Spanner Wrench Usage Tips to Maximize Your Mechanical Repairs

Introduction

A spanner wrench is a versatile tool. Mechanics and plumbers often use it. It applies torque to turn objects. Spanner wrenches vary in shape and size. They fit different objects like bolts and pipe fittings. The term ‘spanner’ comes from its function. It ‘spans’ the distance across a nut or bolt head. The design of a spanner wrench provides leverage. This leverage helps to tighten or loosen fasteners. Each wrench type serves a specific purpose. It’s important to know the right one for the job. Spanner wrenches are common in tool kits. They handle a wide range of tasks. From home repairs to industrial maintenance, they are essential. Understanding how to use them is key. Proper use ensures tasks go smoothly and safely.

Types of Spanner Wrenches and Their Uses

Spanner wrenches come in several types. Each serves its unique purpose. Here are some common spanner wrenches and their applications:

- Open-end spanner: It has two open jaws. The jaws fit different sizes of nuts and bolts. It is useful for fast work.

- Ring spanner: This wrench has a ring end. The ring completely encircles the nut. It offers a better grip. It is good for tighter fastenings.

- Combination spanner: It combines open-end and ring features. One end is open, the other is a ring. It is versatile for various tasks.

- Adjustable spanner: Also known as a crescent wrench. It has a moving jaw. This adjusts to the size of the nut. It’s handy for different sized fittings.

- Socket spanner: It works with a ratchet handle. It is for bolts in deep or tight spaces. It is helpful for car repairs.

Each type of spanner wrench is crucial for specific tasks. Select the right one to make the job easier. For example, use a ring spanner for a firm grip. Choose an adjustable spanner for different sized nuts. Remember to match the wrench size to the fastener. This ensures a good fit and prevents damage. Knowing these types helps plan your work. It also prevents mistakes and injuries.

Selecting the Right Wrench for Your Task

Choosing the right spanner wrench is vital for your work. The wrench you pick must fit the fastener perfectly. Wrong selection can strip nuts or bolt heads. This results in damage and extra work. To avoid this, follow these steps:

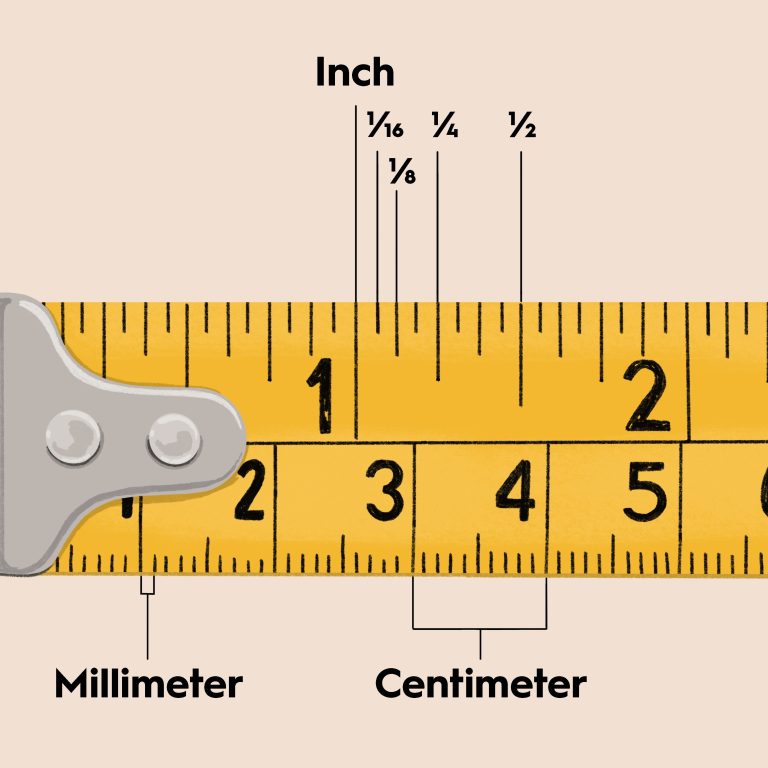

- Identify the Fastener Size: Measure or compare the fastener. Use a sizing chart if needed. This gives you the correct wrench size.

- Consider the Task’s Nature: Tight spaces need a socket spanner. Open spaces may allow for an adjustable spanner.

- Match the Wrench to the Fastener Type: Some fasteners need a ring spanner for full grip. Others work well with an open-end spanner.

- Think About the Strength Needed: Stubborn nuts require a wrench with more leverage. The ring end of a combination spanner is helpful here.

- Frequency of Task: If using one size often, pick a dedicated wrench. For varied sizes, an adjustable spanner may be best.

- Material of Fastener: Hardened fasteners may need a stronger wrench. Soft materials work fine with standard wrenches.

