Top Features to Look for in a Durable Adjustable Spanner Wrench

When it comes to versatility and reliability in hand tools, few items match the practicality of an adjustable spanner wrench. This essential tool allows users to grip and turn fasteners of various sizes without needing a full set of fixed wrenches. Whether you’re fixing a leaky faucet, assembling furniture, or working on car repairs, the adjustable spanner wrench delivers consistent performance across countless tasks. Its ability to adapt to different bolt and nut dimensions makes it a favorite among DIYers, mechanics, and professional tradespeople alike.

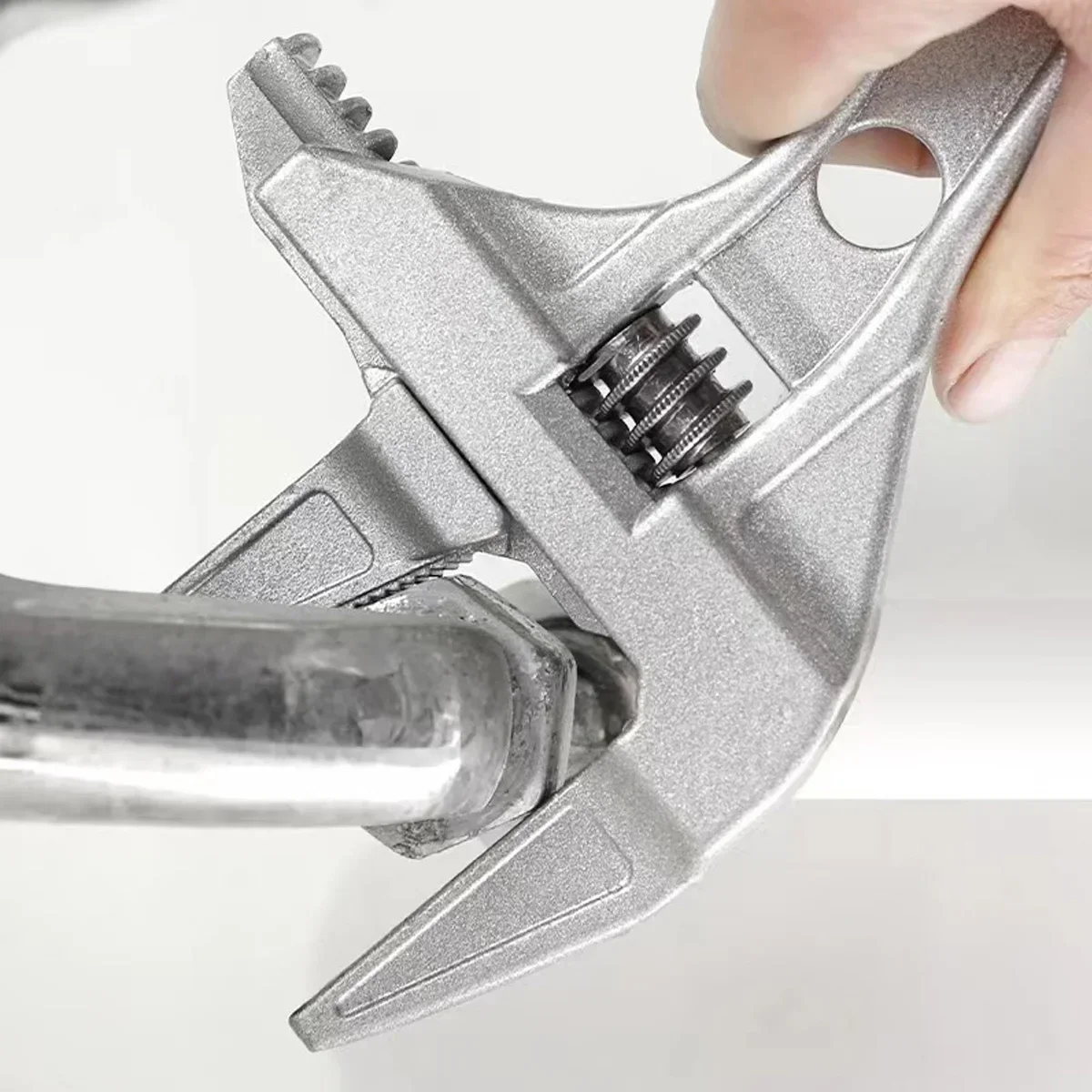

Moreover, the adjustable spanner wrench stands out because it saves both space and money. Instead of carrying ten different wrenches, you can rely on one well-built adjustable model. Also, its simple mechanism—featuring a movable jaw controlled by a worm gear screw—ensures quick size adjustments with just a twist of the thumb wheel. As a result, switching between jobs becomes faster and more efficient.

