Top Reasons Mechanics Still Trust the Beam Torque Wrench

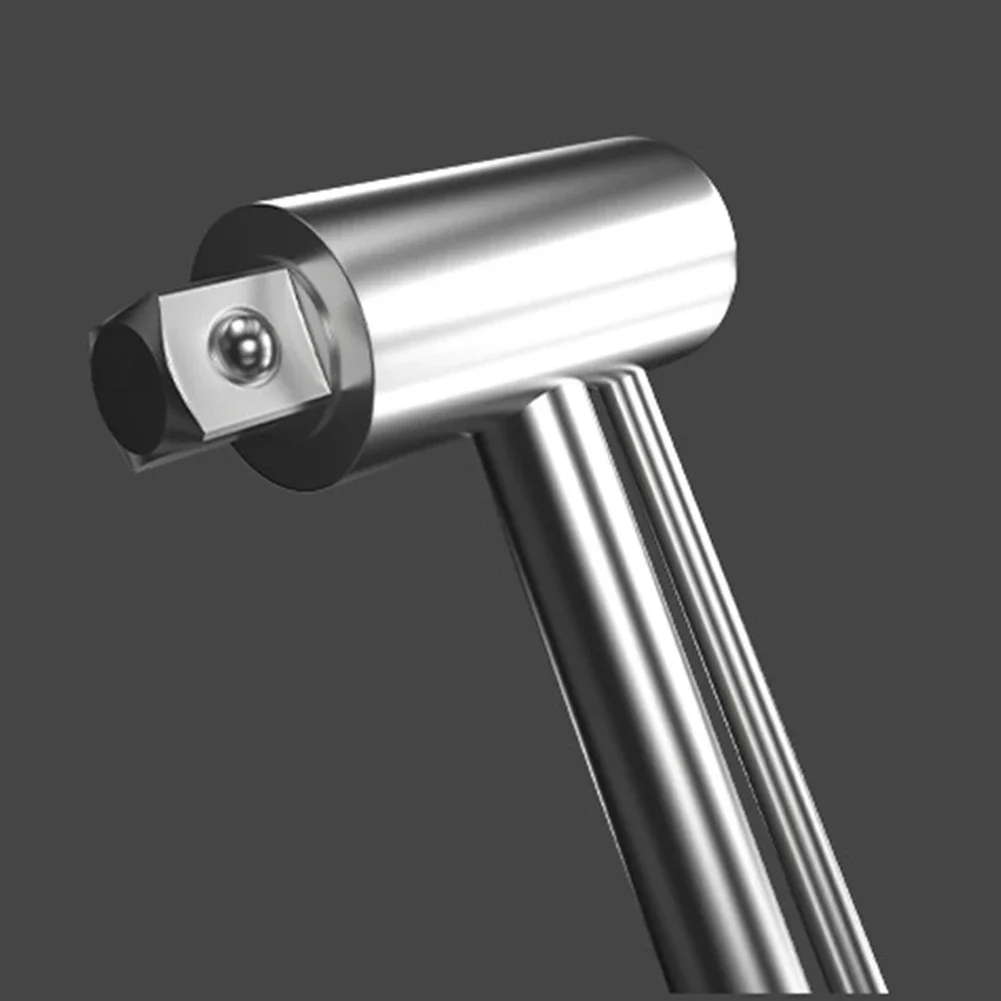

What is a Beam Wrench?

A beam torque wrench is a simple and reliable tool for tightening fasteners. It measures torque by using a flexible steel beam and a pointer. The beam bends when force is applied to the wrench handle. This causes the pointer to move along a scale, showing how much torque is being applied.

Unlike other torque wrenches, a beam torque wrench does not require calibration frequently. Its design ensures consistent accuracy when used correctly. It works without complex internal mechanisms or batteries, making it durable and easy to maintain.

Beam torque wrenches are primarily used in automotive, plumbing, and machinery repair tasks. Users often prefer them for their visual feedback and affordability. This tool is a smart choice when both accuracy and budget are priorities.

Key Features of a Beam Wrench

Key Features of a Beam Wrench

Beam torque wrenches are popular due to their simplicity and reliability. They come with several standout features that make them a preferred choice for various applications.

- Durable Design: Made of flexible steel, the beam ensures long-term functionality without frequent issues.