- Environmental Factors: In wet conditions, use a wrench with a non-slip grip. Protect against corrosion and slipping.

Remember to store your spanner wrenches well. Organize them by size for easy access. With the right spanner wrench, your task goes faster and safer. And you protect the fastener and tool from damage.

Safety Precautions When Using Wrenches

Safety Precautions When Using Wrenches

Using a spanner wrench safely is critical. Here are key safety tips:

- Wear Protective Gear: Always put on safety goggles. Protect your hands with gloves.

- Inspect the Wrench: Check your spanner wrench before use. Look for cracks or damage.

- Select the Right Size: Use a wrench that fits snugly. Loose wrenches can slip and cause injury.

- Avoid Overexertion: Don’t use excessive force. It could break the tool or fastener.

- Maintain a Good Grip: Keep your hands dry. Use non-slip gloves for a better hold.

- Use Proper Technique: Turn the wrench smoothly. Avoid jerky movements.

- Keep Your Workspace Tidy: Ensure the area is clear. This prevents tripping or dropping tools.

Following these tips can prevent accidents. It ensures a safer environment while working with spanner wrenches.

Step-by-Step Guide to Using a Wrench Properly

Using a spanner wrench with the right technique is crucial. Here is a simple guide to help you:

- Select the Correct Size: Make sure the spanner wrench matches the fastener’s size perfectly. It should fit snugly without any play.

- Position the Wrench Correctly: Align the wrench so that the handle extends along the line of the force you will apply. This gives better leverage.

- Apply Even Pressure: Turn the wrench smoothly and evenly. Sudden jerks can damage the tool or fastener.

- Pull, Don’t Push: Whenever possible, pull the wrench towards you. This helps maintain control and prevent injury if the wrench slips.

- Re-adjust When Necessary: After a complete turn, reposition the wrench for another grip if you can’t turn it further in that position.

- Do Not Over Tighten: Stop tightening as soon as the fastener is secure. Over-tightening can strip the threads or damage the fastener.

- Use Extensions Carefully: If you need more leverage, use a proper extension. Improvised or wrong extensions can lead to accidents.

- Finish with a Check: After you’ve completed your task, double-check the tightness of the fasteners to ensure everything is secure.

By following these steps, your work with a spanner wrench should be effective and safe. Keep your movements deliberate and controlled for the best results.

Maintenance and Care

Maintenance and Care

Proper maintenance is essential for keeping your spanner wrenches in top condition. Here are practical tips to help you care for your spanner wrenches:

- Clean After Use: Wipe your wrenches with a clean rag after each use. Remove dirt and oil to prevent rust.

- Check for Wear: Inspect your wrenches regularly. Look for signs of wear or damage. Replace them if needed.

- Lubricate Moving Parts: For adjustable wrenches, apply lubricant to the worm gear. This ensures smooth adjustment.

- Store Properly: Keep your wrenches in a dry place. Use a toolbox or wall rack to avoid moisture.

- Avoid Forceful Impact: Do not use your wrenches as hammers. It can cause damage to the wrench and the workpiece.

- Organize by Size: Arrange your wrenches according to size. This makes it easier to find the right one quickly.

Following these steps will prolong the life of your spanner wrenches. Regular care makes them more reliable and safe to use.

Troubleshooting Common Issues with Spanner Wrenches

Even with careful use, you might face issues with your spanner wrench. Knowing how to identify and fix common problems can save you time and hassle. Here are some troubleshooting tips for when you encounter difficulties with your spanner wrenches.

- Slipping from the Fastener: If your wrench keeps slipping, check its size. An incorrect fit is often the cause. Select the wrench that matches the fastener size to prevent slippage.

- Stuck Wrench: Sometimes a wrench might get stuck on a bolt. Apply penetrating oil to ease it off. Avoid using excess force which can cause damage.

- Rust and Corrosion: Rust can freeze your adjustable spanner’s moving parts. Regular cleaning and lubrication can prevent this. If rust occurs, use a rust remover and apply lubricant after cleaning.

- Damaged Wrench Jaws: Repeated use might wear out the jaws. Inspect them often. Replace the spanner wrench if the jaws are too worn to grip properly.

- Stripped Fasteners: A damaged fastener can be tough to turn. Use a nonslip grip or a different type of wrench. A bolt extractor might be necessary for severe cases.

- Loss of Torque: If the wrench isn’t turning effectively, check the handle for bends. A compromised wrench can reduce torque. In such cases, replacing the tool is the safest option.

By tackling these issues promptly, you’ll ensure your spanner wrench remains a reliable tool for your tasks.

