Wrench Sizes: Choosing the Right Wrench for Your Needs

When it comes to tackling mechanical projects or performing everyday repairs, understanding wrench sizes is essential. Whether you’re a professional mechanic or a DIY enthusiast, having the right wrench size can make all the difference in ensuring tasks are completed efficiently and safely. This comprehensive guide delves into the various aspects of wrench sizes, helping you make informed decisions about the tools you use. From identifying different sizes to selecting the appropriate wrench for specific applications, you’ll gain valuable insights that enhance your toolkit and improve your workmanship.

Introduction to Wrenches Sizes

Introduction to Wrenches Sizes

Importance of Understanding Wrench Sizes

Understanding wrench sizes is essential for efficient tool use. It ensures proper grip and prevents damage. Using the wrong size can strip bolts or nuts and cause frustration. Knowing the sizes helps you work faster and saves time. It also avoids errors, making tasks safer and more efficient.

Wrench sizes are crucial for DIY enthusiasts and professionals. Whether working on cars, plumbing, or home repairs, the correct size is key. Choosing the right size avoids unnecessary wear on tools. Understanding how wrench sizes work also helps organize tools effectively.

Metric vs. Imperial Systems

Wrenches come in two main systems: metric and imperial. Metric sizes are measured in millimeters. These are common in most countries and modern machinery. Imperial sizes are measured in inches and used in older or U.S.-made equipment.

Metric sizes often range from 6mm to 32mm for common tasks. Imperial sizes might include fractions like 3/8″ or 7/16″. Knowing which system applies to your project prevents confusion. Sometimes, tools are sold as sets combining both systems for versatility.

Metric wrenches offer consistent sizing for global standards. Imperial tools are useful for specific applications, especially in the U.S. Choose the right system based on the equipment you are working on to ensure compatibility.

Standard Wrenches Sizes for Everyday Use

Wrench sizes vary depending on the tools and tasks at hand. For everyday use, knowing the most common sizes is important. These sizes make regular tasks like home repairs or maintenance easier and more efficient.

Commonly Used Metric Wrenches

Metric wrenches are measured in millimeters. They are widely used in modern machines and vehicles. Common metric sizes include 6mm, 8mm, 10mm, 13mm, 15mm, 17mm, and 19mm. These sizes fit most nuts and bolts in global applications.

When working with tools or machinery, metric sets often range from 6mm to 22mm. For larger work, wrenches can go up to 32mm or more. Metric wrenches offer precision and compatibility for international equipment.

Commonly Used Imperial Wrenches

Imperial wrenches are measured in inches or fractions. They are popular in older machinery and U.S.-made tools. Common imperial sizes include 3/8″, 7/16″, 1/2″, 9/16″, 5/8″, and 3/4″. These sizes are standard for varied applications.

Imperial wrench sets often start at 1/4″ and go up to 1″ or larger. They are frequent in plumbing, automotive repairs, and heavy-duty tasks. Imperial wrenches fit specific equipment found mostly in North America.

Understanding both metric and imperial systems ensures you’re ready for diverse projects. Make sure to check your equipment type before starting.

Specialized Wrenches Sizes and Uses

Specialized Wrenches Sizes and Uses

When tackling specific tasks, standard wrench sizes may not always meet your needs. Some jobs require specialized wrenches designed for unique applications. Below, we’ll explore two common scenarios where specialized wrench sizes are essential.

Wrench Sizes for Automotive Repairs

Automotive repairs often rely on both metric and imperial wrench sizes. For modern vehicles, metric wrenches dominate. Common sizes include 10mm, 12mm, 13mm, and 17mm. These are used for bolts in engine bays, brakes, and suspension systems.

For older or U.S.-made vehicles, imperial wrenches are common. Sizes like 3/8″, 7/16″, and 1/2″ are frequently used. Mechanics also use combination wrenches that feature an open-end and a box-end in one tool.

Specialized automotive maintenance, such as spark plug removal, requires socket wrenches in specific sizes. Spark plug sizes typically range from 5/8″ to 13/16″. For tight spaces, swiveling or flexible-head wrenches improve accessibility.

Always check the vehicle’s manual before starting. This ensures you’re using the right wrench size and type for each part.

Plumbing and Pipe Wrench Sizes

Plumbing tasks need sturdy wrenches designed for gripping and turning pipes. Pipe wrenches, adjustable in size, are ideal for this purpose. Common pipe wrench sizes include 10-inch, 14-inch, and 18-inch models. These cover most residential plumbing jobs.

Smaller sizes, like the 6-inch wrench, are perfect for tight spaces. Larger options, like 24-inch or more, are available for industrial work or heavy-duty pipes.

Other plumbing-specific wrenches include basin wrenches for faucet nuts, which reach narrow and recessed spaces. Adjustable crescent wrenches are also indispensable for threaded pipe fittings.

The correct size ensures you avoid damaging delicate surfaces or over-tightening pipes. Using the right wrench enhances the efficiency and safety of plumbing tasks.

