Top Reasons to Choose a High-Quality Ratcheting Wrench Today

A ratcheting wrench is one of the most efficient and time-saving tools available for mechanical work. It combines the grip of a standard wrench with the convenience of a ratchet mechanism. This allows users to tighten or loosen fasteners without removing the tool after each turn.

As a result, it reduces effort and speeds up repairs significantly. Whether you’re working on a car, assembling furniture, or fixing household appliances, a ratcheting wrench makes the job smoother. Its ability to operate in tight spaces where full rotation isn’t possible gives it a major advantage over traditional wrenches.

What is a Ratcheting Wrench?

What is a Ratcheting Wrench?

A ratcheting wrench is a versatile hand tool. It tightens and loosens bolts and nuts. Unlike traditional wrenches, it has a ratcheting mechanism. This feature lets users turn fasteners without removing the wrench after each rotation. Ratcheting wrenches are ideal for tasks requiring speed and precision. They are widely used in automotive, mechanical, and household projects.

Key Features and Design

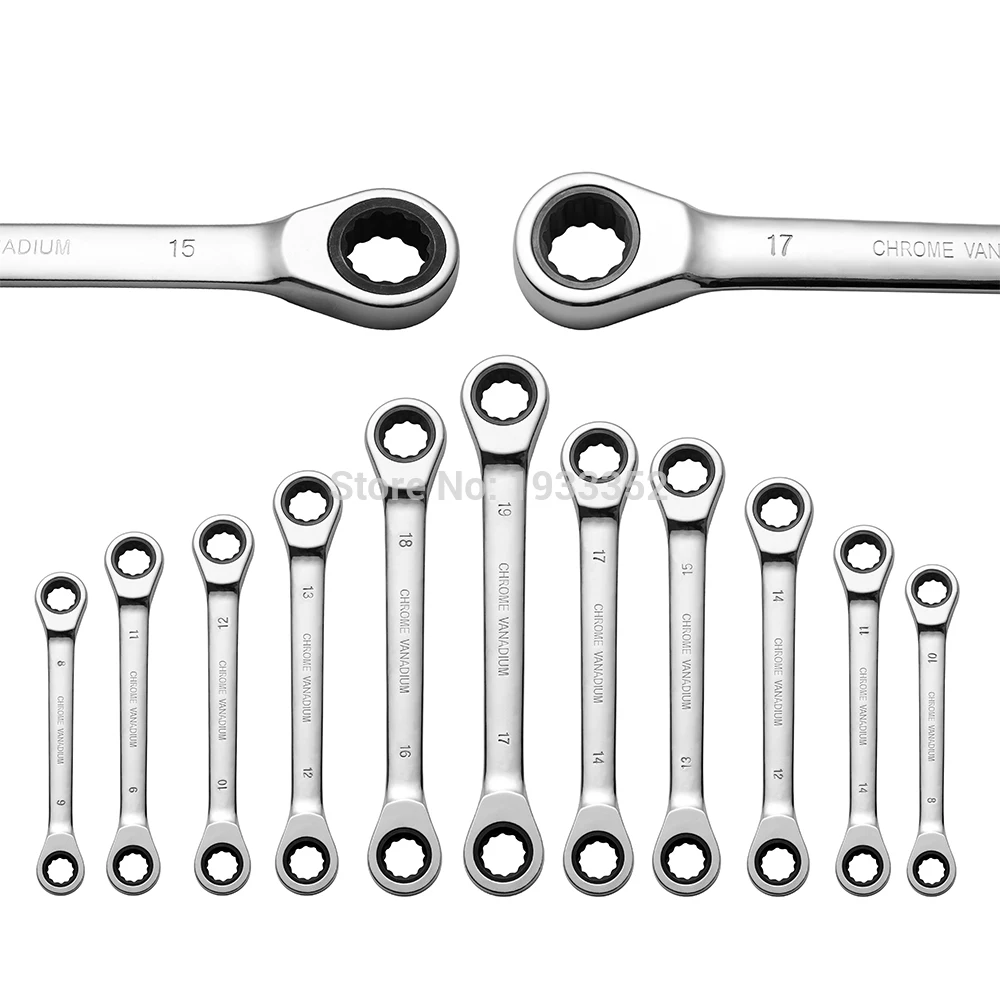

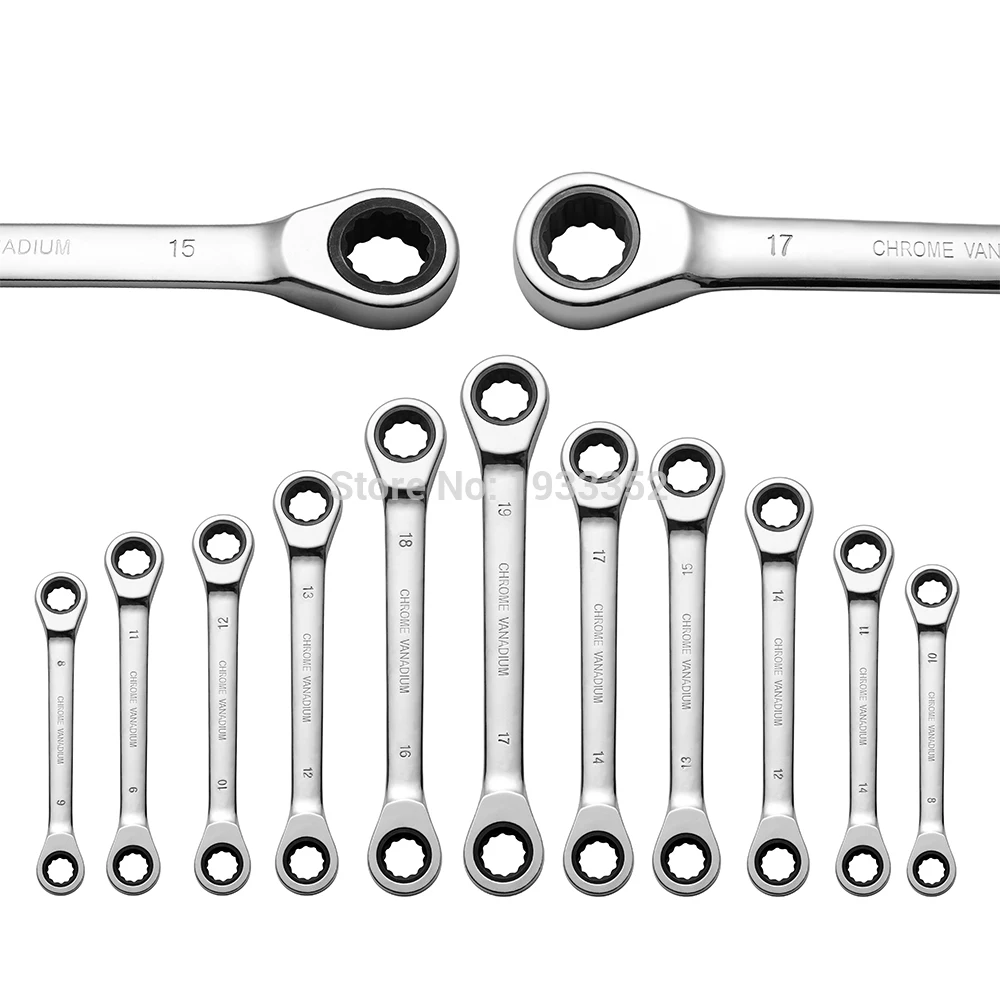

Ratcheting wrenches are designed for efficiency and ease of use. They often feature an enclosed ratchet mechanism in the wrench head. Some models have a reversible switch to change directions easily. This makes them useful for both tightening and loosening tasks. Additionally, they are crafted from durable materials like alloy steel or chrome vanadium to ensure long-lasting use.

