Engineers Tape Measure: Understanding Its Features and Benefits

In the world of engineering and construction, precision is paramount. Whether you’re a professional engineer, a contractor, or a dedicated DIY enthusiast, having the right tools can make all the difference. One such essential tool is the engineers tape measure. Renowned for its accuracy, durability, and specialized features, an engineers tape measure is indispensable for a variety of tasks. This comprehensive guide will delve into the characteristics that set engineers tape measures apart, their various applications, tips for selecting the perfect tape measure, maintenance advice, and common pitfalls to avoid. By the end of this article, you’ll have a thorough understanding of why an engineers tape measure is a crucial addition to your toolkit.

What Sets an Engineers Tape Measure Apart?

What Sets an Engineers Tape Measure Apart?

An engineers tape measure is specifically designed to meet the rigorous demands of engineering projects. Unlike standard tape measures, engineers tape measures offer enhanced precision, durability, and functionality tailored to professional use.

Enhanced Precision and Accuracy

Engineers tape measures are engineered to provide precise measurements with minimal error. They often feature finer gradations, sometimes down to 1/64th of an inch, allowing for greater accuracy in complex projects. This level of precision is crucial when working on detailed engineering plans where even minor discrepancies can lead to significant issues.

Durable Construction

These tape measures are built to withstand the harsh conditions often encountered on construction sites or in engineering workshops. They typically feature reinforced edges, robust housings made from high-grade materials like stainless steel or durable plastics, and protective coatings to resist wear and tear. This durability ensures that the tape measure remains functional and reliable over extended periods of use.

Specialized Features

Engineers tape measures often come equipped with specialized features that enhance their functionality. These may include:

- Magnetic Hooks: Allowing for easier attachment to metal surfaces, facilitating hands-free measuring.

- Locking Mechanisms: Ensuring the tape stays in place once extended, providing stable measurements.

- Standout Marks: Indicating specific measurement points, which is particularly useful for repetitive tasks.

- Non-Reelable Tapes: Designed to be used in one direction to maintain accuracy without the tape winding back involuntarily.

Practical Applications

The versatility of an engineers tape measure makes it suitable for a wide range of applications across different fields. Here are some of the most common uses:

Engineering and Construction

In engineering and construction, precision is non-negotiable. Whether you’re drafting blueprints, building structures, or installing complex systems, accurate measurements are essential.

Blueprint Drafting

When creating blueprints, exact measurements are necessary to ensure that every component fits perfectly. An engineers tape measure provides the precision needed to transfer these measurements from paper to real-world applications.

Structural Building

Building frameworks, whether for residential homes or commercial buildings, requires meticulous measurement to ensure structural integrity. The durability and accuracy of an engineers tape measure make it ideal for marking and measuring materials accurately.

Manufacturing and Fabrication

In manufacturing, where parts must fit together seamlessly, an engineers tape measure ensures that each component meets the required specifications.

Machinery Assembly

Assembling machinery involves intricate measurements to ensure that each part aligns correctly. An engineers tape measure helps technicians measure and verify each component with high accuracy, reducing the likelihood of assembly errors.

Metalworking

Metalworking requires precise measurements for cutting, shaping, and assembling metal pieces. The enhanced precision of an engineers tape measure is crucial for maintaining the tight tolerances needed in metal fabrication.

DIY Projects and Home Improvement

Even in DIY projects, precision can elevate the quality of your work. An engineers tape measure can be a valuable tool for hobbyists and home improvement enthusiasts.

Cabinet Installation

Installing cabinets requires accurate measurements to ensure they fit perfectly within designated spaces. An engineers tape measure helps in marking precise positions for screws and supports, ensuring a professional finish.

Furniture Building

Building custom furniture involves intricate measurements for cutting and assembling parts. The accuracy of an engineers tape measure ensures that each piece fits together snugly, resulting in sturdy and aesthetically pleasing furniture.

Automotive and Aerospace

In industries like automotive and aerospace, where components must meet strict standards, an engineers tape measure plays a critical role.

