Marks on a Tape Measure: A Guide for Accurate Measurements

Accurate measurements are fundamental to the success of any project, whether you’re a professional tradesperson, a DIY enthusiast, or simply tackling home improvement tasks. Central to achieving precision is understanding the marks on a tape measure. These markings not only facilitate precise measurements but also enhance the usability and functionality of the tape measure itself. In this comprehensive guide, we will delve into the various marks on a tape measure, their significance, and how to effectively utilize them to ensure your measurements are always spot-on.

The Anatomy of a Tape Measure

The Anatomy of a Tape Measure

Basic Structure and Components

A tape measure is a versatile tool composed of several key components that work together to provide accurate measurements. Typically, it consists of a flexible tape made from materials such as steel, fiberglass, or cloth, housed within a durable case. At one end of the tape, you’ll find the hook, which anchors the tape to the starting point of your measurement.

Understanding the Marks on a Tape Measure

The marks on a tape measure are more than just lines; they represent a standardized system of measurement that ensures consistency and accuracy.

Major Units and Subdivisions

The most prominent marks on a tape measure denote the primary units of measurement, typically inches or centimeters, depending on the region. For example, in the United States, tape measures usually display inches with smaller subdivisions representing fractions of an inch. Conversely, metric tape measures, commonly used worldwide, display centimeters and millimeters.

