Top Features to Look for in the Best Crescent Wrench Today

The crescent wrench is a staple in toolboxes around the world. Known for its adjustable jaw, this hand tool fits a wide range of bolt and nut sizes. Its design allows quick changes without needing multiple fixed wrenches. As a result, the crescent wrench is a favorite among mechanics, plumbers, and DIYers.

Moreover, the name “crescent wrench” comes from the Crescent Tool Company. They invented the modern adjustable wrench in the early 20th century. Even though other brands make similar tools, many people still use “crescent wrench” as a general term.

In addition, this tool features a smooth jaw and a knurled screw mechanism. You turn the knob to open or close the movable jaw. This lets you grip fasteners of various dimensions. It is especially useful when working in tight spaces where socket sets won’t fit.

Furthermore, the crescent wrench comes in many sizes. Small ones fit in a pocket. Large models handle industrial jobs. Each size serves a specific purpose.

They are made from chrome vanadium steel. This material resists rust and wear. It also withstands high torque without bending.

Therefore, whether you’re fixing a leaky pipe or assembling furniture, the crescent wrench proves its value. It’s not just convenient. It’s essential.

How a Crescent Wrench Works

How a Crescent Wrench Works

A crescent wrench operates using a simple yet effective mechanism. At one end, there is a fixed jaw. It stays in place and provides a solid base. The other side has a movable jaw. This part slides along a threaded screw.

You control the jaw size with a thumb screw. Turn it clockwise to tighten. Rotate it counterclockwise to open the jaw wider. This adjustment happens quickly. You can resize it in seconds.

The jaw opens at an angle. This angled design improves grip. It also allows access from different directions. You don’t always need to remove the wrench to reposition.

When you apply force, the pressure pushes the movable jaw tighter. This keeps the wrench from slipping. It grips more securely under load.

Most models have a smooth face on one jaw. The other may have teeth. These teeth prevent slippage on rounded bolts.

The handle is long. This increases leverage. You can apply more torque with less effort.

Some models include measurement markings. These show the jaw width in inches or millimeters. This helps you set it precisely.

Always pull the wrench toward you. This keeps your hand behind the joint. It reduces the risk of injury if it slips.

As a result, the crescent wrench combines ease of use with strong performance.

Common Uses

The crescent wrench is incredibly versatile. One of its main uses is in plumbing. Plumbers use it to tighten or loosen pipe fittings. It works on compression nuts and supply lines.

In automotive repair, it fits where sockets can’t. You can reach tight engine bolts. It helps with brake lines, hose clamps, and brackets.

Homeowners use it for everyday fixes. It’s perfect for assembling furniture. You can tighten loose bolts on chairs or shelves.

It also works on bikes. Adjust the pedals, handlebars, or seat post. The adjustable jaw adapts to different bolt sizes.

HVAC technicians rely on it too. They use it on ductwork and refrigerant lines. The compact design fits in crowded utility spaces.

Electricians sometimes use it. They tighten conduit fittings or mounting hardware. However, they avoid using it on live circuits.

In manufacturing, it serves for quick adjustments. Machines often need small tweaks. The crescent wrench allows fast action.

Camping and emergency kits include a small version. It’s lightweight and multi-functional.

Even artists and sculptors use it. They assemble metal frames or secure joints.

As a result, the crescent wrench appears in nearly every trade. Its usefulness spans industries and hobbies.

Types of Wrenches

Types of Wrenches

Several types of crescent wrenches exist. The standard model is the most common. It has an adjustable jaw and a flat handle.

Mini crescent wrenches are smaller. They fit in tool pouches. These are ideal for electronics or jewelry repair.

Offset crescent wrenches have a bent head. This design improves access in confined areas. You can turn bolts behind walls or panels.