Additionally, modern versions of the adjustable spanner wrench come with improved materials and ergonomic designs. Many feature chrome-plated jaws for corrosion resistance, laser-etched size markings for accuracy, and cushioned grips for comfort. These upgrades enhance durability and reduce hand fatigue during prolonged use. Therefore, today’s models are far superior to older, basic versions.

What is an Adjustable Spanner Wrench?

What is an Adjustable Spanner Wrench?

An adjustable spanner wrench is a versatile hand tool for tightening or loosening fasteners. It features a movable jaw, allowing it to fit various bolt and nut sizes. This adaptability makes it a must-have for DIY projects and professional toolkits.

Features and Design

The adjustable spanner wrench is defined by its simple but effective design. It has:

- Adjustable Jaw: The movable jaw adapts to different fastener sizes with a screw mechanism.

- Handle: A long, sturdy handle provides leverage and grip.

- Measurement Scale: Some models include size markings for precise adjustments.

- Durable Build: Made of materials like steel for strength and reliability.

The jaw opens and closes smoothly, making size adjustment efficient. Its ergonomic design reduces hand fatigue.

Common Applications

An adjustable spanner wrench is highly adaptable for various tasks. Common uses include:

- Plumbing: Tightening or loosening pipes and fixtures.

- Automotive Repairs: Working with vehicle fasteners of various sizes.

- Home Maintenance: Fixing or assembling furniture and appliances.

- General Construction: Securing bolts and nuts in carpentry or metalwork.

It is a reliable tool across industries due to its flexibility. With proper use, it ensures efficient and stable fastening.

How to Properly Adjust the Wrench

Adjusting the jaw of an adjustable spanner wrench ensures precision during use. Proper adjustment protects fasteners and enhances efficiency. Adopt careful techniques to avoid slippage or poor grip.

Identifying the Correct Jaw Size

Identifying the correct jaw size is the first step for a secure fit. Follow these tips:

- Inspect the Fastener: Observe the bolt or nut’s size carefully.

- Open the Jaw Gradually: Adjust the movable jaw to a size slightly larger than the fastener.

- Slide Onto the Fastener: Place the wrench on the bolt or nut. Ensure a snug fit without force.

Correct size selection helps prevent tool damage and reduces the risk of slipping.

Steps to Adjust the Jaw

Adjusting the jaw is simple but requires focus. Use these steps for proper adjustment:

- Locate the Adjustment Screw: The screw mechanism controls the jaw’s movement.

- Turn the Screw Clockwise: For a tighter fit, rotate the screw until the jaw matches the fastener.

- Turn Counterclockwise: To widen the jaw, rotate the screw the other direction.

- Test the Fit: After adjustment, check if the wrench grips the fastener securely.

Consistency in adjustment improves tool accuracy and makes fastening easier.

Tips for Safe and Efficient Use

Tips for Safe and Efficient Use

Proper use of an adjustable spanner wrench ensures safety and improves efficiency. Following key practices can reduce risks and enhance results.

Preventing Slippage and Damage

Slippage and damage can be avoided with proper precautions. Here’s how:

- Choose the Right Jaw Size: Ensure the jaw matches the size of the fastener.

- Snug Fit is Critical: Adjust the jaw to grip the fastener securely, avoiding loose fits.

- Avoid Excess Force: Apply consistent pressure to prevent over-tightening or slipping.

- Check for Wear: Regularly inspect the wrench for any damage or wear.

Preventing slippage protects fasteners and tools while ensuring more stable connections.

Proper Grip and Handling Techniques

Correct handling improves performance and reduces strain. Follow these tips:

- Hold Firmly: Maintain a tight grip on the handle during use.

- Use Both Hands (if needed): For added control, use your other hand to support the wrench.

- Apply Steady Pressure: Gradually turn the wrench without abrupt jerks.

- Position the Wrench Properly: Align it correctly with the fastener to avoid awkward angles.