Inches and Their Divisions

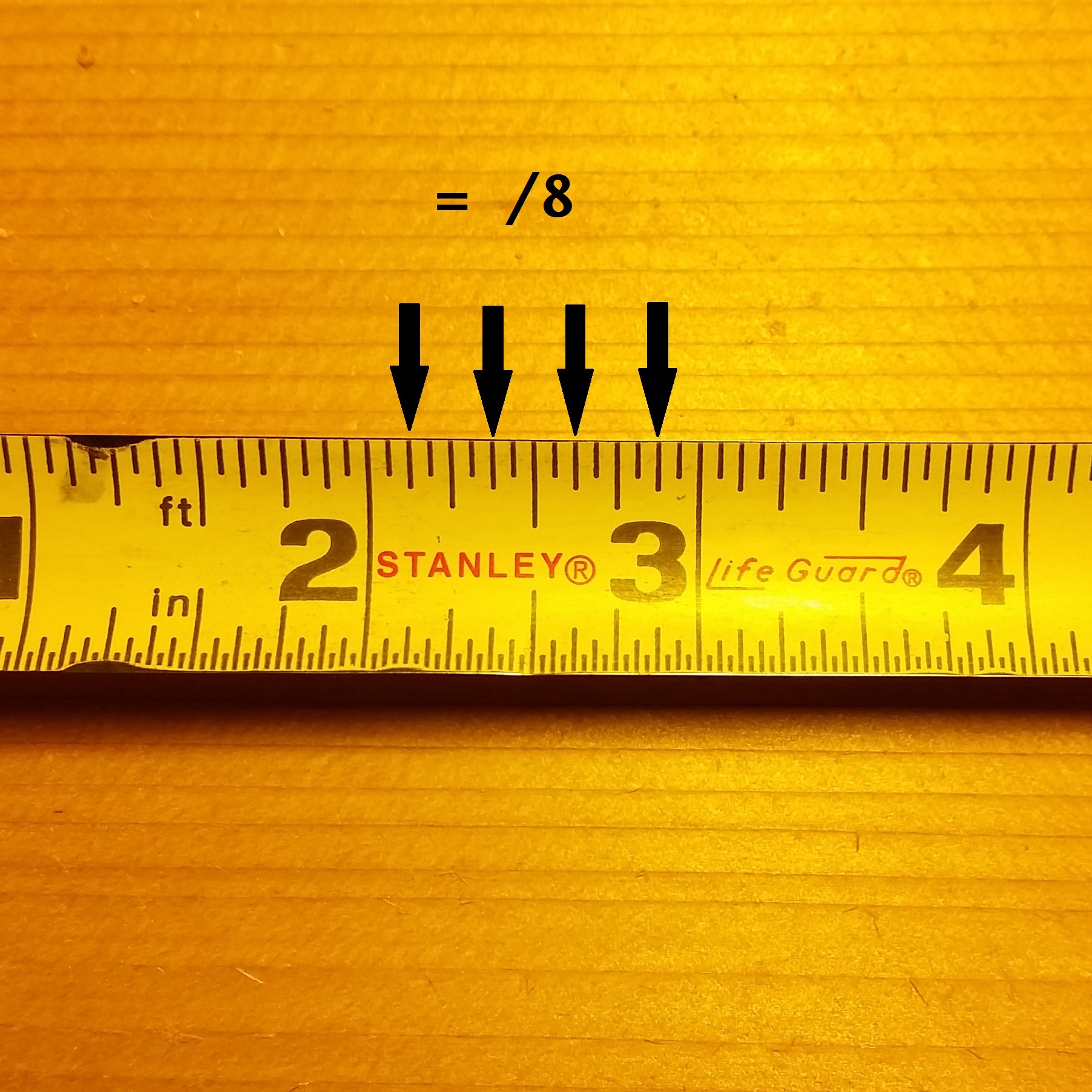

On an imperial tape measure, each inch is divided into smaller increments:

- Whole Inches: The largest numbered marks indicate whole inches.

- Half Inches: The intermediate marks between whole inches indicate half-inch increments.

- Quarter Inches: Further subdivisions represent quarter-inch increments.

- Eighth and Sixteenth Inches: The smallest lines denote even finer divisions, such as eighths and sixteenths of an inch.

These subdivisions allow for precise measurements, accommodating a wide range of applications from carpentry to tailoring.

Centimeters and Millimeters

Metric tape measures feature a straightforward system:

- Centimeters (cm): The main numbered marks correspond to whole centimeters.

- Millimeters (mm): Each centimeter is divided into ten millimeter increments, providing detailed measurement precision.

- Sub-Millimeter Marks: Some high-precision tape measures include additional markings for sub-millimeter accuracy, beneficial in fields requiring extreme precision.

Importance of Accurate Marks on a Tape Measure

Ensuring Precision in Measurements

Accurate marks on a tape measure are crucial for obtaining precise measurements. Whether you’re cutting materials, aligning components, or estimating dimensions for a project, the reliability of your tape measure’s markings directly impacts the quality of your work. Inaccurate marks can lead to errors, resulting in wasted materials, increased costs, and compromised structural integrity.

Enhancing Efficiency and Productivity

Clear and well-marked tape measures streamline the measurement process, allowing you to work more efficiently. When the marks are easy to read and accurately placed, you spend less time double-checking measurements and more time executing your tasks. This efficiency is particularly beneficial in professional settings where time is of the essence and productivity is key.

Facilitating Communication and Standardization

Standardized markings on tape measures ensure that measurements are universally understood, fostering clear communication among professionals. This standardization is essential in collaborative environments, where precision and consistency are non-negotiable. Additionally, it facilitates the seamless exchange of plans, blueprints, and specifications across different teams and disciplines.

Common Marks Found on a Tape Measure

Common Marks Found on a Tape Measure

Numbered Inch and Centimeter Marks

At the forefront of your tape measure, the numbered inch or centimeter marks serve as the primary reference points. These marks indicate the whole units of measurement, providing a clear and immediate understanding of the distance being measured.

Half, Quarter, and Smaller Increments

Between the primary unit marks, you’ll find smaller lines representing fractions of an inch or millimeters. These increments allow for more precise measurements, enabling you to capture finer details essential for intricate tasks.

