Lines on a Tape Measure: A Guide for Accurate Measurements

A tape measure is a fundamental tool for anyone involved in construction, crafting, or home improvement projects. To utilize this tool effectively, understanding the lines on a tape measure is essential. This comprehensive guide will explore the different types of lines, their meanings, and how to leverage them for accurate measurements, ensuring your projects are executed flawlessly.

The Structure of a Tape Measure

The Structure of a Tape Measure

Before diving into the specifics of the lines, it’s important to grasp the overall structure of a tape measure. Typically, a tape measure consists of a retractable metal or fiberglass tape housed within a durable case. The tape itself is marked with a series of lines and numbers that represent different units of measurement, allowing users to measure lengths accurately.

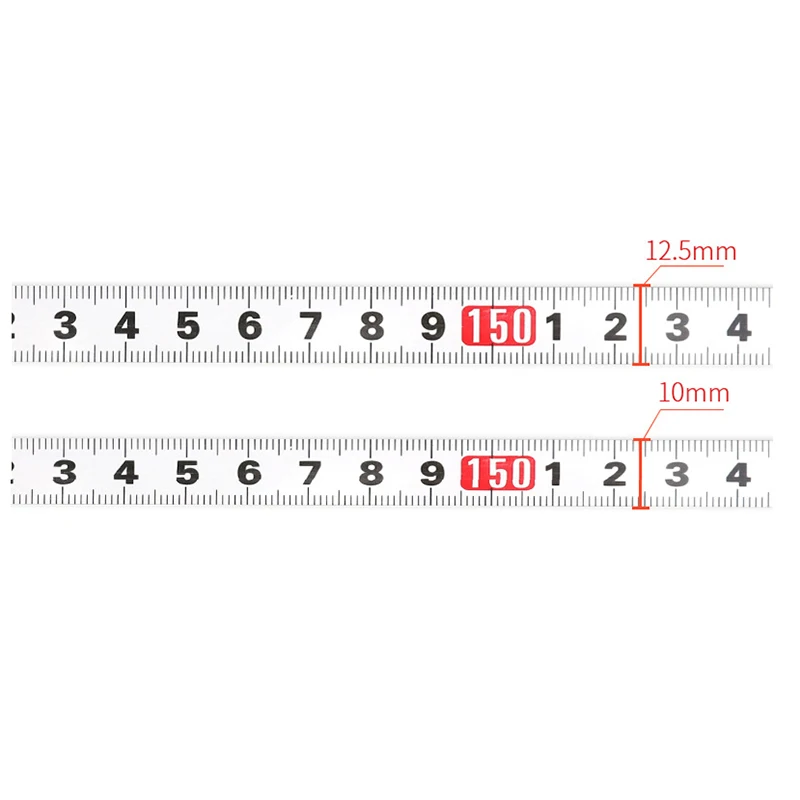

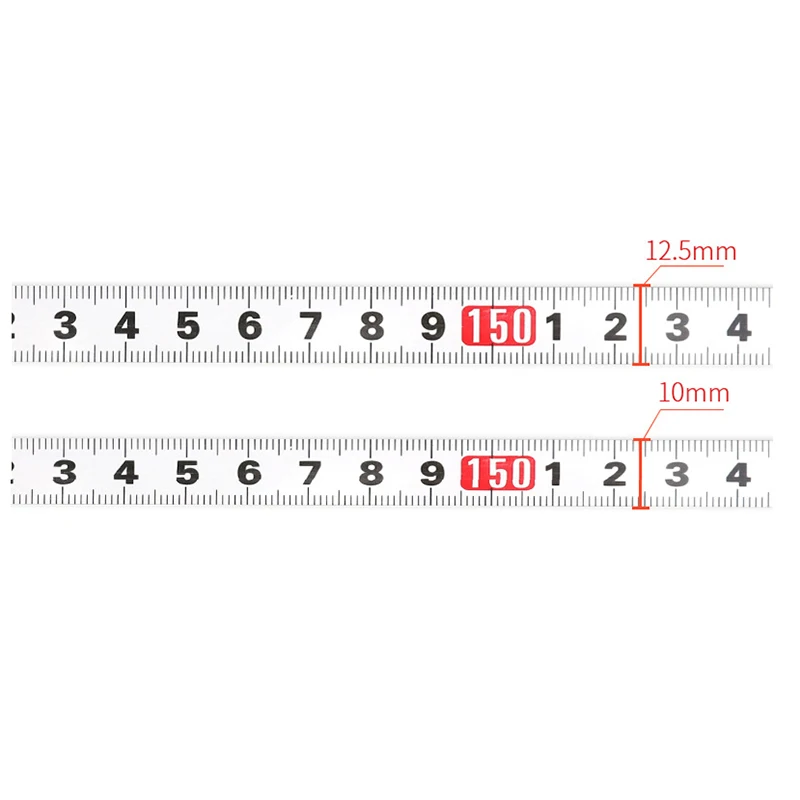

Major and Minor Lines

The tape measure features both major and minor lines. Major lines usually represent whole units, such as inches or centimeters, and are longer and more prominent. In contrast, minor lines indicate smaller increments between the major units, providing the precision needed for detailed measurements. Recognizing the difference between these lines is crucial for accurate measurement.

Unit Systems: Imperial vs. Metric

Tape measures come in different unit systems, primarily Imperial (inches and feet) and Metric (centimeters and millimeters). Most tape measures display both systems, allowing for versatility across various projects and personal preferences. Understanding how to read both systems can enhance your ability to measure accurately in different contexts.

Practical Applications of Tape Measure Lines

Understanding the lines on a tape measure is one thing, but applying that knowledge effectively is another. Here’s how you can use the lines on a tape measure in various scenarios to ensure accuracy and precision.

Construction and Carpentry

In construction and carpentry, precision is paramount. The various lines on a tape measure allow you to mark exact dimensions for cutting and assembling materials. For instance, when framing a wall, using the inch and half-inch lines ensures that each piece fits perfectly, maintaining structural integrity and aesthetic appeal.

DIY Projects and Home Improvement

Whether you’re building furniture, hanging shelves, or installing trim, the lines on a tape measure help you achieve neat and professional results. By following the quarter-inch or millimeter lines, you can make precise cuts and placements, ensuring that your DIY projects are both functional and visually appealing.