- No Calibration: Unlike many other torque wrenches, they rarely need recalibration, saving time and costs.

- Accurate Measurement: Their visual torque display reduces errors, enhancing precision during tightening.

- Easy-to-Read Scale: The scale is clear and straightforward, enabling quick and accurate torque readings.

- Battery-Free Operation: Beam torque wrenches do not require batteries or electronics, reducing maintenance.

- Affordable: These tools are budget-friendly compared to advanced torque wrench models.

- Versatile Application: Beam torque wrenches are suitable for automotive repairs, plumbing, and machinery maintenance tasks.

These key features make beam torque wrenches highly effective for professionals and hobbyists alike. Understanding these characteristics will help you choose the right tool for your specific needs.

Advantages of Using a Beam Wrench

Beam torque wrenches offer several advantages that make them a preferred choice for professionals and DIY enthusiasts. Their design and functionality cater to accuracy, durability, and affordability. Here are the key advantages:

- Exceptional Accuracy: The visual pointer on the beam allows precise tracking of applied torque. This minimizes the risk of errors during fastener tightening.

- Durability: Made of flexible steel, beam torque wrenches are resilient. They withstand regular use without frequent wear or damage.

- Low Maintenance: Unlike other torque wrenches, beam models rarely need recalibration. This saves users time and money.

- Cost-Effective: Beam torque wrenches have a simple mechanism, making them more affordable than advanced electronic models.

- Battery-Free Operation: Since they work mechanically, beam torque wrenches require no batteries. This eliminates dependency on power sources and reduces overall maintenance.

- Ease of Use: These wrenches have clear, easy-to-read scales. Anyone can operate them without needing special training.

- Reliable Performance: The straightforward design ensures consistent accuracy and reliability during repeated tasks.

- Versatility: Suitable for automotive repairs, plumbing work, and machinery maintenance, beam torque wrenches adapt to various tasks.

By understanding these advantages, users can make confident choices for their projects. A beam torque wrench combines functionality and affordability, making it a practical tool for professionals and hobbyists alike.

Step-by-Step Guide to Using a Beam Wrench

Step-by-Step Guide to Using a Beam Wrench

Using a beam torque wrench correctly is essential for accuracy and safety. Follow these steps to ensure proper operation.

Preparing the Wrench and Workspace

- Inspect the Wrench: Check for any signs of damage or wear on the wrench.

- Clean the Fastener: Remove debris or rust from the fastener for a good grip.

- Secure the Workspace: Make sure the area is stable and well-lit.

- Select the Right Wrench: Confirm the wrench matches the required torque range.

Aligning the Pointer with Zero

- Hold the Wrench Upright: Ensure the beam and pointer are in the correct position.

- Check the Scale: Verify that the pointer aligns precisely at the zero mark.

- Adjust if Necessary: If misaligned, gently reposition the pointer to zero.

Applying Torque to the Fastener

- Position the Wrench: Attach the wrench securely to the fastener.

- Grip the Handle: Hold the handle firmly to apply force effectively.

- Apply Steady Force: Move the handle smoothly to avoid sudden jerks.

Monitoring the Beam and Scale

- Watch the Pointer: Observe the pointer as you apply torque.

- Stop at Desired Torque: Stop applying force once the pointer hits the targeted torque value.

- Double-Check Accuracy: Verify the reading to ensure precision.

By following these instructions, you can use a beam torque wrench effectively. Proper operation enhances accuracy, safety, and the lifespan of your tool.

Common Applications of Beam Wrenches

Beam torque wrenches are versatile tools used in various fields. Their simplicity and accuracy make them a go-to choice for many industries. Here are the most common applications:

Automotive Maintenance

- Engine Repairs: Beam torque wrenches help tighten bolts and nuts with precise force.

- Wheel Lugs: They ensure wheel lugs are tightened to the recommended torque values.

- Suspension Work: These wrenches prevent over-tightening, protecting components from damage.

Plumbing Projects

- Pipe Fittings: Beam torque wrenches tighten pipe joints to avoid leaks and ensure a proper seal.

- Valve Installation: Their accuracy prevents overtightened valves, ensuring smooth operation.

Machinery Assembly and Maintenance

- Assembly Lines: They provide consistent torque for assembling machinery components, ensuring reliability.