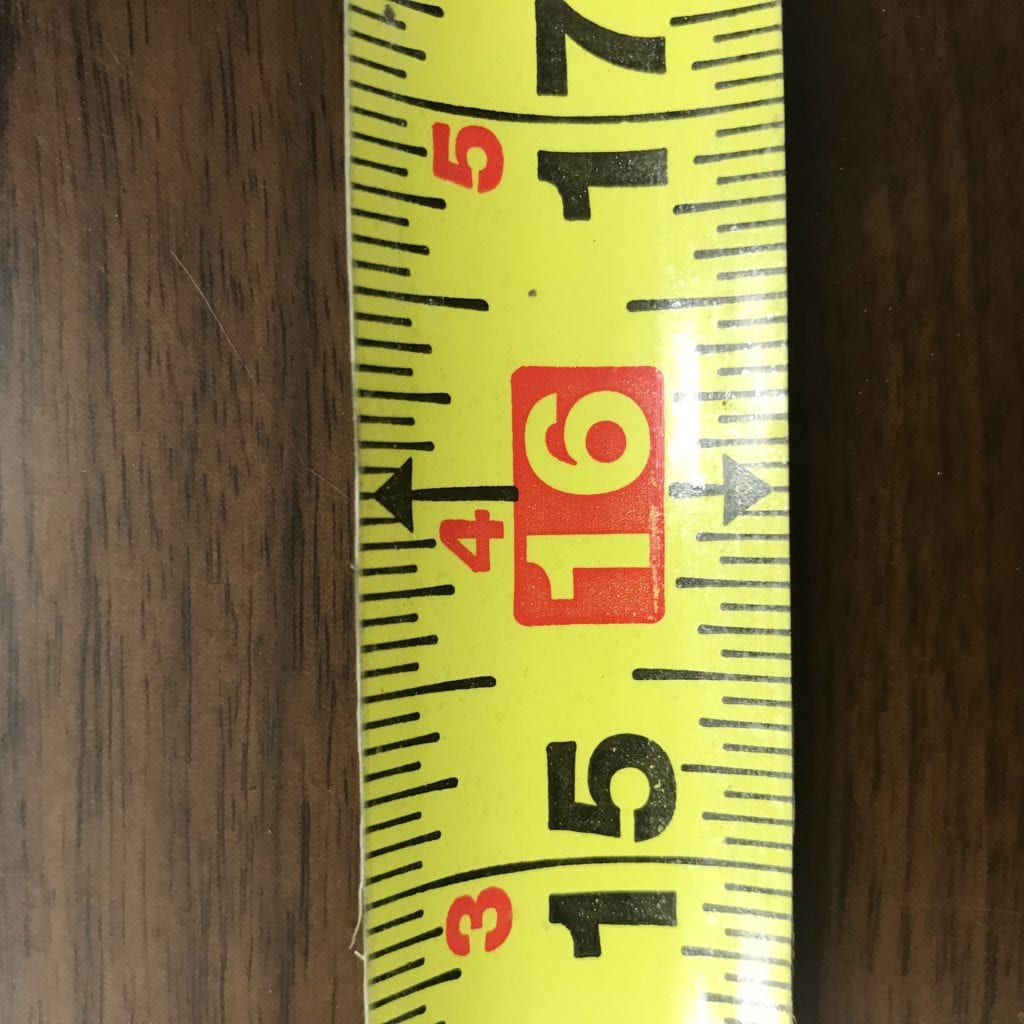

Stud Marks and Click Points

Some tape measures include stud marks or click points, which are indicators that assist in locating studs in walls or other fixed points. These marks are particularly useful in construction and home improvement projects, providing quick reference points that save time and effort.

Tongue Marks and Locking Points

The tongue mark refers to the edge of the tape measure where the hook is attached. This mark helps in aligning the tape measure correctly with the starting point of your measurement. Locking points, often located near significant increments, allow you to secure the tape in place, ensuring stability and preventing accidental retraction during measurement.

Special Feature Marks

Advanced tape measures may incorporate additional marks for specific purposes, such as angle measurements, pitch graphs, or hexagon scales. These specialized marks cater to particular industries and applications, enhancing the tape measure’s versatility and functionality.

Interpreting the Marks on a Tape Measure

Reading Imperial Tape Measures

When using an imperial tape measure, understanding the hierarchy of marks is essential for accurate measurement:

- Start at Zero: Ensure the hook is securely placed at the starting point.

- Whole Inches: Identify the largest numbered marks representing whole inches.

- Half and Quarter Inches: Locate the intermediate marks between whole inches for half and quarter-inch measurements.

- Smaller Fractions: For even more precise measurements, use the smallest lines indicating eighths and sixteenths of an inch.

