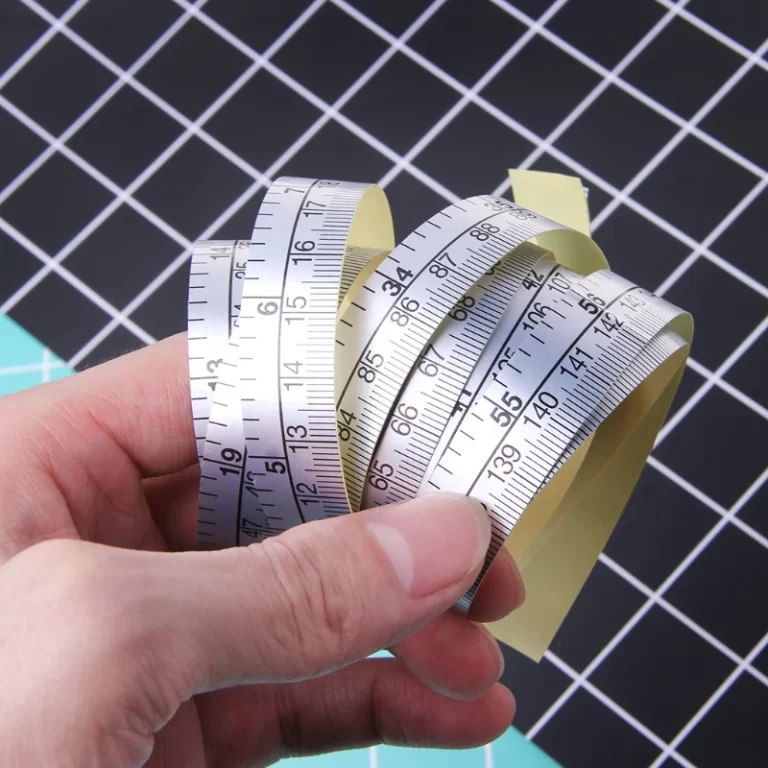

Tape Measure Increments: A Guide to Accurate Measurements

Accurate measurements are the cornerstone of successful projects, whether you’re involved in construction, tailoring, or any DIY endeavor. One fundamental tool that ensures precision is the tape measure, and understanding its tape measure increments is essential for reliable results. In this comprehensive guide, we will explore the intricacies of tape measure increments, how to read them correctly, and why they matter in achieving flawless measurements in your projects.

What Are Tape Measure Increments?

What Are Tape Measure Increments?

Tape measure increments refer to the divisions marked along the length of a tape measure, indicating specific units of measurement. These increments are typically represented in imperial units (inches and fractions) or metric units (centimeters and millimeters). Understanding these increments is crucial for accurate measurement, allowing users to determine precise lengths and distances required for their tasks.

The Importance of Accurate Increments

Accurate increments on a tape measure ensure that measurements are precise, thereby preventing errors that can lead to material waste, increased costs, and compromised project integrity. Whether you’re measuring fabric for a garment, cutting lumber for construction, or laying out tiles, reliable increments are essential for success.

Types of Increments

Tape measures come with various increment types to cater to different measurement needs. The most common types are imperial increments, metric increments, and dual-scale increments, each serving specific purposes based on the user’s requirements.

Imperial Increments

Imperial increments are based on the imperial system of measurement, commonly used in the United States and a few other countries. These increments are typically divided into inches and fractions of an inch, such as 1/16, 1/8, 1/4, and 1/2 inches. Understanding these fractions is vital for tasks that require precise measurements down to the fractional level.

Understanding Fractional Increments

Fractional increments allow for more detailed measurements within each inch. For example, a tape measure might mark every 1/16th of an inch, providing a high level of precision. This is particularly useful in applications like woodworking, where exact measurements can make a significant difference in the fit and finish of a project.

Metric Increments

Metric increments are based on the metric system, which is widely used around the world. These increments are marked in centimeters and millimeters, offering a straightforward and scalable measurement system. Metric tape measures typically feature increments of 1 millimeter, making them ideal for tasks that require fine precision.

Benefits of Metric Increments

Metric increments simplify calculations and conversions, especially for users familiar with the metric system. The consistent progression of centimeters and millimeters reduces the likelihood of errors, making it easier to achieve accurate measurements efficiently.

Dual-Scale Increments

Dual-scale tape measures feature both imperial and metric increments on the same tape, allowing users to switch between measurement systems seamlessly. This versatility is advantageous for projects that require working with both unit systems, providing flexibility and convenience.

Practical Applications of Dual-Scale Increments

Dual-scale tape measures are particularly useful for professionals who work in environments where both imperial and metric measurements are used. For instance, contractors and engineers often encounter specifications in different unit systems, and a dual-scale tape measure facilitates quick and accurate conversions without the need for additional tools.