Vehicle Customization

Customizing vehicles often involves modifying parts or adding new components. An engineers tape measure ensures that all modifications are measured accurately, maintaining the vehicle’s performance and safety.

Aerospace Engineering

Aerospace projects demand the highest levels of precision. An engineers tape measure helps engineers measure and verify components, ensuring they meet the stringent standards required in aerospace manufacturing.

Choosing the Right Engineers Tape Measure

Choosing the Right Engineers Tape Measure

Selecting the perfect engineers tape measure involves considering various factors to ensure it meets your specific needs. Here are key aspects to evaluate:

Length and Capacity

Engineers tape measures come in different lengths, typically ranging from 25 feet to 100 feet. The appropriate length depends on the nature of your projects:

- Shorter Lengths (25-33 feet): Ideal for indoor projects, tool workshops, and tasks requiring high precision.

- Medium Lengths (50-66 feet): Suitable for general construction, landscaping, and larger DIY projects.

- Longer Lengths (75-100 feet): Best for expansive projects like site surveying, large-scale construction, and outdoor applications.

Material and Durability

The material of the tape measure affects its durability and suitability for various environments:

- Stainless Steel: Highly resistant to rust and corrosion, making it ideal for outdoor use.

- Vinyl-Coated Tapes: Provide additional protection against moisture and physical damage.

- Fiberglass Reinforced: Adds strength and flexibility, perfect for demanding applications.

Accuracy and Markings

Precision is crucial when selecting an engineers tape measure:

- Fine Gradations: Look for tape measures with fine gradations, such as 1/64th of an inch, to ensure accurate measurements.

- Clear Markings: Ensure that the markings are easy to read, even in low-light conditions. High-contrast colors and engraved markings enhance visibility.

Specialized Features

Consider the additional features that can enhance the functionality of the tape measure:

- Magnetic Hooks: Facilitate hands-free measuring, especially on metal surfaces.

- Locking Mechanisms: Keep the tape extended securely, providing stable measurements.

- Standout Marks: Helpful for repetitive measurements and ensuring consistency.

- Non-Reelable Features: Prevent the tape from winding back involuntarily, maintaining accuracy during use.

Ergonomics and Comfort

A comfortable tape measure can reduce fatigue during extended use:

- Handle Design: Look for ergonomic handles that provide a comfortable grip.

- Weight: Ensure the tape measure is lightweight yet sturdy, balancing ease of use with durability.

Common Mistakes and How to Avoid Them

Even with the best tools, mistakes can happen. Here are some common errors when using an engineers tape measure and how to avoid them:

Misreading the Tape

Misreading the measurements can lead to significant errors in projects:

- Double-Check Measurements: Always verify your measurements by reading from different angles.

- Use Proper Lighting: Ensure adequate lighting to clearly see the tape markings.

- Mark Clearly: Use a pencil or marker to indicate measurement points, reducing reliance on memory.

Not Keeping the Tape Straight

Allowing the tape to bend or curve can result in inaccurate measurements:

- Use Helper Tools: Utilize tape measure hooks or magnetic features to keep the tape straight against surfaces.

- Hold Steady: Ensure both ends of the tape measure are held firmly to maintain a straight line.

- Avoid Twisting: Handle the tape measure carefully to prevent twisting, which can distort measurements.

Ignoring the Zero Point

Starting measurements from an incorrect zero point can throw off the entire project:

- Check the Zero: Ensure you are starting from the true zero mark, especially on metal tapes that may have an offset.

- Align Properly: When measuring from an edge, ensure the hook is correctly aligned with the starting point.

Relying Solely on the Tape

Over-reliance on the tape measure can lead to mistakes if not used correctly:

- Use Additional Tools: Complement the tape measure with other measuring tools like squares, levels, and calipers.

- Understand Scaling: Be aware of how scaling works on larger projects and adjust measurements accordingly.

Failure to Update or Replace

Using an outdated or damaged tape measure can compromise accuracy:

- Regularly Inspect: Continuously monitor the condition of your tape measure.