Efficient handling minimizes user fatigue and improves overall precision during tasks.

Maintenance and Care

Proper maintenance maximizes the lifespan of your adjustable spanner wrench. Regular upkeep ensures smooth operation and reliable performance.

Cleaning the Wrench

Dirt and grime can affect the wrench’s efficiency. Clean it regularly to keep it in optimal condition.

- Wipe Down After Use: Use a dry cloth to remove dirt and debris.

- Use Mild Cleaner: For heavy grime, apply a mild soap solution and scrub gently with a brush.

- Dry Thoroughly: Ensure the wrench is completely dry to prevent rust.

- Inspect for Residue: Check the jaw and screw mechanism for any leftover dirt.

Frequent cleaning keeps the wrench functional and prevents build-up that could hinder adjustments.

Lubricating Moving Parts

Lubrication ensures smooth jaw movement and protects metal parts from wear.

- Select the Right Lubricant: Use oil or silicone-based lubricants made for tools.

- Apply Sparingly: Add a few drops to the adjustment screw and moving jaw.

- Work the Mechanism: Turn the screw to spread the lubricant evenly.

- Wipe Excess Oil: Remove any extra lubricant to avoid attracting dust.

Periodic lubrication enhances the wrench’s performance and reduces the risk of jamming.

Storing the Wrench to Avoid Wear

Proper storage protects your adjustable spanner wrench from damage.

- Choose a Dry Location: Store in a place free from moisture to prevent rust.

- Use a Tool Organizer: Keep it in a toolbox or designated storage area to avoid damage.

- Avoid Heavy Loads: Do not store heavy items on top of the wrench to prevent deformation.

- Protect the Jaw: Ensure the jaw is partially closed to maintain its shape.

Thoughtful storage safeguards your wrench and ensures it’s ready for use at any time.

Common Mistakes to Avoid When Using an Adjustable Spanner

Common Mistakes to Avoid When Using an Adjustable Spanner

Knowing the common mistakes can help you use an adjustable spanner wrench effectively. Avoiding these errors ensures long-lasting performance and reduces the risk of injury or damage.

Over-tightening the Jaw

Over-tightening is a frequent mistake when using an adjustable spanner wrench. Here’s why you should avoid it:

- Risk of Damage: Excess pressure on the fastener can strip threads or deform the nut or bolt.

- Tool Wear: Over-tightening puts stress on the wrench, leading to faster wear.

- Slippage: A too-tight jaw may fail to grip properly, causing the wrench to slip.

To avoid over-tightening:

- Adjust the jaw to fit snugly, but not excessively tight.

- Apply consistent pressure without forcing the wrench excessively.

- Test the fit before applying full torque to the fastener.

Proper use increases both tool and fastener longevity.

Using on Damaged Nuts and Bolts

Using an adjustable spanner wrench on damaged fasteners can lead to ineffective results. Common issues include:

- Poor Grip: Damaged nuts or bolts often have rounded edges, reducing grip.

- Increased Slippage: The wrench may slip off, causing hand injury or fastener damage.

- Tool Damage: Repeated use on damaged fasteners can shorten the wrench’s lifespan.

Prevent these issues by:

- Inspecting fasteners for damage before using the wrench.

- Using specialized tools like locking pliers for rounded fasteners.

- Replacing severely damaged nuts or bolts instead of forcing the wrench.

Correct judgment extends the life of your tools and ensures safer tasks.

Alternatives to Spanner Wrenches

While adjustable spanner wrenches are versatile, there are other tools worth considering for specific tasks. Choosing the right tool can increase efficiency and reduce damage risks.

Comparison with Fixed Wrenches

Fixed wrenches, also known as open-end or box-end wrenches, differ significantly from adjustable spanners. Here’s how they compare:

- Precision Fit: Fixed wrenches are designed for specific nut or bolt sizes. This ensures a perfect fit.

- Strength: They offer more durability because they lack moving parts.

- Ease of Use: Fixed wrenches don’t require size adjustments, saving time during repetitive tasks.

- Limited Versatility: Unlike adjustable spanners, fixed wrenches cannot accommodate varying fastener sizes.

In summary, fixed wrenches are ideal for tasks that involve repetitive fastening of the same size.

