5/16 on Tape Measure: Guide for Accurate Measuring Techniques

When embarking on any DIY project, precision is paramount. One often overlooked but crucial aspect of accurate measurements is understanding the 5/16 on tape measure. Whether you’re a seasoned craftsman or a beginner enthusiast, mastering this specific fractional measurement can significantly enhance the quality of your work. In this comprehensive guide, we will delve into the intricacies of utilizing the 5/16-inch mark on a tape measure, exploring its applications, common pitfalls, and advanced techniques to ensure your projects are executed with the utmost accuracy.

Understanding the 5/16 Inch Mark on Your Tape Measure

Understanding the 5/16 Inch Mark on Your Tape Measure

The Basics of Tape Measure Fractional Marks

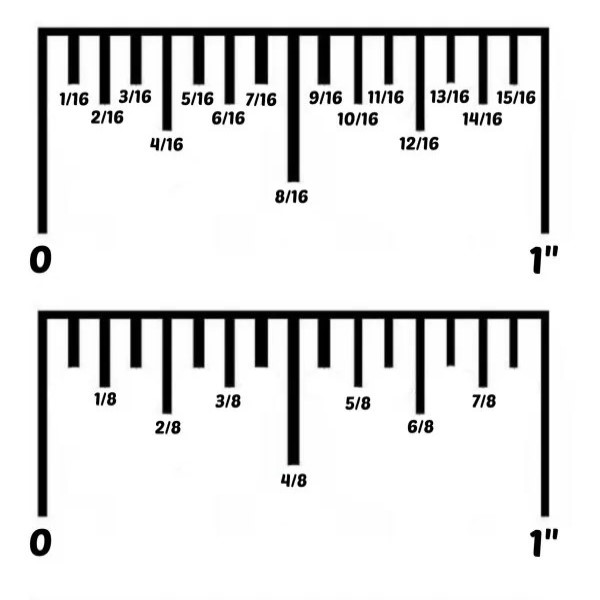

Tape measures are fundamental tools in any DIY toolkit, featuring a series of incremental markings that denote various measurements. Among these, the 5/16 on tape measure stands out as a critical fractional unit, especially in tasks requiring precision. Typically, tape measures are marked in fractions of an inch, and knowing how to interpret these marks is essential for accurate measurements.

Locating the 5/16 Inch Mark

To locate the 5/16-inch mark on your tape measure, start by identifying the smallest incremental unit, often 1/16 of an inch. Counting five of these increments will bring you to the 5/16-inch mark. It’s important to familiarize yourself with the spacing and visibility of these marks to ensure swift and accurate reading during your projects.

Importance of the 5/16 Inch Measurement

The 5/16-inch measurement is particularly significant in various DIY applications, such as woodworking, metalworking, and construction. Its precision allows for meticulous cuts, accurate fits, and seamless assemblies, contributing to the overall quality and durability of your projects. Understanding and accurately applying the 5/16 on tape measure can make the difference between a successful build and a flawed one.

Practical Applications of the 5/16 Inch Mark

Utilizing 5/16 Inch in Woodworking

In woodworking, the 5/16 on tape measure is frequently used for measuring wood dimensions, ensuring that joints fit perfectly, and that cuts are precise. For instance, when creating a dovetail joint, the 5/16-inch mark can help in aligning the tails and pins accurately, resulting in a strong and aesthetically pleasing connection.

Measuring and Marking Wood

When measuring and marking wood, start by aligning the tape measure with the edge of the wood piece. Carefully note the 5/16-inch mark and use a pencil or marking tool to indicate the measurement. This practice ensures that your cuts are accurate and that pieces fit together seamlessly.

Cutting Wood at 5/16 Inches

For cuts requiring a 5/16-inch measurement, such as notches or slots, utilizing the 5/16 mark ensures precision. Aligning the saw or cutting tool with this mark helps maintain consistency across multiple cuts, essential for projects like shelving or cabinetry where uniformity is key.

Applying 5/16 Inch in Metalworking

Metalworking projects also benefit from the precision of the 5/16 on tape measure. Whether you’re cutting metal rods, aligning components, or creating detailed designs, the 5/16-inch measurement plays a pivotal role.