- Routine Maintenance: Beam torque wrenches are used to check and adjust fasteners in industrial machines.

DIY and Hobbies

- Bicycle Repairs: Cyclists use these tools to adjust parts like handlebars and seat posts.

- Woodwork Joints: They offer precision when securing screws and bolts in woodworking projects.

Aerospace and Aviation

- Aircraft Assembly: Torque precision is crucial for safety, making these wrenches essential in aviation.

- Component Repairs: They are used in maintaining aircraft parts, ensuring proper torque specifications.

Agricultural Equipment

- Farm Machinery: Beam torque wrenches help maintain equipment like tractors to minimize wear.

- Irrigation Systems: These tools ensure secure connections in irrigation setups to prevent leaks.

Beam torque wrenches adapt to various needs, ensuring safety and reliability in all applications.

Tips for Accurate and Safe Torque Application

Tips for Accurate and Safe Torque Application

Accurately and safely applying torque using a beam torque wrench is crucial. Small mistakes can lead to damaged fasteners, inefficient tightening, or even safety risks. Following these tips ensures optimal performance:

Always Work in a Stable Environment

- Keep your workspace flat, clean, and clutter-free.

- Ensure proper lighting for clear visibility of the pointer and scale.

- Avoid distractions while tightening fasteners for accurate application.

Inspect the Wrench Regularly

- Check the pointer and beam for any signs of damage.

- Make sure the scale is legible and clean.

- Replace the wrench if you notice bent or warped parts.

Use the Correct Torque Settings

- Refer to fastener specifications to determine the required torque value.

- Match the wrench’s range with your project needs.

- Ensure bolts and nuts are in good condition before tightening.

Apply Force Smoothly

- Hold the wrench handle firmly and apply consistent pressure.

- Avoid jerking or rapid movements to maintain precision.

- Stop applying force as soon as the pointer reaches the desired torque mark.

Monitor the Pointer and Scale Closely

- Focus on the scale as you tighten the fastener.

- Ensure the pointer stops exactly at the target value.

- Double-check readings, especially in critical applications.

Avoid Over-Tightening

- Be mindful of stopping at the recommended torque value.

- Over-tightening can damage threads or compromise joint integrity.

- If unsure, consult user manuals or experts.

Store and Maintain Properly

- Clean the wrench after each use to prevent dirt buildup.

- Store in a dry and safe place to avoid environmental damage.

- Periodically inspect and adjust the pointer alignment.

By implementing these tips, you guarantee precise torque application and extended tool life. Always prioritize accuracy and safety during use to prevent errors and damage.

Maintaining and Storing Your Beam Wrench

Proper maintenance and storage of your beam torque wrench ensure its long-lasting and reliable performance. Neglecting these aspects can lead to reduced accuracy and a shorter lifespan. Follow these simple but effective practices.

Cleaning Your Beam Torque Wrench

- Wipe After Each Use: Use a clean cloth to remove dirt, grease, and debris.

- Inspect for Damage: Check for bent parts or loose screws after every use.

- Avoid Harsh Chemicals: Use mild cleaners to prevent damaging the scale.

- Dry Thoroughly: Ensure no moisture remains before storing to avoid rust.

Proper Storage Practices

- Use a Protective Case: Store the wrench in its case to shield it from dust and moisture.

- Choose a Dry Location: Ensure the storage space is free from humidity.

- Avoid Direct Sunlight: Keep the wrench away from prolonged sunlight exposure to protect the scale markings.

- Store Upright: Position the wrench vertically to prevent the beam from bending.

Periodic Inspections

- Check the Pointer Alignment: Ensure the pointer stays aligned with the zero mark.

- Look for Rust: Address any rust immediately with rust remover or special tools.

- Inspect the Scale: Ensure the torque scale remains readable and intact.

- Test Functionality Regularly: Periodically use the wrench to make sure it operates correctly.

Handling Precautions

- Avoid Dropping: Prevent accidental impacts as they can bend the beam or misalign the pointer.

- Use for Its Purpose Only: Do not misuse it as a regular tool, preventing undue wear.

- Do Not Exceed Limits: Avoid applying torque beyond the wrench’s maximum capacity.

Longevity Tips

- Lubricate Moving Parts: Use appropriate lubricants to ensure smooth operation.

- Replace Damaged Components Promptly: Use manufacturer-approved replacements for accuracy.