- Replace When Necessary: Do not hesitate to replace a tape measure that is showing signs of significant wear or inaccuracy.

Integrating Technology

Integrating Technology

Modern technology can enhance the functionality of your engineers tape measure, making measurements even more precise and efficient.

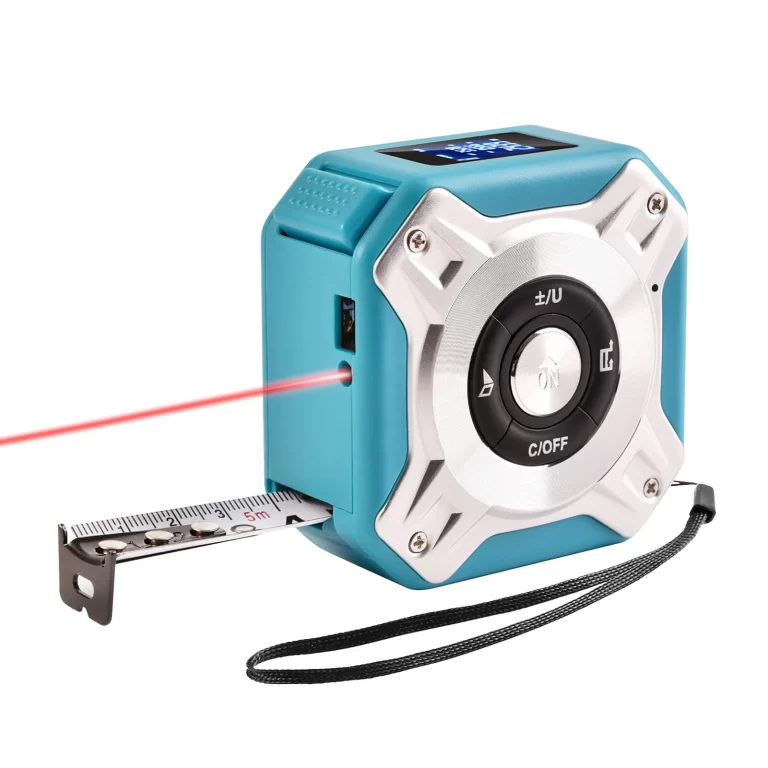

Digital Tape Measures

Digital tape measures integrate electronic displays, providing clear and exact measurements:

- Easy Reading: Digital displays eliminate the need to interpret fractional markings.

- Memory Functions: Store multiple measurements for easy reference during complex projects.

- Multiple Units: Switch between inches, centimeters, and other units with the push of a button.

Laser Measuring Tools

Laser measuring tools offer a high degree of accuracy for long distances:

- Quick Measurements: Instantly measure distances without the need for manual tape extension.

- Enhanced Precision: Laser tools reduce human error, providing more consistent measurements.

- Versatility: Suitable for both horizontal and vertical measurements, making them ideal for a variety of applications.

Smartphone Apps

Several smartphone apps can complement your tape measure by providing additional measuring features:

- Augmented Reality (AR): Use AR to visualize measurements directly on your project.

- Record-Keeping: Log measurements digitally for easy access and reference.

- Unit Conversion: Quickly convert measurements between different units without manual calculations.

Combining Traditional and Digital Tools

Integrating both traditional and digital measuring tools can offer the best of both worlds:

- Accuracy and Convenience: Use the tape measure for detailed, precise measurements and digital tools for efficiency and convenience.

- Redundancy: Having multiple measurement methods can provide a backup in case one tool fails or is unavailable.

Advanced Techniques for Using

For those seeking to elevate their measuring skills, advanced techniques can enhance the accuracy and efficiency of using an engineers tape measure.

Using a Laser Level

Combining a tape measure with a laser level ensures perfectly horizontal or vertical measurements:

- Alignment: Use the laser level to guide the tape measure, maintaining straight lines and accurate angles.

- Consistency: Ensure that all measurements are aligned with your laser level, preventing discrepancies across your project.