Aligning Metal Pieces

When aligning metal pieces for welding or bolting, the 5/16-inch mark ensures that components are spaced correctly. This precision is vital for structural integrity and the overall functionality of the finished product.

Creating Detailed Designs

For intricate metal designs, such as decorative elements or machinery parts, the 5/16-inch mark assists in maintaining accurate dimensions. This accuracy is crucial for parts that need to fit together perfectly or function as intended within a larger assembly.

The Role of 5/16 Inch in Construction

In construction, the 5/16 on tape measure is indispensable for various measurements, from framing to installing fixtures. Its accuracy ensures that buildings are structurally sound and that installations, such as windows and doors, fit properly.

Framing and Structural Measurements

During framing, precise measurements are essential to ensure that walls are straight and plumb. Using the 5/16-inch mark helps in laying out studs and other structural elements accurately, contributing to the overall stability of the construction.

Installing Fixtures and Fittings

Whether installing cabinets, countertops, or other fixtures, the 5/16-inch measurement ensures that everything fits snugly and functions correctly. This precision minimizes gaps and misalignments, leading to a professional and polished finish.

Converting 5/16 Inch to Other Units

Converting 5/16 Inch to Other Units

Fractional to Decimal Conversion

Understanding how to convert the 5/16 on tape measure to decimal units is beneficial, especially when working with tools or materials that require decimal measurements. The 5/16-inch mark converts to 0.3125 inches in decimal form, providing a precise equivalent that can be easily used in calculations and measurements.

Fractional to Millimeter Conversion

For projects that require metric measurements, converting 5/16 inches to millimeters is essential. The 5/16-inch mark is approximately 7.9375 millimeters. Knowing this conversion allows for seamless integration of metric measurements into your projects, particularly useful in international or specialized applications.

Practical Conversion Tips

To simplify these conversions, consider using a calculator or a conversion chart. Additionally, memorizing common fractional to decimal and millimeter equivalents can speed up your measuring process, making your workflow more efficient and reducing the likelihood of errors.

Avoiding Common Measurement Mistakes with 5/16 Inch

Misreading the Tape Measure

One common mistake when using the 5/16 on tape measure is misreading the fractional marks. Ensuring that you correctly identify the 5/16-inch mark and distinguish it from adjacent marks is crucial for maintaining measurement accuracy.

Incorrect Alignment

Another frequent error is incorrect alignment of the tape measure with the material being measured. Always ensure that the tape measure is flat against the material and that the starting point is exact to prevent skewed measurements.

Not Accounting for Tape Flexibility

Tape measures can sometimes flex, leading to inaccurate readings if not handled properly. To avoid this, hold the tape firmly and ensure it remains straight and taut during measurement. This practice helps maintain the integrity of the 5/16-inch measurement.

Practical Examples of Mistakes and Solutions

For instance, in woodworking, misreading the 5/16-inch mark can result in uneven joints, compromising the structure’s stability. To prevent this, double-check your measurements and consider using additional markers or guides to ensure accuracy. Similarly, in metalworking, incorrect alignment can lead to misaligned components, so taking the time to verify measurements before cutting or assembling is essential.

Advanced Techniques for Utilizing 5/16 Inch Measurements

Using Templates and Guides

For projects that require repetitive use of the 5/16-inch measurement, creating templates or guides can enhance precision and efficiency. These tools help maintain consistent measurements across multiple instances, reducing the likelihood of errors and speeding up the workflow.

Double-Checking Measurements

Implementing a habit of double-checking the 5/16 on tape measure before making cuts or adjustments ensures that any measurement errors are caught early. This practice is especially important in complex projects where precision is critical to the overall success.

Incorporating Technology

Leveraging technology, such as digital tape measures or measurement apps, can complement traditional tape measures. These tools often provide additional features, such as automatic unit conversion and digital readouts, which can enhance the accuracy and ease of using the 5/16-inch mark.

Practical Applications in Various DIY Projects

Practical Applications in Various DIY Projects

Woodworking and Carpentry

In woodworking and carpentry, the 5/16-inch mark is frequently used for tasks such as cutting dowels, creating precise joints, and aligning pieces accurately. For example, when building a bookshelf, using the 5/16-inch measurement ensures that each shelf is evenly spaced and securely attached to the frame.

