How to Read a Tape Measure in Inches: A Beginner’s Guide

Accurate measurements are essential in a variety of tasks, from simple household projects to complex construction endeavors. Understanding how to read a tape measure in inches is a fundamental skill that ensures precision and efficiency in your work. Whether you are a DIY enthusiast, a professional builder, or someone who frequently engages in crafting, mastering this skill can significantly enhance the quality of your projects. This comprehensive guide will walk you through the process of reading a tape measure in inches, offering tips, techniques, and insights to help you achieve flawless measurements every time.

Understanding the Structure of a Tape Measure

Understanding the Structure of a Tape Measure

Before diving into the specifics of reading a tape measure in inches, it’s important to familiarize yourself with its structure. A standard tape measure consists of a metal or fiberglass blade that is marked with measurement units, housed within a durable casing. The blade retracts into the case, providing ease of storage and portability.

The Inch and Fractional System

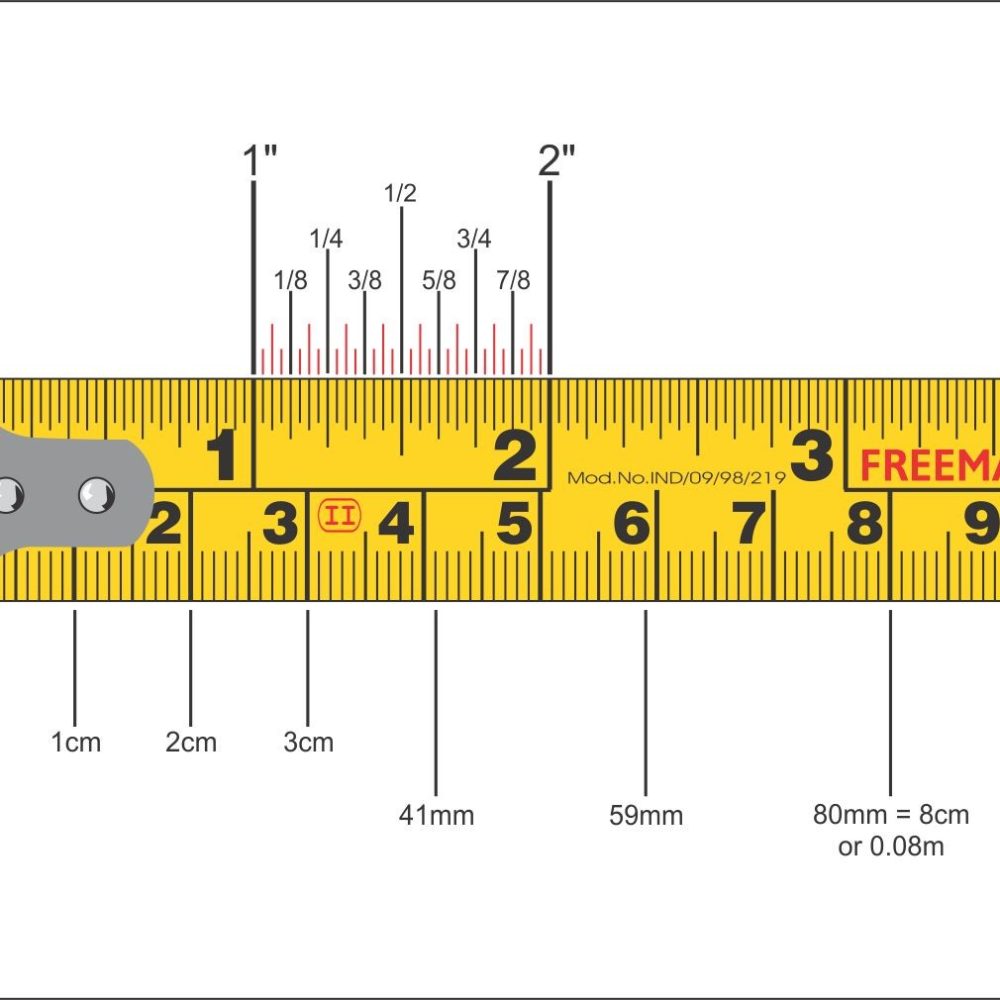

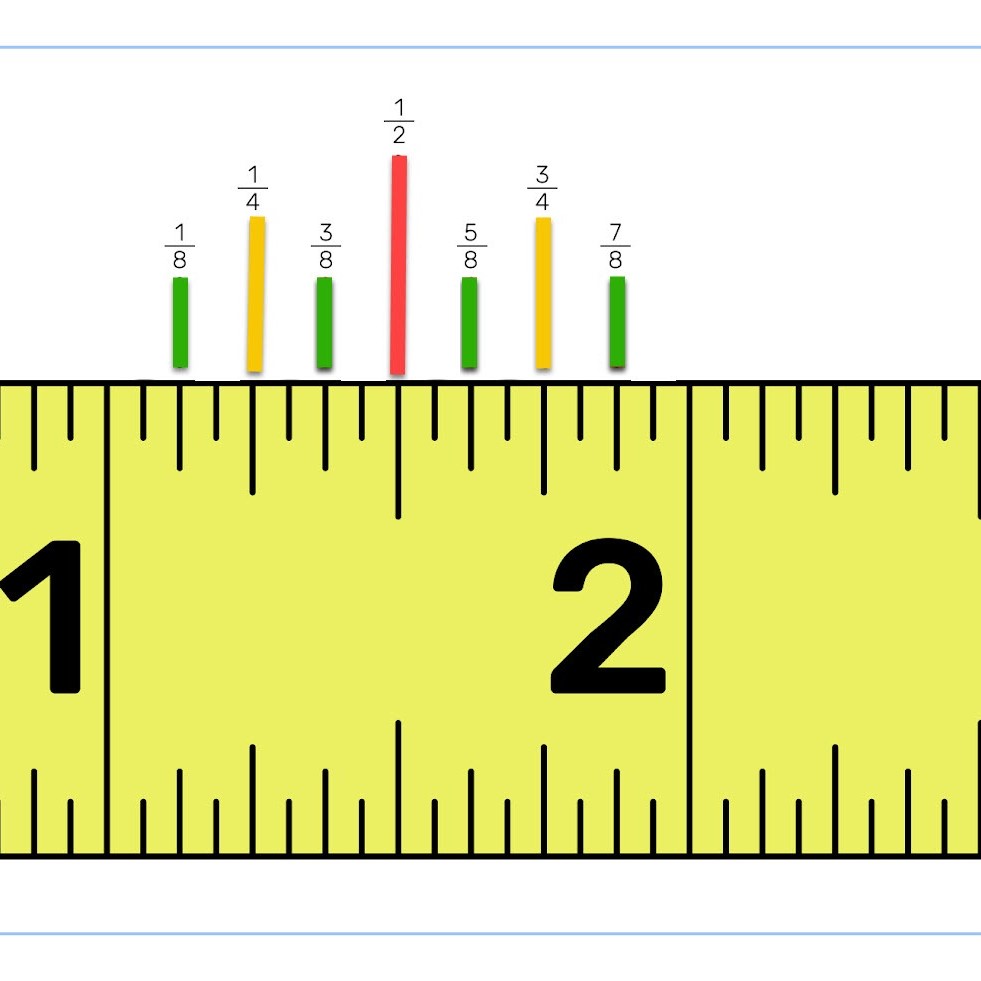

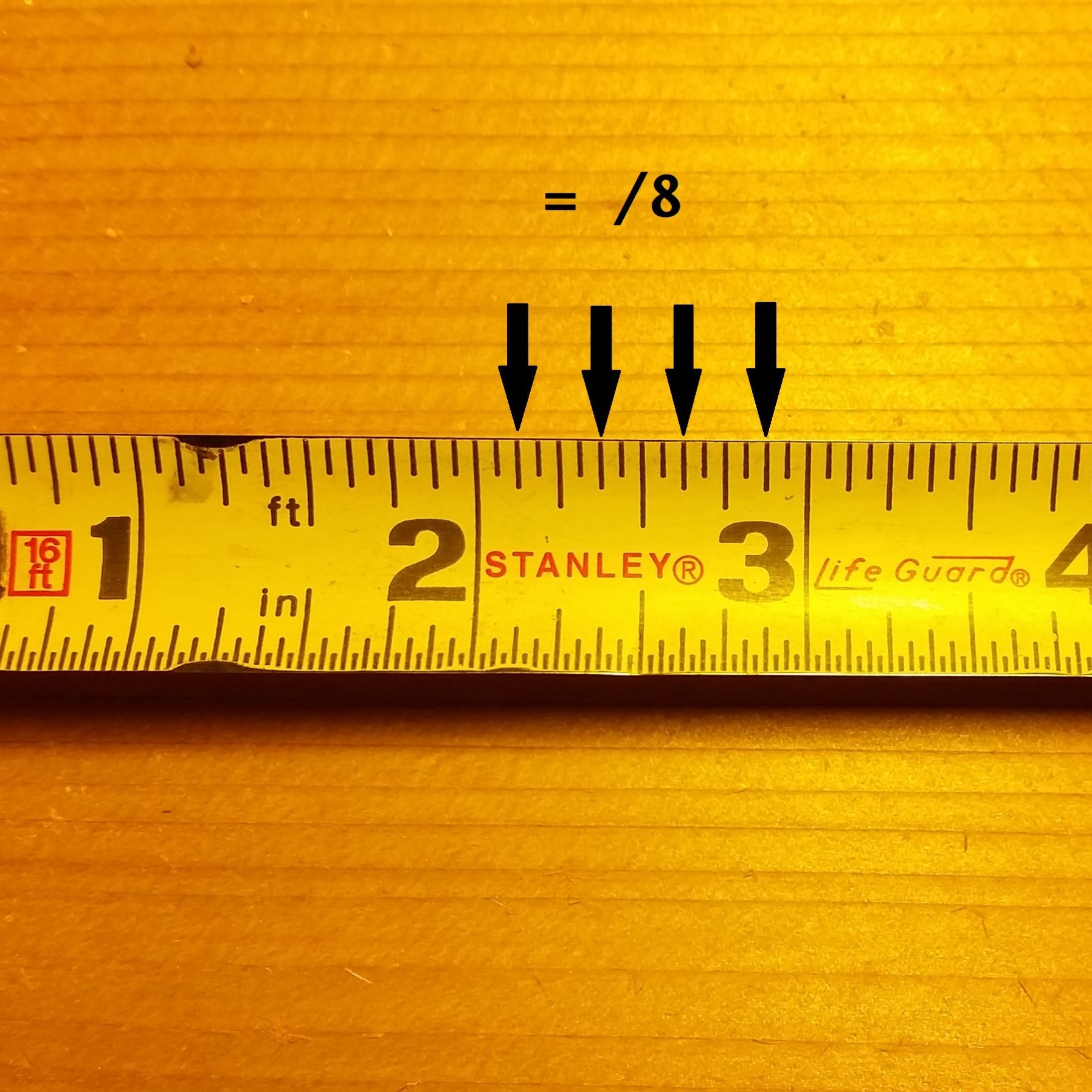

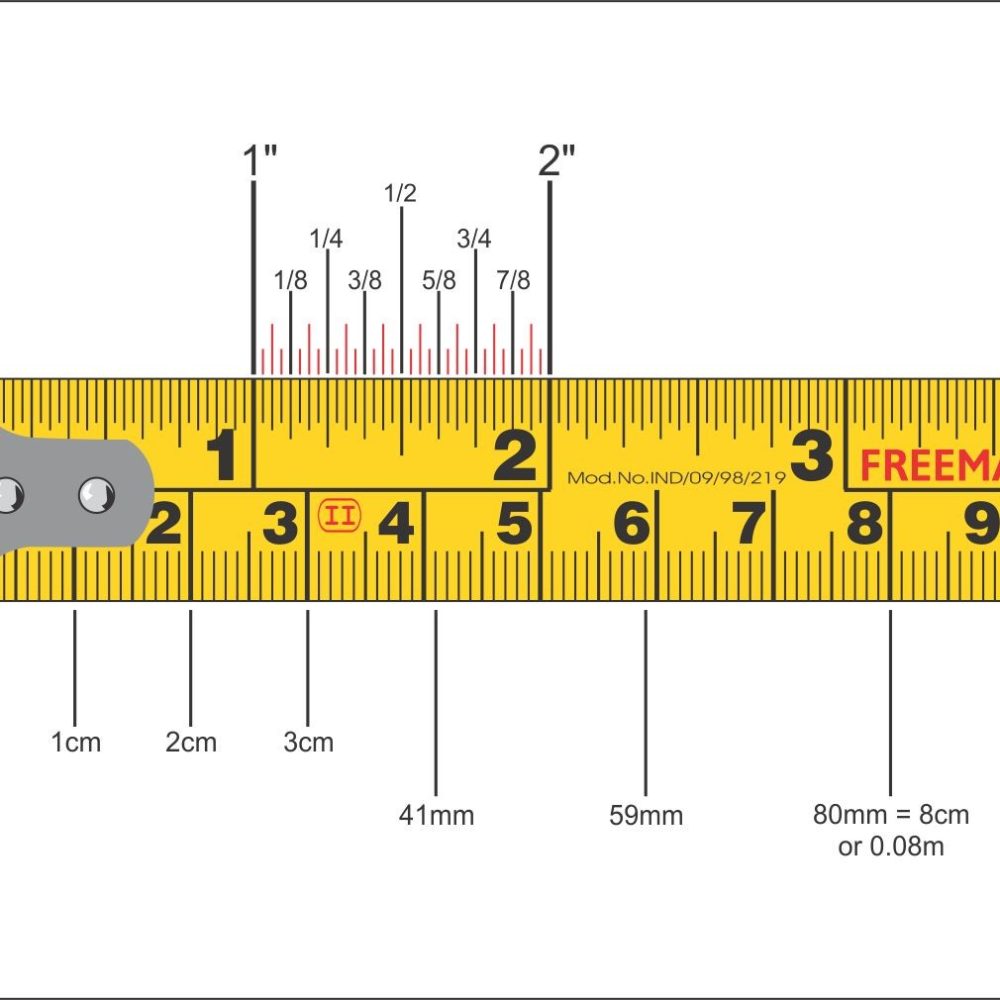

The inch is divided into smaller units to allow for precise measurements. Each inch is typically divided into halves, quarters, eighths, and sixteenths. This fractional system enables you to measure objects with fine accuracy. Understanding these fractions is crucial for interpreting the measurements correctly.

Major and Minor Marks

On a tape measure, the longer lines represent whole inches, while the shorter lines indicate fractional parts of an inch. For example, a line halfway between two whole inch marks denotes a half-inch (½”), a line a quarter of the way denotes a quarter-inch (¼”), and so on. Recognizing these marks is essential for accurately reading the tape.

How to Read a Tape Measure in Inches: Step-by-Step Guide

Mastering the ability to read a tape measure in inches involves a series of clear, methodical steps. By following this guide, you can ensure that your measurements are both precise and reliable.

1. Positioning the Tape Measure

Begin by holding the tape measure firmly at the zero mark. This mark is typically located at the very end of the tape and may feature a small metal hook. Ensure that the hook is securely anchored at the starting point of your measurement.

2. Extending the Tape

Pull the tape measure out towards the object or distance you intend to measure. Keep the tape straight and taut to avoid any bends or curves that could distort the measurement. As you extend the tape, the numbers will become more visible, allowing you to track the progress of your measurement.