Many ratcheting wrenches come with ergonomic handles for comfort during prolonged use. Some versions also offer flexible or pivoting heads. This allows access to bolts in tight or awkward spaces. The ratcheting teeth inside the tool can vary in number, affecting precision. More teeth mean smoother and more precise adjustments.

Types of Ratcheting Wrenches

Ratcheting wrenches come in multiple variations to suit different needs. The most common types include:

- Standard Ratcheting Wrench: These are straightforward tools suitable for general tasks. They have a fixed head and basic ratchet functionality.

- Flex-Head Ratcheting Wrench: This type features a flexible head that pivots. It makes handling jobs in confined or angled spaces much easier.

- Reversible Ratcheting Wrench: Equipped with a directional switch, this variant allows quick toggling between tightening and loosening functions.

- Combination Ratcheting Wrench: Designed with an open-end wrench on one side and a ratcheting box-end on the other. It combines the benefits of two tools in one.

- Ratcheting Wrench Sets: Typically sold as sets, these contain multiple sizes to cater to a wide range of fasteners. Sets offer convenience for tackling diverse projects.

Understanding the features and variants can help pick the right ratcheting wrench for your tasks.

The Mechanics Behind the Tool

Directional Control and Lever Movement

Most ratcheting wrenches include a small switch on the head. You can flip it to change from tightening to loosening mode. This control is smooth and accessible with one hand.

The number of teeth in the gear determines how small the swing arc can be. High-tooth-count ratchets need only a few degrees of movement. This is crucial in cramped areas under dashboards or inside machinery.

Manufacturers measure this as “degrees per click.” Some wrenches offer 3°, others up to 10°. Fewer degrees mean faster progress in confined spaces.

The handle design also matters. It should allow a firm grip without slipping. Ergonomic shapes reduce hand fatigue during long jobs.

With each back-and-forth motion, the ratcheting wrench maintains contact and delivers consistent torque.

This efficiency saves time and reduces frustration during repairs.

Benefits

Ratcheting wrenches offer distinct advantages over traditional wrenches. They are designed to improve efficiency, precision, and ease of use. These tools help complete tasks faster and with less effort. Their versatility makes them ideal for various applications.

Enhanced Efficiency and Speed

The ratcheting mechanism saves time during operations. You can tighten or loosen bolts without lifting the wrench repeatedly. This feature is helpful for tasks that involve numerous fasteners. The design reduces hand strain by minimizing repetitive movements. Additionally, fine ratcheting teeth allow for smoother and quicker adjustments. This makes it easier to work in demanding conditions, delivering faster results.

Ease of Use in Tight Spaces

Ratcheting wrenches are perfect for confined or hard-to-reach areas. Their compact design allows access where regular wrenches fail. Flex-head versions enhance versatility by pivoting to reach angled spaces. Ergonomic handles add comfort during prolonged use in cramped environments. These features simplify repairs and installations, especially in automotive and mechanical projects.

How to Choose the Right Wrench

How to Choose the Right Wrench

Selecting the right ratcheting wrench is crucial for efficiency and durability. Various factors come into play when making a choice. A careful consideration of these ensures that the tool meets your specific needs.

Consider Material and Durability

Material quality determines the longevity of a ratcheting wrench. Opt for tools made from hardened alloy steel or chrome vanadium. These materials resist wear, corrosion, and frequent usage. Chrome plating adds extra protection and aesthetic appeal. A durable tool can handle demanding tasks without breaking or deforming. Make durability your priority, especially for professional-grade tools.

Importance of Size and Fit

Choosing the correct size ensures proper fastening. Ratcheting wrenches come in metric, SAE, or dual measurements. Ensure the set matches the standard sizes of your bolts or nuts. Using the wrong size can damage fasteners or reduce efficiency. Sets with multiple sizes offer versatility, making them a better investment. Always double-check compatibility before purchasing to avoid inconvenience.