Sewing and Upholstery

In sewing and upholstery, precise measurements are crucial for achieving professional results. The 5/16 on tape measure is used for tasks like spacing buttons, measuring fabric for seams, and ensuring uniform padding thickness. Accurate measurements lead to well-fitted garments and durable upholstery.

Metalworking and Fabrication

Metalworking projects, such as fabricating frames or creating custom hardware, rely on the 5/16-inch mark for precise cuts and alignments. This measurement ensures that metal pieces fit together correctly, maintaining the integrity and functionality of the final product.

Home Improvement and Renovation

During home improvement projects, such as installing cabinets, fitting tiles, or mounting fixtures, the 5/16-inch measurement provides the necessary precision. Accurate measurements ensure that installations are level, secure, and aesthetically pleasing, contributing to the overall quality of the renovation.

Enhancing Your Measuring Skills with 5/16 Inch Accuracy

Practice Makes Perfect

Improving your ability to accurately use the 5/16 on tape measure comes with practice. Regularly measuring and marking materials using this fraction helps build muscle memory, making it easier to quickly and accurately identify the 5/16-inch mark during projects.

Learning from Professionals

Seeking advice and tips from experienced professionals can enhance your measuring skills. Professionals often have techniques and shortcuts that streamline the measurement process, increasing both speed and accuracy when using the 5/16-inch mark.

Utilizing Quality Tools

Investing in a high-quality tape measure ensures that the fractional marks, including the 5/16-inch mark, are clear and easy to read. A durable tape measure that maintains its accuracy over time is essential for consistently precise measurements in all your projects.

5/16 on Tape Measure: Conversion Guide to Decimals and Millimeters

5/16 on Tape Measure: Conversion Guide to Decimals and Millimeters

Understanding how to convert the 5/16 on tape measure to other units is essential, especially when working on projects that require both imperial and metric measurements. Let’s explore the conversion process in detail.

Fraction to Decimal Conversion

The first step in converting 5/16 inches to decimal is to divide the numerator (5) by the denominator (16):

5÷16=0.3125

Therefore, 5/16 inches is equal to 0.3125 inches in decimal form. This conversion is particularly useful when working with digital tools or software that require decimal inputs.

Fraction to Millimeters Conversion

To convert 5/16 inches to millimeters, you multiply the decimal value by 25.4 (since one inch equals 25.4 millimeters):

0.3125×25.4=7.9375 mm

Thus, 5/16 inches is approximately 7.94 millimeters. This precise conversion is beneficial when working with metric measurements, ensuring compatibility and accuracy across different measurement systems.

Practical Conversion Tips

To simplify these conversions, consider using the following tips:

- Use a Calculator: A basic calculator can quickly perform these conversions, ensuring accuracy without manual calculations.

- Conversion Charts: Keep a conversion chart handy for frequent reference, making it easier to switch between units without interrupting your workflow.

- Memorize Common Equivalents: Familiarize yourself with common fractional to decimal and metric conversions to enhance efficiency during measurements.