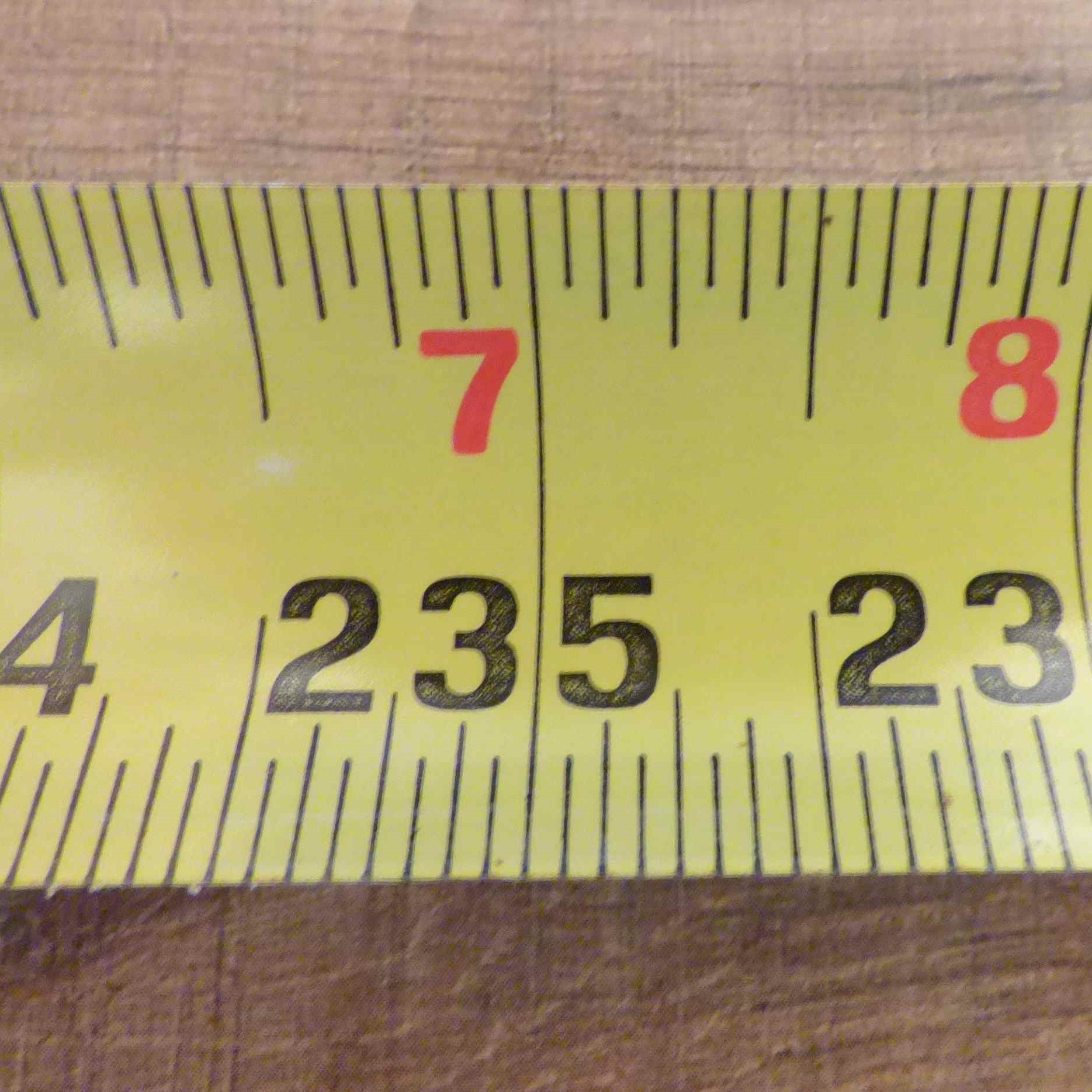

3. Identifying the Inch Marks

Look for the numbered inch marks along the tape. These are the primary indicators of measurement and are usually numbered at regular intervals. Each number represents one inch, providing the basic framework for your measurement.

4. Reading the Fractions

Between each whole inch mark, you’ll find smaller lines representing fractional inches. To accurately read a tape measure in inches, you must identify these fractions:

- Half-Inch (½”): The middle line between two whole inches.

- Quarter-Inch (¼”): The first and third lines between whole inches.

- Eighth-Inch (⅛”): The lines located between each quarter-inch mark.

- Sixteenth-Inch (1/16″): The smallest divisions, found between each eighth-inch mark.

By understanding these fractional divisions, you can achieve precise measurements down to the sixteenth of an inch.

5. Recording the Measurement

Once you have identified the correct inch and fractional mark, note the measurement carefully. It’s helpful to use both eyes to ensure accuracy and to double-check the reading if necessary. Recording the measurement promptly prevents errors that might occur if the tape shifts or moves.

6. Marking the Measurement

For added accuracy, especially in projects requiring precise cuts or placements, make a clear mark at the measured point. This can be done using a pencil, chalk, or any other suitable marking tool. Ensure that the mark is visible and accurately represents the measured length.

Tips for Accurate Measurements

Tips for Accurate Measurements

Achieving accurate measurements when reading a tape measure in inches requires attention to detail and the application of certain best practices. Here are some valuable tips to help you enhance your measurement accuracy:

Keep the Tape Straight

Always ensure that the tape measure remains straight and parallel to the surface you are measuring. Bending or angling the tape can lead to incorrect readings. For long measurements, support the tape at intervals to maintain its straightness.

Use Both Hands

Employing both hands to extend and hold the tape measure can provide greater control and stability. One hand can anchor the tape at the starting point, while the other can extend it to the desired measurement point. This technique reduces the risk of the tape slipping or moving during measurement.

Avoid Parallax Error

Parallax error occurs when the tape measure is not viewed directly from above, causing the measurement to appear distorted. To prevent this, position yourself directly in front of the measurement mark and keep your eyes level with the tape. This ensures that you are reading the measurement accurately without any visual distortion.

Lock the Tape in Place

Many tape measures come with a locking mechanism that allows the tape to stay in place once extended. Utilize this feature to maintain the tape’s position while taking your measurement. This prevents the tape from retracting accidentally, ensuring a stable and accurate reading.