Popular Brands and Models

Reputable brands ensure reliability and high performance. Brands like GearWrench, Craftsman, and DEWALT are industry leaders. GearWrench offers innovative flex-head designs for versatility. Craftsman provides durable wrenches with a lifetime warranty. DEWALT focuses on robust, professional-use tools that withstand wear. Always read reviews or ask for recommendations to find the best brand for your needs.

How to Properly Use a Ratcheting Wrench

Using a ratcheting wrench correctly ensures efficiency, safety, and better precision. Follow the steps and tips below to make the most out of this essential tool.

Step-by-Step Instructions

- Select the Right Wrench Size: Choose the size that matches the nut or bolt.

- Position the Wrench: Place the wrench securely on the fastener, ensuring it fits snugly.

- Set the Direction: Use the reversible switch if available. Set it to tighten or loosen.

- Rotate the Handle: Move the handle back and forth without lifting the wrench.

- Finish Tightening or Loosening: Repeat the motion until the fastener is fully secure or removed.

- Check the Fastener: Ensure the bolt is properly tightened or loosened before moving to the next task.

Tips for Avoiding Common Mistakes

- Avoid Over-Tightening: Excess force can damage fasteners or the wrench.

- Keep Ratcheting Teeth Clean: Dirt can reduce the tool’s effectiveness.

- Inspect for Damage: Regularly check the wrench for cracks or wear.

- Use Proper Technique: Don’t twist the wrench at odd angles as this may cause injury.

- Choose Quality Tools: Low-grade wrenches may fail under high pressure or frequent use.

By carefully following instructions and avoiding mistakes, you can maximize the life and utility of your ratcheting wrench.

Maintenance and Care

Proper maintenance ensures the durability and performance of your ratcheting wrench. Regular care prevents malfunctions and extends the tool’s lifespan. Below are essential practices to maintain the efficiency of your wrench.

Cleaning and Lubrication

- Clean After Every Use: Wipe your ratcheting wrench with a clean cloth to remove dirt or grease.

- Inspect the Ratchet Mechanism: Check for debris inside the ratcheting teeth. Dirt can hinder smooth operation.

- Use a Brush for Deep Cleaning: Use a small brush to clean hard-to-reach areas of the wrench.

- Lubricate the Ratchet Mechanism: Apply a few drops of lubricant to ensure smooth rotations and prevent rust.

- Remove Excess Oil: After lubricating, wipe off excess oil to avoid attracting dust and grime.

- Avoid Harsh Chemicals: Steer clear of chemical cleaners that may damage the tool’s coating.

Routine cleaning and lubrication improve the tool’s performance, making your tasks more efficient.

Proper Storage Techniques

- Store in a Dry Area: Keep the wrench in a moisture-free environment to prevent rust or corrosion.

- Use a Tool Organizer: Place wrenches in a designated organizer to protect them from physical damage.

- Avoid Stacking: Don’t stack heavy tools on the wrench to avoid bending or breaking.

- Keep Away From Extreme Temperatures: Store away from excessive heat or cold, which can weaken the material.

- Utilize Protective Cases: Use cases or pouches for added protection during storage or transportation.

- Inspect Before Storing: Always check the wrench for damage after use and before storing it.

By following these tips, you can protect your ratcheting wrench and ensure reliable performance over time.

Common Applications

Common Applications

Ratcheting wrenches are a must-have for a variety of tasks. Their versatility makes them ideal for automotive, household, and professional uses. Below are the key areas where these tools excel.

Automotive Repairs

Ratcheting wrenches simplify common car repair tasks. They are perfect for tightening and loosening bolts in narrow spaces. Mechanics often use flex-head ratcheting wrenches to access hard-to-reach areas under the hood. These tools save time during complex repairs, like engine work or brake maintenance. Their precision ensures bolts are secured or removed without damaging threads. Reversible models help switch between tightening and loosening quickly.

