignment of foundations and structures.

- Pipe Installation: Accurate decimal measurements are crucial for fitting pipes in restricted spaces.

- Machine Parts Fabrication: Tenths tape measures help create correctly-sized components for industrial machines.

- Precise Carpentry: Tenths tape measures provide accurate cuts and fit for detailed woodworking projects.

Tenths tape measures offer unmatched precision for complex tasks in various industries. Their applications demonstrate their versatility and importance.

How to Read a Tape Measure Correctly

Reading a tenths tape measure accurately ensures precise measurements for professional tasks. These tools use the decimal system, dividing each inch into ten equal parts. Mastering the process requires understanding the markings and following the right steps.

Understanding the Decimal System in Tenths Measurements

- Inches Divided into Tenths: Each inch on a tenths tape measure is split into 10 equal sections.

- Decimal Markings: Decimal numbers, such as 0.1, 0.2, etc., represent the divisions between inches.

- No Fractions: Unlike standard tape measures, tenths measures only use decimals for clarity.

- Consistent Distances: Each segment is evenly spaced, ensuring accuracy in measurements.

- Alignment with Standards: Decimal-based units work well with other metric systems worldwide.

Step-by-Step Guide to Measuring in Tenths

- Inspect the Tape: Look at the numbers and marks on the tape to understand the layout.

- Identify Zero Point: Start measuring at the “0” marking for accurate results.

- Move to the Desired Length: Extend the tape to the point you want to measure.

- Note the Decimal Point: Find the exact decimal aligned with the object you’re measuring.

- Record the Measurement: Write down the decimal for later calculations.

- Double-Check: Confirm the reading by repeating the measurement if possible.

Properly reading tenths tape measures ensures precise measurements. Understanding decimals and following steps can minimize errors in critical tasks.

Tips for Accurate Tenths Measurements

Tips for Accurate Tenths Measurements

Accurate tenths measurements are essential for precise readings in professional tasks. Following the right techniques and maintaining the tape measure ensures reliability and consistency.

Techniques to Minimize Errors

- Hold the Tape Steady: Ensure the tape doesn’t move during measurement for accurate results.

- Use Flat Surfaces: Measure on smooth surfaces to avoid distortion or uneven readings.

- Proper Alignment: Align the tape measure directly with the object’s edge.

- Read Closely: Observe markings carefully to avoid misinterpreting decimal points.

- Avoid Damage: Prevent tape kinks or wear that can disrupt accuracy.

- Double-Check Readings: Repeat measurements to confirm results and detect errors.

- Use Proper Lighting: Ensure adequate light to clearly see the tape markings.

Importance of Calibration and Proper Maintenance

- Regular Calibration: Check tape accuracy periodically to ensure measurements match decimal standards.

- Clean the Tape: Remove dirt or debris to keep the markings clear and readable.

- Store Safely: Avoid folding, bending, or exposing the tape to extreme temperatures.

- Inspect for Wear: Look for fading or damaged markings that might affect readings.

- Replace When Necessary: Replace worn-out tapes to maintain accurate measurements.

- Avoid Moisture Exposure: Keep the tape dry to prevent rust or corrosion, especially with metal tapes.

By adopting these strategies, professionals can achieve accurate tenths tape measurements consistently.

Choosing the Right Tape Measure

Selecting the right tenths tape measure ensures precision and ease for professional tasks. Various factors and options can guide your decision.

Factors to Consider When Selecting a Tape Measure

- Measurement Length: Choose a tape length suitable for your project’s scale and requirements.

- Material Quality: Opt for durable materials like steel or fiberglass that resist wear and tear.

- Marking Visibility: Look for bright and clear decimal markings for easy readings in different lighting.

- Locking Mechanism: Select tapes with sturdy locks to hold measurements securely in place.

- Portability: Ensure the tape measure is lightweight and compact for easy transport.

- Accuracy Standards: Verify the tape’s accuracy aligns with industry precision requirements.

- User Ergonomics: Check for features like grips or contours for comfortable use over extended periods.

Popular Brands and Models for Tenths Measurements

- Komelon Tenths Tape: Known for its clear decimal markings and sturdy build quality.

- Lufkin Engineer’s Scale: Popular among professionals for its high accuracy and durability.

- CST/Berger Tape: Reliable, with multiple lengths that suit various engineering and surveying needs.

- Keson Decimal Tape: Offers a smooth retraction mechanism and precise measurements for daily use.

- Stanley Decimal Tape: Combines ergonomic design with long-lasting materials for consistent performance.

- Seco Tenths Tape: Features standout markings and tough casing, ideal for fieldwork scenarios.

By evaluating these factors and exploring trusted brands, professionals can find the perfect tenths tape measure for their tasks.

Benefits of Using Tape Measures

Benefits of Using Tape Measures

Tenths tape measures offer significant advantages for many precise and technical measuring tasks. Their unique design and decimal-based system provide valuable benefits, especially for professionals aiming for accuracy.

Precision and Efficiency in Measurements

- High Accuracy: Tenths tape measures divide inches into tenths, making measurements more precise than standard tapes.