How to Read Increments on a Tape Measure

How to Read Increments on a Tape Measure

Reading tape measure increments accurately is fundamental to obtaining precise measurements. By familiarizing yourself with the markings and understanding how to interpret them, you can enhance the accuracy of your measurements significantly.

Reading Imperial Increments

When reading imperial increments, start by identifying the largest unit, typically inches. Each inch is divided into smaller fractions, with each division representing a specific fraction of an inch. Here’s a step-by-step guide:

- Identify the Inch Mark: Locate the main inch markings, usually indicated by larger numbers or bold lines.

- Count the Fractions: Notice the smaller lines between each inch, representing fractions such as 1/16, 1/8, 1/4, and so on.

- Determine the Exact Fraction: Assess which fraction the measurement aligns with based on the length of the lines and their placement.

- Combine Units for Precision: For measurements requiring greater precision, combine the inch and fractional values accordingly.

Reading Metric Increments

Reading metric increments is often more straightforward due to the uniform progression of centimeters and millimeters. Here’s how to interpret them:

- Identify the Centimeter Mark: Locate the main centimeter markings, usually labeled with larger numbers or distinct lines.

- Count the Millimeters: Observe the smaller lines between each centimeter, each representing one millimeter.

- Determine the Millimeter Value: Identify the specific millimeter corresponding to the small lines.

- Combine Units for Exact Measurement: Add the millimeter value to the centimeter mark for precise measurements.

Utilizing Mixed Systems with Dual-Scale Increments

For dual-scale tape measures, it’s essential to understand how to switch between imperial and metric increments based on your measurement needs. Generally, one side of the tape will display imperial units while the other side shows metric units. Simply choose the scale that best suits your project requirements and proceed accordingly.

Common Increments on a Tape Measure and Their Uses

Different tape measure increments serve various purposes depending on the application. Understanding which increments to use in specific scenarios can enhance the accuracy and efficiency of your projects.

1/16 Inch Increments

1/16 inch increments are commonly used in woodworking and carpentry. They provide a high level of precision, allowing for accurate cuts and fittings. When working on detailed projects like furniture making or cabinetry, 1/16 inch increments help ensure that each component fits perfectly.

1/8 Inch Increments

1/8 inch increments are versatile and widely used in both construction and DIY projects. They offer a balance between precision and ease of use, making them suitable for tasks such as measuring walls, doors, and windows. The clear markings make it easy to read and interpret measurements quickly.

1/4 Inch Increments

1/4 inch increments are often used in larger scale projects where less precision is required. They are ideal for measuring broader spaces, such as flooring dimensions or large pieces of material. This increment provides sufficient accuracy for tasks that do not demand the fine detail of smaller fractions.

Centimeter and Millimeter Increments

Centimeter and millimeter increments are essential in applications requiring metric measurements. Centimeters are suitable for general measurements, while millimeters are used for fine-tuned precision. These increments are particularly useful in fields like engineering, design, and tailoring, where accurate measurements are critical.

Advantages of Understanding Increments on a Tape Measure

Advantages of Understanding Increments on a Tape Measure

Grasping the concept of tape measure increments offers numerous benefits, enhancing both the quality and efficiency of your work. Here are some key advantages:

Enhanced Measurement Accuracy

Knowing how to read and interpret tape measure increments accurately minimizes the risk of errors. This precision ensures that your measurements are reliable, leading to better outcomes in your projects.

Increased Efficiency

Familiarity with tape measure increments allows you to take measurements more quickly and confidently. This efficiency is especially beneficial in time-sensitive projects where speed and accuracy are paramount.

Versatility in Use

Understanding different increments enables you to tackle a wide range of projects, from simple DIY tasks to complex construction jobs. This versatility makes the tape measure an indispensable tool in your toolkit.

Reduced Material Waste

Accurate measurements prevent overestimation or underestimation of materials needed, reducing waste and saving costs. This conservation is not only economically beneficial but also environmentally friendly.

Tips for Maximizing the Use of Increments on a Tape Measure

To fully leverage the benefits of tape measure increments, consider the following tips that can enhance your measurement accuracy and overall project success.

Familiarize Yourself with the Scale

Before starting any project, take the time to familiarize yourself with the tape measure’s scale. Understanding the placement and meaning of each increment ensures that you can read measurements correctly without hesitation.

Use Markers for Precision

For measurements that require repeated precision, use markers or pens to indicate specific points. This practice helps maintain consistency and accuracy, especially in tasks that involve multiple measurements.

Practice Regularly

Like any skill, reading tape measure increments accurately improves with practice. Regularly measure objects of varying sizes and shapes to build your proficiency and confidence in using the tape measure.

Keep the Tape Measure Straight

To avoid measurement errors, ensure that the tape measure is held straight and taut against the object being measured. Avoid bending or twisting the tape, as this can distort the increments and lead to inaccurate readings.