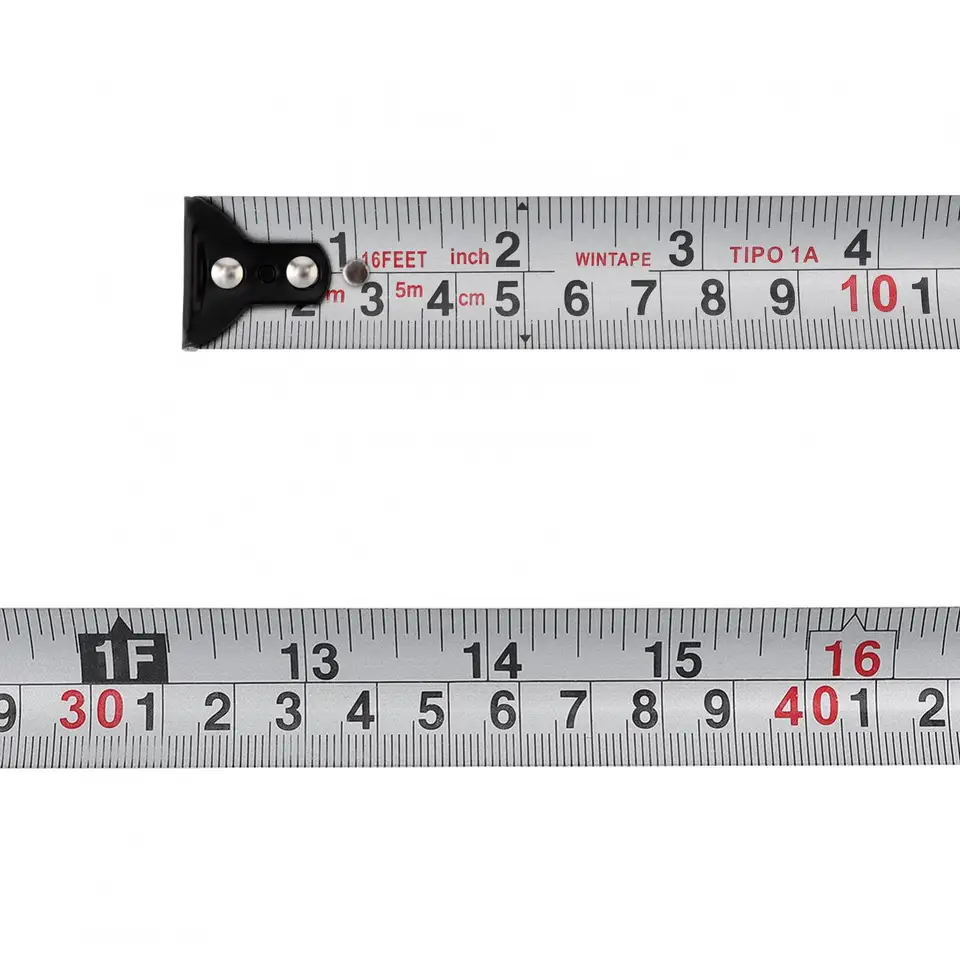

Utilizing Digital Tools for Conversion

In today’s digital age, numerous tools can assist with these conversions. Digital tape measures often come with built-in conversion features, automatically translating 5/16 inches to decimal or millimeter equivalents. Additionally, smartphone apps designed for measurement can provide instant conversions, streamlining the measurement process and reducing the potential for errors.

Common Mistakes and How to Avoid Them in Construction

Accurate measurements are critical in construction to ensure safety and structural integrity. However, even minor mistakes can lead to significant issues. Here, we explore common errors related to the 5/16 on tape measure and provide strategies to avoid them.

Common Measurement Errors

Misreading the 5/16 Inch Mark

One of the most frequent mistakes is misreading the 5/16-inch mark, especially under poor lighting or with a worn-out tape measure. This can lead to incorrect cuts or misaligned components.

Improper Tape Measure Alignment

Incorrect alignment of the tape measure relative to the material can result in skewed measurements. Ensuring the tape is straight and firmly pressed against the material is essential for accuracy.

Neglecting Tape Flexibility

Allowing the tape to flex or bow can distort measurements. Keeping the tape measure taut and straight during measurement prevents such errors.

Strategies to Avoid Measurement Mistakes

Double-Check Measurements

Always double-check your measurements before making cuts or placements. This simple practice can catch errors before they become costly mistakes.

Use Measuring Aids

Employ tools such as squares, levels, and marking gauges to ensure the tape measure is aligned correctly. These aids provide additional reference points, enhancing measurement accuracy.

Maintain Your Tape Measure

Regularly inspect your tape measure for wear and tear. Replace it if the markings are faded or if the tape itself is damaged, ensuring that the 5/16-inch mark remains clear and accurate.

Real-World Examples and Solutions

Consider a scenario where a carpenter misreads the 5/16-inch mark, leading to misaligned shelves. By implementing a double-checking system and using a level to verify measurements, the carpenter can prevent such errors, ensuring that each shelf is correctly positioned and securely installed.

Another example involves incorrect tape alignment during framing. Using a square to align the tape measure ensures that each stud is placed accurately, maintaining the structural integrity of the building and preventing costly adjustments later in the construction process.

Advanced Techniques for Precision Cutting

For those seeking to elevate their craftsmanship, mastering advanced techniques using the 5/16 on tape measure is essential. These methods enhance precision and efficiency, leading to superior results in your projects.