How to Measure Wrench Sizes Correctly

Knowing how to measure wrench sizes correctly is essential for selecting the right tool. Accurate measurements prevent mistakes and ensure the wrench fits properly for the job. This section guides you through tools and tips for precise measurements.

Tools for Measuring Wrenches

Several tools are available to measure wrench sizes accurately. Commonly used tools include:

- Calipers: A caliper measures the width of bolt heads or nuts precisely. Digital calipers provide quick readings.

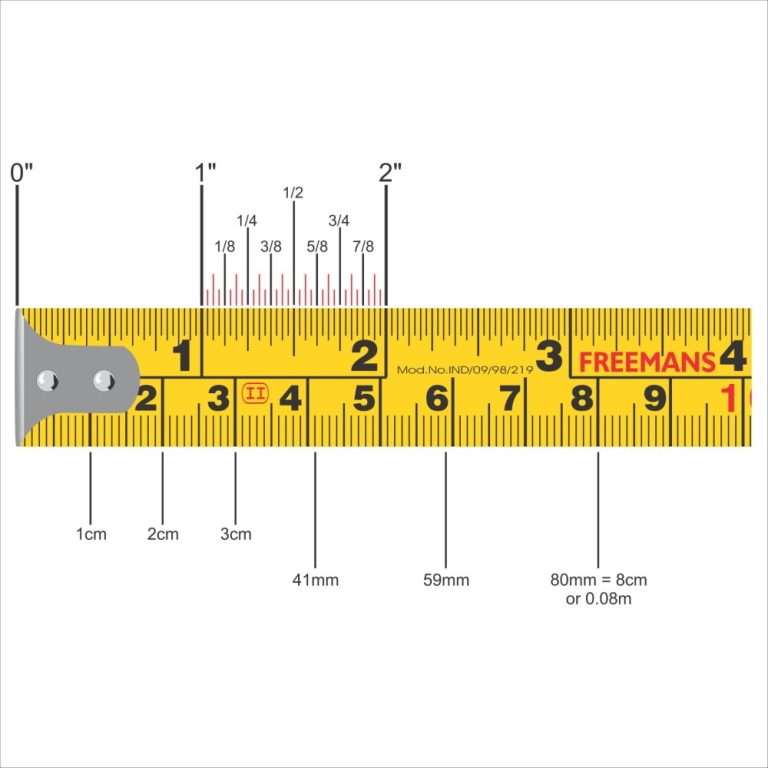

- Rulers or Tape Measures: These simple tools work for larger wrenches or bolts. Ensure accurate readings by aligning the tool properly.

- Gauge Templates: These templates have pre-cut sizes for referencing wrench dimensions. They are easy to use and portable.

- Sizing Charts: Many toolkits include sizing charts for quick identification of wrench measurements.

- Thread Pitch Gauge: This is used to measure the thread size of bolts and nuts. It’s helpful for matching bolts with the right wrench size.

Keep these tools handy to ensure easy and precise wrench measurement while working on projects.

Tips for Accurate Measurements

Follow these tips for accurate wrench size measurements:

- Measure Twice: Double-check measurements for confirmation. This avoids errors and ensures the wrench fits perfectly.

- Align Properly: Align the measuring tool correctly with the bolt or nut. Misalignment can cause inaccurate readings.

- Remove Obstructions: Clean bolts or nuts before measuring to eliminate debris or dirt affecting size estimation.

- Know the System: Identify whether the measurement is in metric or imperial. Mistaking the system can lead to incompatible tools.

- Check Manufacturer Guidelines: Many manuals list bolt sizes, saving time on measurement.

- Use a Consistent Method: Always use the same tool and approach for measuring, ensuring uniform results.

Proper tools and techniques simplify measuring wrench sizes and guarantee the correct fit for any task.

Choosing the Right Wrenches Sizes for the Job

Choosing the Right Wrenches Sizes for the Job

Selecting the correct wrench size is crucial for successful and efficient work. It ensures tools grip securely and prevents damage. To choose properly, consider several key aspects relevant to your specific task.

Factors to Consider

- Type of Bolt or Nut: Identify whether bolts or nuts are metric or imperial. This determines the wrench system.

- Material of the Surface: Softer materials may need adjustable wrenches to avoid stripping or damaging surfaces.

- Equipment or Machinery Used: Match wrench size to the project, such as cars, plumbing, or household repairs.

- Accessibility: Some areas require wrenches with swiveling heads or shorter handles for tight spaces.

- Torque Requirement: Use proper wrench sizes to apply the needed force without overtightening.

- Reference Manuals: Check guidelines provided by equipment manufacturers. These often list compatible wrench sizes.

Carefully weighing these factors increases precision and reduces errors during your project.

Avoiding Common Mistakes

- Using Incorrect Systems: Don’t mix metric and imperial sizes. This causes slippage and damages tools.

- Forcing a Fit: Avoid using wrenches that don’t fit properly. This can strip nuts or bolts.