By systematically interpreting these marks, you can achieve highly accurate measurements suitable for a wide range of tasks.

Reading Metric Tape Measures

Metric tape measures simplify the measurement process with their straightforward system:

- Start at Zero: Place the hook firmly at the starting point.

- Centimeter Marks: Identify the primary numbered marks representing whole centimeters.

- Millimeter Increments: Each centimeter is divided into ten millimeter marks, allowing for detailed measurement.

- Sub-Millimeter Marks: High-precision tapes may include additional marks for finer accuracy.

Metric tape measures are particularly user-friendly, making them ideal for applications that require quick and precise measurements.

Enhancing Measurement Skills with Tape Measure Marks

Proper Alignment Techniques

To maximize the accuracy of your measurements, proper alignment of the tape measure marks is crucial. Begin by ensuring that the hook is securely anchored at the starting point. Align the tape measure parallel to the object being measured, keeping the marks straight and level. This practice minimizes errors caused by misalignment or slanting, ensuring that your measurements reflect the true dimensions of the object.

Utilizing Intermediate Marks for Precision

Intermediate marks, such as half or quarter-inch lines, play a significant role in enhancing measurement precision. By paying close attention to these smaller increments, you can capture more detailed measurements, which is particularly important in tasks that require exactness, such as cabinetry, upholstery, or metalworking.

Leveraging Locking Mechanisms

Many tape measures feature locking mechanisms that allow you to secure the tape in place once the desired measurement is reached. By engaging the lock, you prevent the tape from retracting unexpectedly, ensuring that your measurement remains stable and accurate. This feature is especially useful when working alone or when holding the tape in place is challenging.

Reading Marks from Different Angles

Sometimes, the angle from which you view the tape measure can affect the readability of the marks. To ensure accurate measurements, read the marks from a perpendicular angle whenever possible. This practice reduces parallax errors, where the measurement appears distorted due to the viewing angle, thereby increasing overall accuracy.

Advanced Features and Their Marks

Advanced Features and Their Marks

Magnetic Hooks and Specialized Marks

Some tape measures come equipped with magnetic hooks, which aid in securing the tape to metal surfaces. These hooks simplify measurements in environments where fastening the tape with your hands would be inconvenient. The presence of magnetic hooks is typically indicated by specific marks or symbols on the tape measure, guiding users on how to utilize this feature effectively.

Glow-in-the-Dark Marks for Low-Light Conditions

For tasks performed in low-light environments, glow-in-the-dark marks are invaluable. These special markings fluoresce in the dark, making them easily visible without additional lighting. This feature enhances safety and accuracy, allowing measurements to be taken accurately even in challenging lighting conditions.

Kilogram and Gram Marks for Specialized Industries

In industries where weight measurements are crucial, some tape measures include kilogram and gram marks alongside traditional length measurements. These additional marks cater to specific applications, providing a more comprehensive tool for professionals who require both length and weight measurements.

Maintaining the Accuracy of Tape Measure Marks

Regular Calibration and Inspection

To ensure the ongoing accuracy of the marks on a tape measure, regular calibration and inspection are essential. Periodically check the tape measure against a known standard to verify its precision. Inspect the marks for any signs of wear, fading, or damage, and address any discrepancies promptly to maintain the tool’s reliability.

Proper Storage Practices

Storing your tape measure correctly helps preserve the integrity of its marks. Keep the tape measure in a dry, temperature-controlled environment to prevent moisture damage and prevent the tape from stretching or warping. Use a protective case or sheath to shield the tape from physical damage that could distort the marks.

Cleaning and Care

Regular cleaning of the tape measure ensures that dirt and debris do not obscure the marks. Wipe the tape with a soft, dry cloth to remove any surface contaminants. Avoid using harsh chemicals or abrasive materials that could damage the tape’s surface or erode the marks, thereby compromising measurement accuracy.

Handling with Care

Proper handling of the tape measure extends its lifespan and maintains the clarity of its marks. Avoid dropping the tape measure or subjecting it to excessive force, as impacts can bend or break the tape, distorting the markings. Additionally, refrain from using the tape measure for unintended purposes, such as prying or as a lever, to prevent accidental damage.