Sewing and Tailoring

For sewing and tailoring, the tape measure lines are essential for accurate fabric measurements. Using the half-inch and quarter-inch lines can help ensure garments are tailored to fit perfectly. Precise measurements prevent material waste and ensure that the final product meets the desired specifications.

Landscaping and Gardening

Even in landscaping and gardening, accurate measurements are important. Whether laying out a garden bed or installing a fence, the lines on a tape measure guide you in maintaining symmetry and balance. Using the appropriate lines ensures that your outdoor space is both beautiful and well-organized.

Tips for Using a Tape Measure Effectively

Tips for Using a Tape Measure Effectively

To maximize the utility of the lines on a tape measure, consider these practical tips:

Hold the Tape Measure Correctly

Proper handling of the tape measure ensures accurate readings. Always hold the tape measure flat against the surface you’re measuring and keep it taut to avoid any slack that could lead to errors. Familiarity with the tape’s structure helps maintain consistent measurements.

Read the Tape Measure at Eye Level

When taking a measurement, bring the tape measure to eye level to avoid parallax errors. This technique ensures that you read the lines accurately without any distortion caused by viewing angles. Consistent reading angles contribute significantly to measurement accuracy.

Use Both Hands for Stability

Using both hands to hold the tape measure provides additional stability, especially during longer measurements. One hand can anchor the tape at the starting point, while the other guides it to the endpoint, ensuring smooth and precise measurements. This method reduces the likelihood of the tape bending or sagging.

Mark Measurements Clearly

When making measurements, use a pencil or marker to clearly mark the desired points. This practice helps in transferring measurements accurately from the tape measure to the material, reducing the risk of mistakes during the cutting or assembly process. Clear markings are crucial for maintaining precision throughout the project.

Maintaining Your Tape Measure for Longevity

Proper maintenance can extend the life and performance of your tape measure. Here are some tips to keep your tape measure in top condition:

Keep It Clean and Dry

After each use, wipe down your tape measure to remove any dirt, dust, or moisture. Keeping the tape measure dry prevents rusting and maintains the visibility of the lines. Regular cleaning ensures that the tape measure remains reliable and accurate over time.