Household Tasks

Ratcheting wrenches are convenient for fixing furniture or appliances at home. They work well for assembling furniture, where bolts need quick tightening. DIY enthusiasts also use them for plumbing jobs, like tightening pipe fittings. Their compact design allows access to bolts in compact spaces, such as under sinks. These tools are light and easy to handle, making them beginner-friendly for household use.

Professional Use Cases

Professionals rely on ratcheting wrenches for demanding industrial and mechanical tasks. In construction, they fasten bolts on structures and scaffolding efficiently. Electricians use them to handle bolts and screws in confined electrical cabinets. Additionally, ratcheting wrenches are valuable for aerospace and manufacturing tasks requiring extreme precision. Sets with varied sizes help professionals handle diverse fastener types easily.

Understanding these applications highlights the importance of investing in a high-quality ratcheting wrench.

Comparing Ratcheting Wrenches to Traditional Wrenches

Comparing Ratcheting Wrenches to Traditional Wrenches

Ratcheting wrenches and traditional wrenches both serve the purpose of tightening and loosening fasteners. However, they differ significantly in design, functionality, and ease of use. Understanding these differences helps users choose the right tool for specific tasks.

Advantages Over Regular Wrenches

- Speed and Efficiency: Ratcheting wrenches save time by eliminating the need to reposition the tool repeatedly. Their mechanism allows continuous fastening or loosening with minimal effort.

- Precision: Fine ratcheting teeth provide smooth adjustments, ensuring accurate fastening work. This improves results in detail-oriented tasks.

- Ease in Tight Spaces: Compact designs and flex-head options enable access to confined areas. Regular wrenches often fail in such situations.

- Reduced Strain: Ergonomic handles and ratcheting mechanisms minimize hand strain during prolonged use.

- Versatility: Ratcheting wrenches come in various types, such as flex-head and combination models. Each type offers specific advantages, enhancing usability across applications.

Situations Where Traditional Wrenches Are Better

- Heavier Torque Requirements: Traditional wrenches are often stronger, allowing more force without damaging the tool.

- Simpler Design: Their straightforward design makes them less prone to mechanical wear over time.

- Cost-Effective: Traditional wrenches are usually more affordable, making them ideal for basic tasks.

- Heavy-Duty Tasks: For industrial or construction work, traditional wrenches can handle extreme conditions better.

- Fewer Moving Parts: With no ratcheting mechanism, traditional wrenches are simpler to maintain and repair.

Both tools have unique strengths, catering to different needs. Choose based on task complexity and environmental conditions.

Frequently Asked Questions

Can a ratcheting wrench replace a socket wrench? In many cases, yes. But sockets offer more reach and torque for deep fasteners.

Is it safe to use on stripped bolts? Not recommended. Use a locking plier or extractor first.

Do all ratcheting wrenches have reversible direction? Yes. A switch on the head changes between tighten and loosen.

Can I use it with regular sockets? Only if it has a socket drive end. Most fixed wrenches do not.

How do I clean the inside mechanism? Use compressed air to blow out debris. Then apply a drop of oil.

Are cheaper wrenches worth it? For occasional use, yes. But they wear faster under heavy loads.

Can it damage bolts? Only if improperly used. Always match the wrench size to the fastener.

Is it useful for beginners? Absolutely. It simplifies repairs and reduces effort.

Final Thoughts

Final Thoughts

A ratcheting wrench is more than just a tool—it’s a time-saving, effort-reducing powerhouse. From home projects to professional repairs, it delivers consistent performance.

Its smart design, durability, and adaptability make it essential in any toolkit. Whether you’re a weekend DIYer or a full-time mechanic, owning a quality ratcheting wrench improves your work.

In conclusion, if you’ve ever struggled with tight spaces or repetitive motions, the ratcheting wrench is your solution. So invest in one today—and experience how this simple tool transforms the way you fix, build, and maintain.