- Store Separate from Heavy Tools: Prevent heavy items from bending or damaging the wrench.

By following these maintenance and storage tips, you can prolong your beam torque wrench’s utility and effectiveness. A well-maintained tool ensures accurate torque application and safe operation across countless projects.

Troubleshooting Common Issues

Troubleshooting Common Issues

Beam torque wrenches are simple tools, but issues can arise during usage. By identifying and addressing these problems, you can maintain the tool’s performance and extend its lifespan.

Pointer Misalignment

- Cause: Dropping the wrench or applying excessive force can misalign the pointer.

- Solution: Gently realign the pointer using a screwdriver or your fingers.

- Prevention: Avoid dropping the tool and store it properly in a protective case.

Difficulty Reading the Scale

- Cause: Dirt, scratches, or faded markings can make the scale hard to read.

- Solution: Clean the scale with a soft cloth and check for scratches.

- Prevention: Keep the wrench clean and avoid exposing it to harsh chemicals.

Rust Formation

- Cause: Storing the wrench in damp or humid conditions can lead to rust.

- Solution: Remove rust using a specialized rust remover or steel wool.

- Prevention: Store the tool in a dry place and use a protective case.

Beam Bending or Damage

- Cause: Overloading the wrench beyond its torque capacity can bend the beam.

- Solution: Replace the bent beam with a new one from the manufacturer.

- Prevention: Ensure torque levels do not exceed the wrench’s capacity during use.

Loose Fasteners

- Cause: Applying inconsistent force can lead to improperly tightened fasteners.

- Solution: Reapply torque using steady and controlled force.

- Prevention: Follow user guides and avoid jerky movements.

Erratic Pointer Movement

- Cause: Dirt, grease, or loose components can affect the pointer’s movement.

- Solution: Clean the wrench, tighten loose screws, and check for damage.

- Prevention: Clean the tool regularly and inspect it before every use.

Torque Values Not Matching

- Cause: Incorrect pointer calibration leads to inaccurate torque readings.

- Solution: Reset the pointer to align with the zero on the scale.

- Prevention: Regularly check pointer alignment before starting any task.

Wrench Handle Issues

- Cause: Worn-out grips or broken handles reduce effectiveness.

- Solution: Replace the handle or grips as needed.

- Prevention: Use the wrench carefully and avoid overstressing it.

Scale Wear and Tear

- Cause: Frequent use can fade or scratch the scale over time.

- Solution: Contact the manufacturer for replacement parts.

- Prevention: Handle the wrench delicately and clean the scale properly.

By addressing these common issues early, you can keep your beam torque wrench functioning efficiently. Proper use, maintenance, and storage help avoid these problems and ensure precise torque application.

Frequently Asked Questions

Is a beam torque wrench accurate?

Yes. It’s one of the most accurate types. No preset mechanism means no drift.

Do I need to calibrate it?

Rarely. It maintains accuracy unless damaged.

Can I use it for left-handed threads?

Yes. Torque direction doesn’t affect the reading.

Is it suitable for beginners?

Yes. Easy to understand and use.

What units does it measure in?

Most show ft-lb and Nm. Some include in-lb.

How do I know my torque setting?

Read the scale directly. No preset needed.

Are beam wrenches waterproof?

They resist moisture. But prolonged exposure harms metal.

Can I use extensions with it?

Yes. But they change leverage. Recalculate torque accordingly.

Final Thoughts

Final Thoughts

Every mechanic knows that precision saves time, money, and lives. The beam torque wrench stands out as a timeless tool that combines simplicity, durability, and unmatched accuracy. Whether you’re building an engine, repairing machinery, or maintaining aircraft, this device ensures every bolt is tightened exactly as required.

Its design has changed little over decades because it works flawlessly. No batteries, no clicks, no guesswork—just a clear visual indication of applied force. That’s why so many professionals still choose a beam torque wrench over newer alternatives.

Moreover, its low maintenance and resistance to misuse make it ideal for both shops and fieldwork. When reliability is non-negotiable, nothing beats the proven performance of this classic tool.

So if you’re equipping your garage or upgrading your toolkit, remember the fundamentals. Because in the world of precision mechanics, knowing how to use a beam torque wrench can make all the difference. And yes, owning a beam torque wrench is not just smart—it’s essential.