- Neglecting Measurements: Always measure carefully to ensure a proper match between wrench and bolt.

- Ignoring Wear and Tear: Replace worn-out or damaged wrenches. These can fail under stress.

- Overlooking Task Needs: Use specialized wrenches for specific tasks, like automotive or plumbing jobs.

- Improper Tool Handling: Handle wrenches correctly. Misuse leads to inefficient work or physical injury.

Following these tips will enhance your efficiency and ensure the longevity of your tools.

Maintaining and Organizing Wrenches

Maintaining and Organizing Wrenches

Keeping wrenches properly maintained and organized improves efficiency and extends their lifespan. This section outlines effective methods for storage and care.

Proper Storage Techniques

Organizing wrenches is key to avoiding loss and improving workflow. Use these storage techniques:

- Toolboxes with Compartments: Store wrenches in labeled compartments for easy identification.

- Wall Pegboards: Hang wrenches on wall-mounted pegboards for quick access and visibility.

- Roll-Up Pouches: Use roll-up pouches for portable storage, especially for wrench sets.

- Magnetic Trays: Keep wrenches in magnetic trays to prevent movement or scattering.

- Drawer Liners: Use foam or rubber liners in drawers to keep wrenches from sliding.

- Sort by Usage: Group wrenches by size or frequency of use for convenience.

Proper storage saves time and protects tools from unnecessary damage.

Cleaning and Care

Cleaning wrenches regularly ensures optimal performance and prevents rust or wear. Follow these care tips:

- Use a Soft Cloth: Wipe wrenches after each use to remove dirt and grease.

- Apply Oil: Coat wrenches with machine oil to prevent corrosion.

- Inspect for Damage: Check for cracks or wear and replace damaged wrenches promptly.

- Store in Dry Areas: Avoid moisture-rich spaces to minimize rust risks.

- Periodic Deep Cleaning: Soak wrenches in warm, soapy water for thorough cleaning. Dry them immediately.

- Avoid Harsh Chemicals: Use mild cleaning agents to protect wrench materials from degradation.

Regular care ensures your wrenches remain in good condition and ready for use.

Frequently Asked Questions About Wrench Size

When it comes to tools, having quick answers is vital. These FAQs on wrench sizes provide simple solutions for common problems. If you’re unsure about wrench sizing or face unexpected issues during a project, these tips can save time and prevent mistakes.

How to Identify the Correct Wrench Size Quickly

Choosing the right wrench size quickly can make any job smoother. Here are some tips:

- Check the Bolt or Nut Markings: Many bolts and nuts have size markings on them. Use these as a guide.

- Use a Sizing Chart: Keep a wrench sizing chart in your toolkit for instant reference.

- Match with a Caliper: A caliper gives precise measurements of bolt head widths or nut diameters.

- Test Multiple Wrenches: Start with a smaller wrench and adjust until you find the correct fit.

- Organized Wrench Sets: Keep your wrenches sorted by size for quick access and minimal confusion.

- Understand the System (Metric or Imperial): Make sure you’re using wrenches compatible with your bolts or nuts.

What to Do When a Wrench Doesn’t Fit

Sometimes, the chosen wrench may not fit the bolt or nut properly. Here’s what you can do:

- Double-Check the Measurement: Re-measure the bolt or nut to verify the size.

- Clean the Surface: Dirt or rust on bolts may prevent a proper fit. Clean them thoroughly.

- Switch to Another System: Try a metric wrench if imperial fails, or vice versa.

- Use an Adjustable Wrench: These allow you to customize the size for a perfect match.

- Try a Socket Wrench: These are more effective for rounded or hard-to-reach bolts.

- Check Bolt Conditions: Damaged bolts might need replacing or resizing before continuing.

These steps ensure efficiency and reduce any risks of tool or part damage.

Conclusion: Mastering Wrench Size for Better Tool Efficiency

Conclusion: Mastering Wrench Size for Better Tool Efficiency

Understanding and mastering wrench sizes is fundamental for anyone involved in mechanical work, DIY projects, or routine maintenance tasks. By familiarizing yourself with the various types of wrenches, their sizes, and proper usage techniques, you enhance your ability to perform tasks efficiently and safely. Moreover, selecting the right wrench size prevents damage to fasteners and tools, ensuring long-term reliability and durability in your toolkit.

Investing in a comprehensive wrench set, maintaining your tools properly, and following best practices for wrench usage all contribute to a more effective and enjoyable working experience. Whether you’re assembling furniture, repairing vehicles, or working on industrial machinery, the right wrench size is key to achieving professional results. Embrace the knowledge of wrench sizes, and watch as your projects become smoother, more efficient, and ultimately more successful.

By prioritizing the correct selection and maintenance of wrench sizes, you not only improve your tool efficiency but also extend the lifespan of your wrenches. This proactive approach ensures that you are always prepared to handle any mechanical challenge that comes your way. Embrace the importance of wrench sizes and equip yourself with the right tools to achieve excellence in every task.