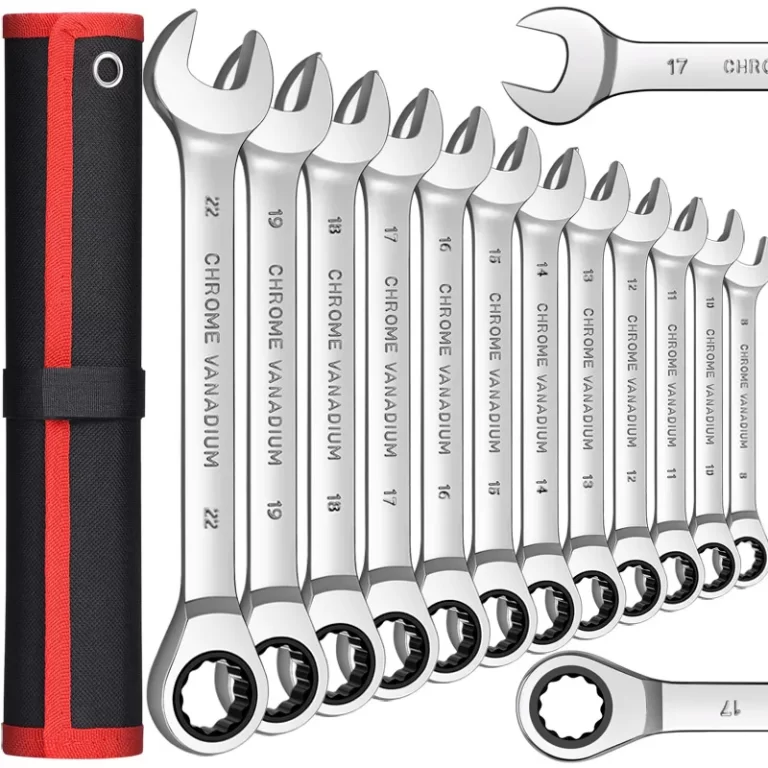

Ratcheting crescent wrenches are newer. They combine adjustment with a ratcheting mechanism. You don’t need to lift the tool after each turn.

Some models have a locking feature. Turn the knob to lock the jaw in place. This prevents accidental movement during use.

Combination wrenches include a fixed end. One side is adjustable. The other has a fixed opening.

Long-handle versions offer more torque. They are used in heavy-duty applications. These are common in industrial settings.

Insulated crescent wrenches are made for electrical work. They have rubber coating. This protects against electric shock.

Some are magnetic. The jaw holds onto bolts. This helps in awkward positions.

Each type serves a specific need. Choose based on your task and workspace.

Materials and Build Quality

Crescent wrenches are typically made from chrome vanadium steel. This alloy is strong and durable. It resists breaking under pressure.

The surface is often chrome-plated. This prevents rust and makes cleaning easy. It also reduces friction.

High-quality models have precise machining. The threads on the adjustment screw are smooth. They don’t bind or strip easily.

The knurled knob should be easy to turn. It must stay in place under torque. Cheap models may loosen during use.

Jaws must stay parallel. Misaligned jaws slip off nuts. This can damage the fastener or hurt the user.

Heat treatment strengthens the metal. It increases hardness. This prevents jaw deformation.

Ergonomic handles improve comfort. Some have rubber grips. These reduce hand fatigue.

Brands like Crescent, GearWrench, and Stanley lead in quality. They offer lifetime warranties.

Avoid soft or lightweight models. They may bend or strip. Always check for brand markings.

Good build quality ensures long-term reliability.

How to Choose the Right Wrench

How to Choose the Right Wrench

Choosing the right crescent wrench starts with size. Measure the fasteners you’ll work on. Common sizes range from 6 to 12 inches.

A 6-inch model fits small jobs. It’s good for home use. A 10-inch or 12-inch handle gives more leverage.

Consider your workspace. In tight areas, a shorter or offset wrench works better. For heavy tasks, go larger.

Look at the adjustment mechanism. Smooth, precise movement matters. Test it if possible.

Check the jaw finish. Smooth jaws protect soft metals. Toothed jaws grip better on stubborn bolts.