Double-Check Critical Measurements

For critical measurements, it’s advisable to double-check by measuring twice. This redundancy helps verify accuracy and catches any potential mistakes before proceeding with the project.

Common Mistakes to Avoid with Increments on a Tape Measure

Avoiding common mistakes when reading tape measure increments can save time, materials, and frustration. Here are some pitfalls to watch out for:

Misreading the Scale

One of the most common mistakes is misreading the tape measure scale. Ensure that you are consistently reading the correct side of the tape and interpreting the increments accurately to prevent errors.

Ignoring Smaller Increments

Overlooking smaller increments can lead to significant inaccuracies, especially in projects requiring high precision. Pay attention to all increments, even the smallest ones, to ensure your measurements are as accurate as possible.

Failing to Align the Starting Point

Improper alignment of the tape measure’s starting point can result in incorrect measurements. Always ensure that the zero mark is precisely aligned with the edge of the object you are measuring.

Applying Uneven Pressure

Applying uneven pressure while measuring can cause the tape to bend or stretch, distorting the increments. Maintain consistent pressure to keep the tape measure straight and true to the scale.

Advanced Techniques for Reading Increments on a Tape Measure

Advanced Techniques for Reading Increments on a Tape Measure

For those looking to enhance their measurement skills further, advanced techniques can provide greater accuracy and efficiency when using tape measure increments.

Using the Shadow Method

The shadow method involves using the pointed end of the tape measure to cast a shadow that aligns with the desired increment. This technique is useful in low-light conditions or for achieving precise alignment without direct sight.

Zeroing the Tape Measure

Before taking a measurement, ensure that the tape measure is zeroed correctly. This practice involves confirming that the zero mark aligns with the starting point, eliminating any potential discrepancies.

Combining Multiple Measurements

For complex measurements, consider breaking them down into smaller sections and combining the results. This approach enhances accuracy by reducing the likelihood of cumulative errors.

Leveraging Technology

Modern tape measures often come with built-in digital displays that can simplify reading increments. Utilize these advanced features to streamline your measurement process and increase precision.

Choosing the Right Tape Measure Based on Increments

Selecting the appropriate tape measure for your needs involves considering the types of increments that best suit your projects. Here’s how to choose the right tape measure based on its increments:

For General Use

A standard tape measure with imperial increments, featuring 1/16 inch divisions, is ideal for general use. It provides the necessary precision for most DIY projects, construction tasks, and everyday measurements.

For Precision Work

For tasks that demand high precision, such as woodworking or tailoring, choose a tape measure with finer increments like 1/32 inch or millimeter markings. These detailed increments facilitate accurate measurements and meticulous craftsmanship.

For Versatile Applications

Dual-scale tape measures offer the versatility of both imperial and metric increments. This option is perfect for professionals who work with different measurement systems, providing flexibility and convenience in various project settings.

For Specialized Tasks

Certain projects may require specialized tape measures, such as those with extended lengths or reinforced cases. Consider the specific requirements of your tasks and select a tape measure with increments tailored to those needs.

The Role of Increments on a Tape Measure in Professional Fields

Understanding tape measure increments is not only beneficial for DIY enthusiasts but is also crucial in various professional fields. Here’s how different industries rely on precise tape measure increments:

Construction and Carpentry

In construction and carpentry, accurate measurements are vital for ensuring structural integrity and precise fittings. Tape measure increments allow professionals to measure spaces, materials, and components accurately, preventing costly mistakes and ensuring that projects are completed to specification.

Tailoring and Fashion Design

Tailors and fashion designers depend on precise measurements to create well-fitting garments. Tape measure increments enable detailed measurements of fabric and body dimensions, ensuring that each piece of clothing meets the desired specifications for fit and comfort.

Engineering and Design

Engineers and designers use tape measure increments to take precise measurements for plans and prototypes. Accurate measurements are essential for creating functional and reliable designs, as well as for communicating specifications effectively within teams.

Interior Design and Remodeling

Interior designers and remodelers rely on tape measure increments to assess spaces and plan layouts meticulously. Precise measurements ensure that furniture, fixtures, and decorative elements fit seamlessly within a space, enhancing both aesthetics and functionality.

Manufacturing and Fabrication

In manufacturing and fabrication, tape measure increments are crucial for quality control and assembly processes. Accurate measurements ensure that components are produced to exact specifications, facilitating the smooth operation of machinery and the integrity of finished products.

Conclusion

Conclusion

In the world of measurements, understanding tape measure increments is indispensable for achieving accuracy and precision in any project. From selecting the right type of tape measure to reading and maintaining the increments correctly, each aspect plays a crucial role in ensuring successful outcomes. By mastering the use of tape measure increments, you enhance your ability to execute projects with confidence and reliability, whether you’re a professional tradesperson or a passionate DIY enthusiast. Invest time in learning and applying the principles of tape measure increments, and witness the significant difference it makes in the quality and efficiency of your work.