Advanced Techniques and Tips for Professional Use

Advanced Techniques and Tips for Professional Use

Beyond the basics, professional spanner wrench users rely on advanced techniques. These ensure precision and efficiency in their work. Here are some expert tips that can elevate your spanner wrench skills:

- Use the Correct Motion: Always turn the wrench in a clockwise direction to tighten and counter-clockwise to loosen. This is a universal rule across all threading standards.

- Leverage for Tight Spaces: Use the box end of a combination spanner. It provides better leverage, especially in confined spaces.

- Double Wrench Technique: For added force, link two wrenches together. Place the box end of one wrench over the open end of another wrench for a makeshift longer handle.

- Offset Wrench Angles: Some spanner wrenches have a slight offset at the ring end. This angle helps navigate around obstructions.

- Torque Wrench for Precision: When accurate torque is essential, use a torque wrench. This is crucial for tasks like engine work where precise tightness is key.

- Stabilize the Spanner: For tasks where the fastener could be under tension, stabilize the spanner with your free hand while you turn it. This helps maintain control.

- Controlled Release: When loosening tight fasteners, apply slow and controlled pressure. Abrupt force can shear the fastener or cause injury.

- Knuckle Clearance: Ensure you have enough room for your knuckles to clear. Adjust your grip or wrench position to prevent injury.

Remember, the key to professional spanner wrench use is control and care. Hastily applied force is often the cause of injury and tool damage. With these advanced tips, you can tackle your tasks with confidence and professionalism.

Common Mistakes to Avoid

Even with the best tools, improper usage can lead to inefficiencies and potential hazards. Here are some common mistakes to avoid when using a spanner wrench to ensure safe and effective operations.

Using the Wrong Size

One of the most frequent errors is using a spanner wrench that doesn’t match the size of the fastener. This can cause slipping, rounding of the bolt or nut, and increased wear on both the tool and the fastener. Always verify the size before applying force.

Over-Tightening

Applying too much torque can strip the threads or break the fastener, compromising the integrity of your project. Use the appropriate amount of force and stop when the fastener is adequately tightened to prevent damage.

Ignoring Tool Condition

Using a damaged or worn-out spanner wrench can lead to ineffective torque application and potential accidents. Regularly inspect your tools for signs of wear, such as cracks, bent jaws, or loose handles, and replace them as needed.

Not Using Protective Gear

Failing to use protective gear, such as gloves, can result in hand injuries or reduced grip control. Always wear appropriate safety equipment to protect yourself and enhance your handling of the tool.

Poor Storage Practices

Improper storage can lead to tool damage and make it difficult to find the right wrench when needed. Store your spanner wrenches in an organized manner, ensuring they are protected from moisture and physical impacts.

Neglecting Maintenance

Skipping regular maintenance can reduce the lifespan and performance of your spanner wrenches. Make it a habit to clean, lubricate, and inspect your tools after each use to maintain their condition and functionality.

Innovative Uses of Wrenches: Beyond the Basics

Innovative Uses of Wrenches: Beyond the Basics

While spanner wrenches are traditionally used for tightening and loosening bolts and nuts, their versatility allows for a range of innovative applications. Here are some creative ways to utilize your spanner wrench beyond conventional tasks.

DIY Home Decor Projects

Spanner wrenches can be incorporated into DIY home decor projects, such as creating rustic shelf brackets or industrial-style light fixtures. Their sturdy construction and distinctive appearance add a unique touch to handmade crafts.

Artistic Sculptures

Artists often repurpose spanner wrenches in sculptures and installations, highlighting their industrial aesthetic and structural integrity. The tool’s form and functionality inspire creative designs and innovative art pieces.

Automotive Customization

In automotive customization, spanner wrenches are used not only for mechanical adjustments but also for customizing vehicle components. From modifying engine parts to adjusting suspension systems, their precision and strength are invaluable.

Bicycle Modifications

Cycling enthusiasts use spanner wrenches for fine-tuning and modifying their bicycles, ensuring optimal performance and comfort. Tasks such as adjusting the seat height, tightening handlebars, or installing accessories require the precision and control offered by spanner wrenches.

Small-Scale Construction

Spanner wrenches are essential in small-scale construction projects, such as building sheds, decks, or playground equipment. Their ability to handle multiple fasteners simultaneously speeds up assembly and ensures structural integrity.

Conclusion

Incorporating a spanner wrench into your toolkit is a strategic decision that can enhance your efficiency and effectiveness across a multitude of tasks. From understanding the different types and selecting the right one to mastering usage techniques and maintenance practices, this guide equips you with the knowledge needed to leverage the full potential of your spanner wrench. Investing in a high-quality spanner wrench not only simplifies your work but also ensures that you are prepared to tackle any fastening challenge with confidence and precision. Embrace the versatility and reliability of the spanner wrench, and watch as your projects become more manageable and your expertise grows.