Ergonomics are important. The handle should fit your hand. It must not slip when greasy.

Some models have built-in measurement scales. These help set the jaw quickly. They save time and improve accuracy.

Brand reputation matters. Stick to trusted names. They use better materials and design.

Price is a factor. Don’t go too cheap. A low-cost wrench may fail when you need it most.

Finally, think about extras. Does it have a ratchet? Is it insulated? These features add value.

Safety Tips

Safety is key when using a crescent wrench. Always pull, never push. Pulling gives you better control. It keeps your hand away from sharp edges.

Make sure the jaw fits snugly. A loose fit can slip. This may damage the nut or cause injury.

Turn the wrench toward the fixed jaw. This keeps force on the strongest part. It reduces the chance of breakage.

Avoid using pipes or extensions. These increase torque. They can bend or break the wrench.

Inspect the tool before use. Look for cracks or worn threads. Replace damaged tools immediately.

Keep the wrench clean. Dirt and grease reduce grip. Wipe it after each use.

Store it properly. Hang it or keep it in a toolbox. Don’t toss it in a pile with other tools.

Wear safety glasses. Metal chips or debris can fly off.

Don’t use it on rounded bolts. Use a socket or extractor instead.

Never strike the wrench with a hammer. It is not designed for impact.

Following these rules keeps you safe and the tool intact.

How to Maintain Your Wrench

How to Maintain Your Wrench

Proper maintenance extends the life of your crescent wrench. First, clean it after use. Wipe off oil, dirt, and moisture.

Use a dry cloth. For stubborn grime, use a mild solvent. Avoid strong chemicals.

Lubricate the screw mechanism occasionally. A drop of light oil keeps it moving smoothly. Wipe off excess.

Check the jaw alignment. If it wobbles, the threads may be damaged. Replace or repair it.

Tighten the pivot screw if needed. Some models have an access point. Use a small tool to adjust it.

Store in a dry place. Humidity causes rust. Use a tool cabinet or drawer.

Avoid dropping it. Impacts can bend the jaw or break the handle.

Sharpen the teeth if they wear down. Use a small file. Do this carefully to keep the shape.

Inspect regularly. Look for cracks, bends, or corrosion.

Well-maintained tools perform better. They last longer and stay safe.

Frequently Asked Questions

Can I use a crescent wrench on all bolt types?

Mostly yes. It works on hex, square, and some rounded bolts. Avoid using it on stripped fasteners.

Is a crescent wrench the same as an adjustable wrench?

Yes. “Crescent” is a brand name. But it’s often used to describe any adjustable wrench.

Can it replace a socket set?

Not completely. It’s less precise. But it’s great for quick fixes and tight spaces.

Why does my wrench keep slipping?

The jaw may be too loose. Or the bolt is rounded. Set the jaw tightly and squarely.

Are chrome wrenches better than black ones?

Chrome resists rust better. Black oxide finishes may wear faster.

Can I use it on plumbing fittings?

Yes. It’s ideal for nuts on water lines and valves.

Do insulated crescent wrenches work on live circuits?

Only if rated for it. Check the voltage rating. Always follow electrical safety rules.

How do I know the jaw size?

Some models have markings. Otherwise, measure the opening with a ruler.

Summary

Summary

The crescent wrench remains one of the most useful tools in any kit. Its adjustable jaw, strong build, and wide range of applications make it indispensable. From home repairs to industrial jobs, it delivers performance and convenience.

Whether you’re a professional or a beginner, owning a quality crescent wrench is wise. It saves time, reduces the number of tools needed, and handles unexpected tasks.

With proper use and care, it will last for years. Always choose a trusted brand. Maintain it regularly. Follow safety practices.

As long as bolts and nuts exist, the crescent wrench will have a place. For anyone asking, “Is the crescent wrench still relevant?”—the answer is a clear yes. The crescent wrench is here to stay.