Practice Regularly

Like any skill, reading a tape measure in inches becomes easier and more accurate with practice. Regularly practicing measurements on various objects and surfaces will help you become more confident and proficient in using a tape measure effectively.

Common Mistakes to Avoid

While reading a tape measure in inches is straightforward, several common mistakes can compromise measurement accuracy. Being aware of these pitfalls will help you avoid them and ensure reliable measurements.

Misreading the Markings

One of the most frequent errors is misreading the fractional markings on the tape. Take the time to carefully identify each fractional division and double-check your reading to avoid mistakes.

Not Keeping the Tape Taut

Allowing the tape measure to sag or bend can lead to inaccurate measurements. Always maintain tension in the tape to ensure that it stays straight and true to the measurement length.

Ignoring the Hook Thickness

The hook at the end of the tape measure is designed to account for its own thickness. When measuring external dimensions, the hook’s thickness is included, whereas, for internal dimensions, it is excluded. Failing to consider this can result in a slight discrepancy in your measurements.

Relying Solely on One Eye

Using only one eye to read the tape measure can lead to parallax error and misinterpretation of the measurement mark. Always use both eyes to align yourself properly with the measurement mark for a more accurate reading.

Advanced Techniques for Precision

For those seeking to elevate their measurement skills, several advanced techniques can enhance precision and efficiency when reading a tape measure in inches.

Measuring Odd Shapes and Angles

When dealing with irregular shapes or angles, using a tape measure effectively requires a bit more finesse. To measure an angle, extend the tape measure along the angle’s edge, ensuring that it remains straight and aligned with the surface. For curved surfaces, use a flexible tape measure and follow the contour closely to capture the accurate length.

Utilizing Measurement Aids

Incorporating tools such as measurement guides or templates can assist in achieving more accurate measurements. These aids provide a reference point that helps maintain consistent tape positioning, reducing the likelihood of errors.

Double-Checking Measurements

For critical measurements, it’s advisable to take multiple readings and compare them. This redundancy ensures that any minor discrepancies are caught and corrected, enhancing overall measurement reliability.

Combining Digital and Traditional Methods

Leveraging both digital tools and traditional tape measures can provide a comprehensive approach to measurement accuracy. Digital tape measures offer precise readings with digital displays, while traditional tapes offer versatility and ease of use in various scenarios. Combining these methods can enhance your measurement capabilities.

Maintaining Your Tape Measure

Maintaining Your Tape Measure

Proper maintenance of your tape measure is essential for ensuring its longevity and accuracy. Regular upkeep prevents wear and tear, allowing the tool to function optimally over time.

Cleaning the Tape

After use, wipe the tape blade with a clean cloth to remove dirt, debris, and moisture. This practice helps prevent rusting and sticking, ensuring smooth retraction and accurate measurements in future use.

Inspecting for Damage

Regularly inspect your tape measure for signs of damage, such as kinks, bends, or broken hooks. Damaged tapes can lead to unreliable measurements and should be repaired or replaced promptly to maintain precision.

Storing Properly

Store your tape measure in a dry, cool place, preferably in its case, to protect it from moisture and extreme temperatures. Proper storage prevents rusting and other forms of deterioration that can affect the tape’s functionality.

Lubricating the Blade

Occasionally lubricate the tape blade with a light oil to ensure smooth retraction and reduce friction. This maintenance step can prolong the life of your tape measure and maintain its accuracy.

Practical Applications of Accurate Tape Measurement

Understanding how to read a tape measure in inches is not just about precision; it directly impacts the success of your projects. Here are some practical applications where accurate tape measurement is crucial.

Home Improvement Projects

Whether you’re installing shelves, hanging pictures, or measuring spaces for furniture, accurate tape measurements ensure that everything fits perfectly. Precision in measurements can prevent costly mistakes and enhance the overall aesthetic of your home.

Construction and Carpentry

In construction and carpentry, precise measurements are non-negotiable. From cutting lumber to fitting windows and doors, accurate tape measurements ensure structural integrity and alignment, which are essential for building safe and functional structures.

Sewing and Tailoring

For those involved in sewing and tailoring, knowing how to read a tape measure in inches is vital for creating garments that fit well. Accurate measurements ensure that clothing items conform to body dimensions, providing comfort and a professional finish.