Avoid Overextending the Tape

Overextending the tape measure beyond its end can damage the casing and the tape itself. To prevent this, retract the tape gently and ensure it doesn’t bend or twist during use. Proper handling preserves the tape measure’s functionality and prevents costly repairs or replacements.

Store It Properly

Store your tape measure in a dry, safe place away from direct sunlight and extreme temperatures. Using a protective case or sheath can help preserve the tape measure’s condition and prevent wear and tear. Proper storage prolongs the lifespan of your tool, ensuring it remains in good working order.

Inspect Regularly

Regularly inspect your tape measure for any signs of damage or wear. Look for frayed edges, damaged lines, or a bent casing. Addressing these issues promptly can extend the lifespan of your tape measure and ensure it remains reliable. Regular inspections help identify and rectify problems before they escalate.

Advanced Uses for Tape Measure Lines

Beyond basic measurements, the lines on a tape measure can be used for various advanced applications. Here are some creative ways to utilize your tape measure:

Creating Templates and Guides

Use the lines to create precise templates or guides for cutting materials. This technique is particularly useful in woodworking, where accurate templates ensure pieces fit together seamlessly. Templates made using the tape measure lines help maintain consistency and accuracy across multiple cuts.

Measuring Angles and Heights

By combining measurements from different lines, you can calculate angles and heights for complex projects. This method is beneficial in carpentry and construction, where precise angles are crucial for stability and aesthetics. Calculating angles using tape measure lines enhances the accuracy of your measurements and the quality of your work.

Designing Patterns and Layouts

Artists and designers can use the tape measure lines to create symmetrical patterns and layouts. The consistent spacing of the lines aids in achieving balanced and harmonious designs. Incorporating tape measure lines into your creative process ensures precision in your artistic endeavors.

Crafting and Hobbies

In various crafting and hobby projects, the lines on a tape measure help maintain accurate dimensions. Whether building models, framing photos, or designing jewelry, precise measurements are key to high-quality results. Utilizing tape measure lines in crafting enhances the accuracy and professionalism of your projects.

Choosing the Right Tape Measure for Your Needs

Choosing the Right Tape Measure for Your Needs

Not all tape measures are created equal. Selecting the right tape measure depends on your specific needs and preferences. Consider the following factors when choosing a tape measure:

Length and Range

Tape measures come in various lengths, typically ranging from 12 feet to 100 feet. Choose a length that suits your project requirements. For home use and small projects, a 25-foot tape measure is often sufficient, while larger projects may require longer tapes. Selecting the appropriate length ensures you have the necessary range without excess bulk.

Material and Durability

The material of the tape measure affects its durability and ease of use. Steel tapes are robust and resistant to wear, making them suitable for heavy-duty applications. Fiberglass tapes are flexible and resistant to stretching, ideal for precise measurements. Choosing a durable material ensures your tape measure withstands frequent use and harsh conditions.

Locking Mechanism

A reliable locking mechanism ensures the tape stays in place when measuring. Look for tape measures with smooth and secure locks to prevent accidental retraction during use. A dependable locking mechanism enhances measurement stability and accuracy, making your work more efficient.

Ease of Reading

The clarity of the lines and markings is essential for accurate measurements. Choose a tape measure with clearly printed lines and numbers, preferably with color-coded markings for quick identification of different scales. Easy-to-read markings reduce the likelihood of errors and improve measurement precision.

Additional Features

Some tape measures come with extra features such as magnets, which help secure the tape to metal surfaces, or built-in levels for checking horizontal and vertical alignments. Consider these additional functionalities based on your specific needs. Extra features can enhance the versatility and convenience of your tape measure.

Common Mistakes to Avoid When Using a Tape Measure

Even with a clear understanding of the lines on a tape measure, certain mistakes can lead to inaccurate measurements. Here are some common pitfalls to watch out for:

Misaligning the Zero Mark

Always ensure that the zero mark of the tape measure aligns exactly with the starting point of your measurement. Misalignment can result in incorrect measurements, causing issues in the final assembly or installation. Proper alignment is crucial for maintaining measurement accuracy.