Specialized Tools for Specific Jobs

Certain tools can handle tasks better than adjustable spanner wrenches. Here are some alternatives:

- Pipe Wrenches: Perfect for gripping and turning pipes. Their serrated jaws provide extra hold.

- Socket Wrenches: Allow easier access to recessed or hard-to-reach fasteners. They are excellent for automotive tasks.

- Pliers: Useful for gripping irregularly shaped objects or damaged fasteners.

- Torque Wrenches: Ideal for applications requiring precise torque settings, like assembling machinery.

- Ring Spanners: Offer a full-circle grip around fasteners for more stability and less slippage.

Each alternative is suited for specialized tasks, offering more efficiency in certain situations. By understanding these alternatives, you can select the best tool for your project.

Frequently Asked Questions

Frequently Asked Questions

Can an Adjustable Spanner Replace Multiple Tools?

An adjustable spanner wrench can replace several fixed wrenches due to its versatility. Its movable jaw allows it to fit different fastener sizes, reducing the need for multiple tools. This adaptability makes it ideal for professionals and DIY enthusiasts alike.

However, it has limitations compared to specialized tools. Fixed wrenches often provide better grip and stability for specific sizes. Torque wrenches are necessary for precision work, such as machinery assembly or automotive repairs. For pipes, a pipe wrench offers superior hold.

In summary, while an adjustable spanner is highly versatile, specialized tools may be better for certain tasks. Evaluate your needs before deciding whether it can fully replace other tools.

How Long Can an Adjustable Spanner Last?

The lifespan of an adjustable spanner depends on its quality and maintenance. High-quality spanners made from durable materials like steel can last decades if cared for properly. Regular cleaning, lubrication, and storage prevent wear and rust.

Frequent use on damaged fasteners or applying excessive force can reduce its longevity. Neglecting maintenance also accelerates tool degradation.

To ensure a long lifespan:

- Clean the tool after every use.

- Lubricate the moving parts regularly.

- Store it in a dry, safe place.

With proper care, an adjustable spanner can serve you efficiently for years.

Tips for Maintaining Your Spanner Wrench

Proper care ensures your adjustable spanner wrench lasts for years. Simple habits can prevent wear and maintain peak performance.

First, clean the tool after each use. Wipe off grease, dirt, and metal shavings. Use a cloth dampened with light oil if necessary. Therefore, grime doesn’t build up in the thread groove.

Second, inspect the jaw edges regularly. Chips or burrs reduce grip. File them smooth if damaged. Sharp, flat surfaces ensure solid contact with fasteners.

Third, lubricate the adjusting screw. Apply a drop of machine oil to the worm gear monthly. Then rotate the dial back and forth to spread it. Hence, movement stays smooth.

Fourth, store it properly. Keep it in a dry toolbox away from moisture. Humidity leads to rust. Also, avoid leaving it in direct sunlight for long periods.

Fifth, avoid over-tightening the jaw. Excessive pressure strains the screw and weakens the mechanism. Adjust until snug, then stop.

Sixth, never use a pipe extension for extra leverage. This can bend the handle or strip internal parts. If more force is needed, switch to a breaker bar or longer wrench.

Seventh, check calibration occasionally. Compare the jaw opening to a ruler or caliper. Misaligned scales lead to incorrect settings. Replace the tool if accuracy drops.

By following these steps, your adjustable spanner wrench will remain reliable and safe.

Final Thoughts: Why the Adjustable Spanner Wrench Belongs in Every Kit

Final Thoughts: Why the Adjustable Spanner Wrench Belongs in Every Kit

The adjustable spanner wrench is more than just a handy tool—it’s a symbol of practical ingenuity. From home repairs to professional workshops, it bridges the gap between simplicity and functionality. Its ability to adapt to countless fastener sizes makes it irreplaceable in dynamic environments.

Indeed, whether you’re changing a tire, repairing a sink, or maintaining farm equipment, the adjustable spanner wrench gets the job done. It empowers users to act confidently without waiting for the perfect tool. Moreover, advancements in design have made modern versions stronger, more precise, and more comfortable than ever.

Therefore, if you don’t already own one, now is the time to add an adjustable spanner wrench to your collection. Choose a quality model, learn its limits, and maintain it well. Because in moments of need, this single tool can make all the difference. And as long as nuts and bolts exist, the adjustable spanner wrench will remain a trusted companion.