Landscaping and Gardening

Accurate measurements are also important in landscaping and gardening. Whether you’re planning the layout of a garden bed, installing a fence, or laying out pathways, precise measurements contribute to the overall functionality and appearance of your outdoor space.

Enhancing Your Measurement Skills

Enhancing Your Measurement Skills

Improving your ability to read a tape measure in inches involves continuous learning and practice. Here are some strategies to enhance your measurement skills further.

Educational Resources

Utilize books, online tutorials, and instructional videos that focus on measurement techniques. These resources can provide additional insights and tips that can refine your skills and expand your knowledge.

Hands-On Practice

Engage in hands-on projects that require precise measurements. Practical experience is invaluable in developing a keen sense of measurement accuracy and building confidence in your abilities.

Seeking Feedback

Collaborate with others who have expertise in measurement and seek their feedback. Constructive criticism can help identify areas for improvement and provide new perspectives on measurement techniques.

Attending Workshops

Participate in workshops or training sessions dedicated to measurement and measurement tools. These events offer opportunities to learn from professionals and gain hands-on experience with different types of tape measures.

The Role of Accuracy in Project Success

Accurate measurements play a pivotal role in the success of any project. Whether you are building, crafting, or renovating, precision in measuring ensures that all components fit together seamlessly, reducing the risk of errors and rework.

Cost Efficiency

Accurate measurements can save you money by minimizing material waste and preventing the need for costly corrections. Precise planning and measuring ensure that resources are used efficiently, contributing to the overall cost-effectiveness of your projects.

Time Management

When measurements are accurate from the start, projects proceed more smoothly and swiftly. Avoiding measurement errors reduces delays and accelerates project timelines, allowing you to achieve your goals more efficiently.

Quality Assurance

High-quality results are a direct outcome of accurate measurements. Whether it’s the structural integrity of a building or the fit of a tailored garment, precision in measurement underpins the overall quality and functionality of the final product.

Leveraging Technology for Enhanced Measurement

In today’s digital age, technology offers tools that complement traditional tape measures, enhancing measurement accuracy and ease of use.

Digital Tape Measures

Digital tape measures provide precise measurements with the added benefit of digital displays. These devices often include features such as memory storage, unit conversion, and automatic locking, streamlining the measurement process and reducing the potential for human error.

Laser Distance Meters

Laser distance meters offer quick and accurate measurements without the need for a physical tape. They are especially useful for measuring large distances and hard-to-reach areas, providing digital readings that minimize the risk of parallax error.

Mobile Measurement Apps

Several mobile applications simulate tape measure functionalities, allowing users to take measurements using their smartphones. While not always as accurate as physical tapes, these apps can be useful for approximate measurements and quick assessments in situations where carrying a tape measure is inconvenient.

Incorporating Best Practices into Your Workflow

Integrating accurate tape measurement techniques into your daily workflow can enhance your efficiency and the overall quality of your work.

Planning and Preparation

Before starting any project, review your tape measure and ensure you understand the measurement requirements. Proper planning and preparation help you approach each task with precision and confidence, reducing the likelihood of errors.

Organizing Your Tools

Keep your tape measure and other measuring tools organized and easily accessible. An organized workspace minimizes time spent searching for tools and ensures that you can quickly retrieve them when needed, maintaining the flow of your work.

Continuous Improvement

Strive for continuous improvement by regularly assessing your measurement techniques and seeking ways to enhance them. Staying updated with the latest measurement tools and methods ensures that you remain proficient and adaptable in your approach.

Conclusion

Conclusion

Understanding how to read a tape measure in inches is a fundamental skill that underpins the success of numerous projects across various fields. By mastering this skill, you ensure that your measurements are accurate, reliable, and efficient, leading to superior results in your work. This comprehensive guide has provided you with the necessary knowledge and techniques to read a tape measure in inches confidently and accurately.

From familiarizing yourself with the tape measure’s structure to applying advanced measurement techniques and leveraging technology, each aspect plays a crucial role in enhancing your measurement accuracy. Additionally, maintaining your tape measure and incorporating best practices into your workflow ensures that your tool remains reliable and your skills continue to improve.

Whether you are undertaking simple household tasks or engaging in complex construction projects, mastering how to read a tape measure in inches equips you with the precision needed to achieve excellence. Embrace these practices to elevate the quality of your work, prevent common measurement errors, and ensure that every project you undertake is executed with the highest level of accuracy and professionalism.