Implementing a Measurement Plan

Developing a structured measurement plan can streamline your workflow:

- Pre-Project Planning: Outline where measurements will be needed and plan your measuring route accordingly.

- Measurement Points: Identify critical points that require precise measurements and focus on accuracy in these areas.

- Documentation: Keep detailed records of all measurements to maintain consistency and reference throughout the project.

Precision Marking Techniques

Accurate marking is essential for precise measurements and cuts:

- Use Fine-Tip Tools: Utilize pencils or fine-tipped markers to make clear and precise marks.

- Mark at Eye Level: Ensure that marks are made directly under your sight line to reduce parallax errors.

- Double Marks: Make secondary marks to confirm measurement points before making cuts or adjustments.

Calibrating Your Tape Measure

Regular calibration ensures ongoing accuracy:

- Comparison Testing: Compare your tape measure against a known accurate standard regularly.

- Professional Calibration: Consider having your tape measure professionally calibrated to maintain precision.

- Adjustment Mechanisms: Some tape measures allow for minor adjustments to correct measurement discrepancies.

The Importance of Precision in Engineering Projects

The Importance of Precision in Engineering Projects

Precision in measurements, particularly with an engineers tape measure, is critical for the success and integrity of engineering projects. Here’s why:

Ensuring Structural Integrity

Accurate measurements ensure that all components fit together correctly, maintaining the structural integrity of the project. Inaccurate measurements can lead to weak joints, misaligned parts, and overall instability.

Enhancing Efficiency

Precision reduces the need for rework, saving time and resources. When measurements are accurate from the outset, projects progress smoothly without the delays caused by correcting mistakes.

Cost Savings

Minimizing errors through precise measurements can lead to significant cost savings. Reducing material waste and avoiding costly corrections can keep projects within budget.

Professional Quality

Accurate measurements contribute to the professional quality of the finished project. Whether it’s a building, machine, or any other engineering work, precision reflects the skill and attention to detail of the engineer or contractor.

Compliance with Standards

Engineering projects often need to comply with specific standards and regulations. Precise measurements ensure that all components meet these requirements, avoiding legal or safety issues.

Tools and Gadgets to Enhance Measurement Accuracy

Complementing your engineers tape measure with additional tools can further enhance accuracy and efficiency in your projects.

Measuring Squares

Measuring squares help maintain right angles and ensure that measurements are consistent:

- Right Angle Verification: Use measuring squares to confirm that corners and joints are perfectly perpendicular.

- Guided Measurement: Align the tape measure with the square to maintain straight lines and accurate measurements.

Marking Tools

Precise marking tools ensure that your measurements are clearly indicated:

- Pencils and Markers: Use fine-tipped pencils or markers to make clear and accurate marks based on your measurements.

- Chalk Lines: For longer measurements, chalk lines can help in marking straight and even lines across surfaces.

Levels and Plumb Bobs

Levels and plumb bobs ensure that your measurements are aligned correctly vertically and horizontally:

- Horizontal Measurements: Use levels to verify that horizontal measurements are straight and even.

- Vertical Alignments: Plumb bobs help in aligning measurements vertically, ensuring that structures are upright and true.

Calipers and Micrometers

For applications requiring extremely precise measurements, calipers and micrometers can complement your tape measure:

- Fine Measurements: Use calipers for measuring small dimensions with high accuracy.

- Thickness Gauging: Micrometers can measure the thickness of materials precisely, which is essential in metalworking and machining.

Conclusion

Conclusion

An engineers tape measure is more than just a measuring tool; it is an essential component of precision and efficiency in any engineering, construction, or DIY project. By offering enhanced accuracy, durability, and specialized features, engineers tape measures empower professionals and enthusiasts alike to achieve outstanding results with confidence. Whether you’re drafting blueprints, assembling machinery, renovating your home, or engaging in intricate DIY projects, the right tape measure can make all the difference. Embrace the precision and reliability that an engineers tape measure provides, and elevate the quality and success of your endeavors. Invest in a high-quality engineers tape measure today, and experience the transformative impact of precise measurement in every project you undertake.