Reading at an Angle

Reading the tape measure from an angle can cause parallax errors, leading to inaccurate measurements. Always bring the tape measure to eye level to ensure a correct reading. Consistent reading angles help prevent distortion and enhance measurement precision.

Allowing the Tape to Bend

Keeping the tape measure straight and free from bends is crucial for accurate measurements. Bending the tape can distort the markings and lead to errors, especially during longer measurements. Maintaining a straight tape ensures that each line represents the true measurement.

Ignoring Wear and Tear

Worn or damaged lines can make it difficult to read the tape measure accurately. Regularly inspect your tape measure and replace it if the lines become unclear or the casing is damaged. Addressing wear and tear promptly helps maintain measurement reliability.

Relying Solely on Memory

After measuring, write down the measurement immediately instead of relying on memory. Forgetting the measurement can lead to mistakes, especially in complex projects with multiple measurements. Recording measurements ensures that you have accurate information throughout your project.

Enhancing Accuracy with Digital Tape Measures

Enhancing Accuracy with Digital Tape Measures

While traditional tape measures are effective, digital tape measures offer enhanced accuracy and additional features. Here’s how digital tape measures can complement your understanding of the lines on a tape measure:

Digital Readouts

Digital tape measures provide clear numeric readouts, eliminating the need to interpret lines manually. This feature reduces the risk of reading errors and speeds up the measuring process. Digital readouts offer a straightforward way to obtain accurate measurements quickly.

Multiple Measurement Units

Many digital tape measures allow you to switch between different units of measurement, such as inches, centimeters, and millimeters. This versatility is useful for projects requiring both metric and imperial measurements. Switching units easily enhances the flexibility of your measuring tool.

Memory Functions

Digital tape measures often come with memory functions that store multiple measurements, allowing you to recall them later without writing them down. This feature is particularly useful for complex projects with numerous measurements. Memory functions streamline the measurement process and reduce the need for constant note-taking.

Additional Tools

Some digital tape measures include features like built-in levels, laser pointers, and Bluetooth connectivity, enabling you to transfer measurements directly to digital devices for further processing. These additional tools enhance the functionality of your tape measure and integrate seamlessly with modern technology.

The Importance of Accurate Measurements

Accurate measurements are the foundation of any successful project. Whether you’re building, crafting, or installing, precise measurements ensure that all components fit together correctly and function as intended. Understanding the lines on a tape measure and using them effectively can save you time, reduce material waste, and enhance the overall quality of your work.

Preventing Material Waste

Inaccurate measurements can lead to excessive material waste, increasing project costs and resource consumption. By mastering the lines on a tape measure, you can plan and execute your projects more efficiently, minimizing waste and maximizing value. Efficient use of materials contributes to both cost savings and environmental sustainability.

Ensuring Structural Integrity

In construction and carpentry, accurate measurements are essential for ensuring the structural integrity of your work. Misaligned measurements can compromise the strength and stability of buildings, furniture, and other structures. Using the correct lines on a tape measure helps maintain accuracy, contributing to safe and reliable constructions.

Achieving Professional Results

Whether you’re a professional or a hobbyist, precise measurements contribute to professional-looking results. Neat, accurate cuts and proper alignments make your projects visually appealing and functionally sound, enhancing your reputation and satisfaction with your work. Professional results can lead to increased confidence and opportunities in your craftsmanship.

Conclusion

Conclusion

Understanding the lines on a tape measure is fundamental for achieving accurate and reliable measurements in any project. From the basic inch and millimeter lines to the finer fractional divisions, each line plays a crucial role in ensuring precision. By familiarizing yourself with the different lines, practicing proper measuring techniques, and avoiding common mistakes, you can elevate the quality of your work and achieve professional results every time.

Moreover, exploring advanced tools like digital tape measures can further enhance your measuring capabilities, offering greater accuracy and convenience. Whether you’re engaged in construction, crafting, sewing, or any other project, mastering the lines on a tape measure empowers you to execute tasks with confidence and precision. Embrace the knowledge of tape measure lines, and watch your projects come together seamlessly and successfully.