Utilizing Auxiliary Tools for Enhanced Accuracy

Incorporate auxiliary tools such as clamps, marking tools, and cutting guides to maintain the accuracy of the 5/16-inch measurement during cutting processes. These tools provide stability and reference points, ensuring that each cut maintains the desired measurement consistently.

Multi-Stage Measurement and Verification

Implement a multi-stage measurement system where you measure, mark, and verify the 5/16-inch measurement at each step. This process ensures that any discrepancies are identified and corrected early, maintaining the integrity of the measurement throughout the project.

Template Creation for Repetitive Cuts

Creating templates for repetitive cuts involving the 5/16-inch measurement can significantly enhance precision. Templates act as guides, ensuring that each cut is identical and meets the necessary specifications. This is particularly useful in projects requiring multiple identical components, such as cabinetry or furniture making.

Leveraging Professional Insights

Learn from the techniques and insights of professional craftsmen who utilize the 5/16-inch measurement in their work. Professionals often develop unique methods for maintaining accuracy, such as specific marking techniques or specialized cutting tools, which can be adapted to your projects for improved results.

Using 5/16-Inch Measurements in Sewing and Upholstery

Beyond construction and woodworking, the 5/16 on tape measure plays a vital role in sewing and upholstery. Precision in these fields ensures high-quality finishes and durable results. Here, we explore how to effectively use the 5/16-inch mark in these creative endeavors.

Accurate Fabric Cutting and Marking

In sewing, precise measurements are crucial for cutting fabric to the correct size. The 5/16-inch mark is often used for intricate cuts and ensuring uniform seam allowances. Accurate marking with the 5/16-inch measurement prevents fabric wastage and ensures that pieces fit together seamlessly.

Marking Techniques

Use tailor’s chalk or fabric markers to clearly indicate the 5/16-inch mark on your fabric. Double-check the placement to ensure consistency across all pieces, which is especially important in garment construction where precise seams are necessary for a professional finish.

Spacing Buttons and Fasteners

When spacing buttons or other fasteners, the 5/16-inch measurement ensures uniformity and aesthetic appeal. Even spacing contributes to the garment’s overall look and functionality, preventing buttons from being too close or too far apart.

Upholstery Padding and Fabric Placement

In upholstery, the 5/16-inch mark can guide the placement of padding and fabric. Accurate measurements ensure that cushions are evenly filled and that fabric is stretched correctly over frames, resulting in a polished and comfortable final product.

Managing Fabric Stretch and Shrinkage

Account for fabric stretch and shrinkage by incorporating the 5/16-inch measurement into your cutting and sewing plans. This consideration prevents distortions and ensures that the final piece maintains its intended shape and size after washing or use.

Enhancing Accuracy with the 5/16 Inch Mark

Enhancing Accuracy with the 5/16 Inch Mark

Developing a Consistent Measurement Routine

Consistency is key to achieving precision with the 5/16 on tape measure. Develop a regular measurement routine that includes standardized steps for measuring, marking, and verifying the 5/16-inch measurement. This routine helps minimize errors and ensures that each project maintains a high level of accuracy.

Incorporating Precision Tools

Use precision tools such as fine-point pencils, measuring gauges, and laser guides to enhance the accuracy of the 5/16-inch measurement. These tools provide clear and precise marks, making it easier to follow through with exact measurements during cutting and assembly.

Training and Skill Development

Invest time in training and skill development to improve your ability to use the 5/16-inch mark effectively. Practice measuring and marking with various materials and tools to build confidence and proficiency, ensuring that you can rely on the 5/16-inch measurement for consistent results across different projects.

Quality Assurance Measures

Implement quality assurance measures, such as regular inspections and measurements by multiple individuals, to ensure that the 5/16-inch measurement is applied accurately. These measures help catch any discrepancies early, maintaining the overall quality and integrity of your work.

Conclusion

Mastering the 5/16 on tape measure is a fundamental skill that enhances precision and quality across a wide range of DIY projects. From woodworking and metalworking to sewing and upholstery, understanding and accurately applying this fractional measurement ensures that your work meets professional standards. By avoiding common mistakes, utilizing advanced techniques, and incorporating practical applications, you can elevate your craftsmanship and achieve flawless results in every project. Embrace the precision of the 5/16-inch mark on your tape measure, and watch as your DIY endeavors transform into expertly crafted masterpieces.