- Exact Conversions: Decimal systems simplify calculations and reduce errors when converting measurements to other units.

- Faster Readings: Decimal markings are easy to interpret, speeding up the measurement process.

- Improved Project Output: Accuracy ensures better alignment and fitting, which helps in achieving desired results.

- Consistency Across Tasks: The decimal system ensures measurements remain uniform, especially in large-scale projects.

- Simplicity for Professionals: Professionals appreciate fewer steps to calculate dimensions, enhancing workflow efficiency.

Why Professionals Prefer Tenths Tape Measures

- Versatility: They are ideal for surveying, construction, and engineering projects that need detailed readings.

- Compatibility with Technical Standards: Decimal systems align with metric units, making them globally applicable and useful.

- Ease of Precision Work: Professionals can trust tenths tapes for tasks like calibration, layouts, and machine part designs.

- Reduced Training Time: Team members can quickly learn to use tenths tape measures due to their straightforward design.

- Durability in Field Use: Many tenths tape measures are built to handle tough working conditions and long-term use.

- Time and Cost Savings: Accurate initial measurements reduce rework, saving both time and resources.

These benefits highlight why tenths tape measures are indispensable for demanding projects. Their precision and usability make them a preferred tool across various industries.

Common Challenges and Solutions in Tenths Measurements

Using a tenths tape measure can sometimes present challenges. Knowing the common issues and their solutions can improve measurement accuracy and usability.

Troubleshooting Errors in Tenths Readings

- Misreading Decimal Markings: Decimal points can be overlooked, causing calculation errors. Always double-check the markings carefully.

- Unclear Markings: Worn or faded tape markings can make readings difficult. Replace old or damaged tape measures.

- Tape Stretching: Over time, the tape may stretch, distorting measurements. Periodically verify accuracy using a known standard.

- Skewed Alignment: Misaligned tape can lead to inaccurate readings. Align the tape perfectly with the object’s edge.

- Improper Zero Placement: Failing to start at the zero point can affect accuracy. Always begin at the “0” mark.

- Human Error: Mistakes in recording measurements are common. Recheck and confirm all readings before proceeding.

Overcoming Difficult Measuring Conditions

- Low Light Environments: Poor lighting can make decimals hard to see. Use portable lights for better visibility.

- Uneven Surfaces: Measurements on rough or angled surfaces can be tricky. Flatten the surface or stabilize the tape.

- Windy Outdoors: In windy conditions, the tape may move, causing errors. Secure the tape firmly to objects.

- Wet Conditions: Moisture can affect tape readability or cause rust. Use waterproof tapes or keep the tape dry.

- Restricted Spaces: Tight areas may make extending the tape tough. Use shorter or flexible tapes to adapt.

- Temperature Extremes: Heat can expand or cold can contract the tape. Store tapes at moderate temperatures for accuracy.

By addressing these challenges, professionals can ensure reliable and consistent tenths measurements in all working conditions.

F&Q: Everything You Need to Know

F&Q: Everything You Need to Know

What is the advantage of using a tenths tape measure over a standard tape measure?

The main advantage of a tenths tape measure is its enhanced precision. Measuring in tenths of an inch allows for more accurate and detailed measurements, which is crucial for projects requiring meticulous attention to detail. This level of precision reduces the likelihood of errors and ensures better quality results.

How do I properly maintain my tenths tape measure?

Proper maintenance involves regular cleaning, proper storage, careful handling, and frequent inspections. After each use, wipe the tape and casing with a dry cloth, and avoid submerging it in water. Store the tape measure in a cool, dry place using a protective case, and handle it gently to prevent damage. Regularly inspect the tape for wear and ensure the locking mechanism works correctly.

Can I use a tenths tape measure for all types of projects?

Yes, tenths tape measures are versatile and suitable for a wide range of projects, including construction, woodworking, metalworking, and tailoring. Their precise measurements make them ideal for tasks that require accuracy, while their durable construction ensures they can handle more demanding applications.

Are tenths tape measures more expensive than standard tape measures?

Generally, tenths tape measures can be slightly more expensive than standard tape measures due to their enhanced precision and additional features. However, the investment is often justified by the increased accuracy and durability, which can lead to better project outcomes and longer tool lifespan.

How do I ensure I am reading the tenths tape measure correctly?

To read a tenths tape measure correctly, familiarize yourself with the markings. Each inch is typically divided into tenths, with each division representing 0.1 inches. Ensure you are starting from the correct zero point and use the markings to get the precise measurement needed. Practice reading the tape to become more comfortable with the finer increments.

Final Thoughts

Final Thoughts

In conclusion, the tenths tape measure is an essential tool for anyone seeking accuracy and reliability in their measuring tasks. Its ability to provide precise measurements in tenths of an inch sets it apart from standard tape measures, making it invaluable for detailed projects and professional work. By understanding its features, applications, and maintenance requirements, you can maximize the benefits of using a tenths tape measure and achieve superior results in all your endeavors. Whether you’re constructing, crafting, or designing, investing in a high-quality tenths tape measure will undoubtedly enhance your efficiency and the quality of your projects.