Comparing Marks on Different Types of Tape Measures

Comparing Marks on Different Types of Tape Measures

Standard vs. Self-Locking Tape Measures

Standard tape measures rely solely on manual locking mechanisms, which can sometimes be less reliable in maintaining the tape in place. In contrast, self-locking tape measures automatically engage the lock when extended, ensuring that the marks on a tape measure remain stable during measurement. This feature enhances ease of use and accuracy, particularly in dynamic measurement scenarios.

Fiberglass vs. Steel Tape Measures

Fiberglass tape measures are lightweight and flexible, making them ideal for applications that require bending or wrapping the tape around objects. The marks on a tape measure made from fiberglass remain clear and easy to read even when the tape is flexed. On the other hand, steel tape measures are more durable and resistant to wear, suitable for heavy-duty tasks. The choice between fiberglass and steel tapes depends on the specific requirements of your projects and the environments in which you work.

Practical Applications of Tape Measure Marks

Construction and Carpentry

In construction and carpentry, precision is critical to ensure that structures are built correctly and safely. The marks on a tape measure allow builders and carpenters to measure materials accurately, from the length of lumber to the placement of fixtures. Accurate measurements prevent material wastage, ensure structural integrity, and facilitate the seamless execution of complex building plans.

Tailoring and Fashion Design

Tailors and fashion designers rely on precise measurements to create well-fitting garments. The detailed marks on a tape measure enable accurate body measurements, pattern adjustments, and fabric cutting. This precision ensures that clothing items meet design specifications and fit clients comfortably, enhancing the overall quality of the final product.

DIY Home Improvement Projects

For DIY enthusiasts, the marks on a tape measure are indispensable tools for various home improvement tasks. Whether installing shelves, measuring for curtains, or laying flooring, accurate measurements ensure that installations are level, aligned, and proportionate. This reliability enhances the aesthetic appeal and functionality of home projects.

Engineering and Manufacturing

Engineers and manufacturers require precise measurements to design and produce components that fit together seamlessly. The clear and standardized marks on a tape measure facilitate the accurate sizing and alignment of parts, ensuring that assemblies meet stringent tolerances and perform as intended. This precision is vital in industries such as aerospace, automotive, and electronics.

Landscaping and Gardening

In landscaping and gardening, accurate measurements ensure that plants are spaced correctly, structures are level, and designs are executed as planned. The marks on a tape measure help gardeners and landscapers achieve balanced and aesthetically pleasing arrangements, contributing to the overall success of outdoor projects.

Innovative Uses of Tape Measure Marks

Marking Reference Points

Beyond measuring, the marks on a tape measure can serve as reference points for marking materials. For instance, when cutting wood or metal, the marks provide precise locations for cuts, ensuring consistency and accuracy across multiple pieces. This application is particularly useful in repetitive tasks where uniformity is essential.

Creating Templates and Patterns

Artists and craftspeople can use the marks on a tape measure to create templates and patterns for their projects. By leveraging the standardized increments, they can design intricate shapes and designs with consistent dimensions, enhancing the precision and quality of their work.

Educational Tools for Teaching Measurement

Teachers and educators can use tape measures as practical tools for teaching measurement concepts in mathematics and science classes. The clear and visible marks provide tangible examples of units and subdivisions, helping students grasp abstract measurement principles through hands-on learning.

Measuring Irregular Shapes

The flexibility of tape measures, combined with their detailed marks, makes them ideal for measuring irregular or curved shapes. By carefully aligning the tape along the contours of the object, users can capture accurate dimensions that would be challenging to obtain with rigid measuring tools.

Conclusion

Conclusion

In summary, the marks on a tape measure are integral to achieving accurate and reliable measurements in a multitude of applications. From construction and carpentry to tailoring and DIY projects, understanding and effectively utilizing these markings can significantly enhance the precision and quality of your work. As technology continues to evolve, the future of tape measure marks looks promising, promising even greater precision and functionality to meet the demands of modern measurement tasks. Whether you are a seasoned professional or a passionate hobbyist, mastering the use of the marks on a tape measure will undoubtedly contribute to your success and satisfaction in all your endeavors.