Understanding 7/8 on a Tape Measure for Your DIY Needs

When engaging in projects that demand precise measurements, every fraction of an inch matters. One such crucial measurement is the 7/8 on a tape measure, a mark that plays a significant role in ensuring accuracy in various applications. Whether you are a DIY enthusiast, a professional carpenter, or someone involved in tailoring, comprehending how to effectively use the 7/8-inch mark on a tape measure can make a substantial difference in the quality and precision of your work. This comprehensive guide explores the significance of the 7/8-inch mark, its practical applications, techniques for accurate measurement, and tips to avoid common mistakes, thereby enhancing your measurement skills and project outcomes.

The Significance of the 7/8 Inch Mark on a Tape Measure

The Significance of the 7/8 Inch Mark on a Tape Measure

Understanding Fractional Measurements

Fractional measurements, such as the 7/8 inch, are integral to achieving exactness in various tasks. Unlike whole numbers, fractions allow for finer adjustments, which are often necessary in detailed work. The 7/8 on a tape measure represents a fraction that is just one-eighth of an inch short of a full inch, providing a high degree of precision.

Why the 7/8 Inch Mark Matters

The 7/8-inch mark is particularly important in applications where slight deviations can lead to significant issues. For instance, in woodworking, precise measurements ensure that joints fit seamlessly, enhancing the structural integrity and aesthetic appeal of the finished product. Similarly, in tailoring, accurate fractional measurements guarantee that garments fit perfectly, offering both comfort and style.

Practical Applications of the 7/8 Inch Mark

Woodworking and Carpentry

In woodworking, the 7/8-inch measurement is often used for creating joints, fitting pieces together, and ensuring the accuracy of cuts. For example, when crafting a dovetail joint, the 7/8-inch mark can help in aligning the pieces precisely, preventing gaps and ensuring a sturdy connection. Additionally, when installing trim or molding, the 7/8-inch mark assists in achieving uniformity and a professional finish.

Tailoring and Sewing

For tailors and sewers, the 7/8 inch plays a vital role in pattern making and fabric cutting. Accurate measurements are essential to ensure that garments fit the wearer perfectly. The 7/8-inch mark helps in making fine adjustments to patterns, especially around areas like sleeves, collars, and hems, where precision is paramount for a polished look.

DIY Projects and Home Improvement

In DIY projects, whether you are building furniture, installing shelves, or mounting fixtures, the 7/8-inch mark ensures that your work is precise and level. For instance, when installing a shelf, using the 7/8-inch mark can help in ensuring that the brackets are evenly spaced and securely attached, preventing the shelf from wobbling or becoming misaligned over time.

Plumbing and Electrical Work

For professionals in plumbing and electrical fields, the 7/8-inch measurement is crucial for tasks such as fitting pipes, wiring channels, and ensuring that components align correctly. Precise measurements prevent leaks, electrical faults, and other issues that can arise from inaccurate installations.

Techniques for Accurate Measurement Using the 7/8 Inch Mark

Techniques for Accurate Measurement Using the 7/8 Inch Mark

Proper Tape Measure Handling

To effectively utilize the 7/8-inch mark, it is essential to handle the tape measure correctly. Begin by ensuring that the tape is flat against the surface you are measuring. This position prevents the tape from bending or curving, which can lead to inaccurate readings. Additionally, always hold the tape measure firmly but not too tightly, allowing it to move smoothly as needed.

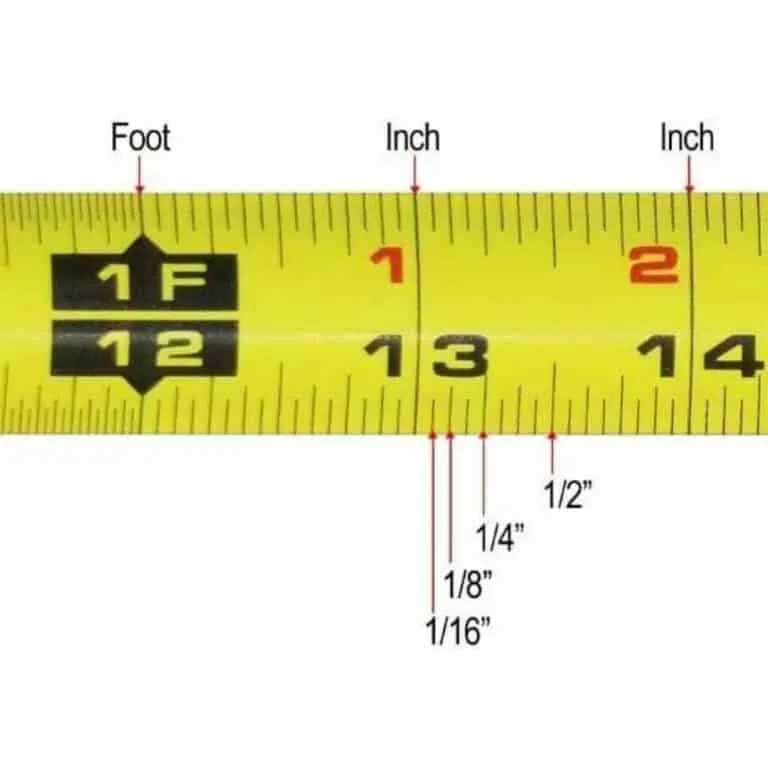

Reading the Tape Measure Correctly

Reading the tape measure accurately involves understanding the placement of the 7/8-inch mark in relation to the whole and fractional inches. Typically, each inch is divided into eighths, and the 7/8-inch mark is the seventh division from the left on a standard tape measure. To read it correctly, identify the whole inch closest to your measurement point, then count seven divisions to reach the 7/8 mark.

Marking and Recording Measurements

Once you have identified the 7/8-inch mark, use a fine-tip pencil or a marking tool to denote the exact measurement. This precision is crucial when transferring the measurement to your workpiece. For example, when cutting a piece of wood, accurately marking the 7/8-inch point ensures that your cut aligns with the intended design, preventing mistakes that could compromise the project’s integrity.

Double-Checking Measurements

To guarantee accuracy, always double-check your measurements. Measure twice and cut once is a common adage in construction and woodworking for this reason. By verifying the 7/8-inch mark, you can catch any errors before they affect your project, saving time and materials in the long run.

Common Mistakes and How to Avoid Them

Misreading the Tape Measure

One of the most common mistakes is misreading the tape measure, particularly the fractional marks. To avoid this, take time to familiarize yourself with the tape’s divisions and practice reading them accurately. Paying close attention to the 7/8-inch mark can prevent significant errors in your measurements.

Not Securing the Tape Measure Properly

Failing to secure the tape measure correctly can result in movement during measurement, leading to inaccuracies. Always anchor the tape measure at the starting point and hold it steady while taking the measurement. Using measurement aids, such as clamps or adhesive tape, can help keep the tape in place, especially for longer measurements.

Rushing the Measurement Process

Rushing through measurements increases the likelihood of mistakes. Instead, take your time to ensure each measurement is precise. Carefully align the 7/8-inch mark with your reference point and verify it before proceeding with your project.

Ignoring the Tape Measure’s Flexibility

Tape measures are designed to be flexible, allowing them to contour around objects and surfaces. Ignoring this flexibility and forcing the tape to stay straight can cause it to bend or kink, resulting in inaccurate measurements. Let the tape measure follow the natural curves of the surface to maintain precision.

Tools and Accessories to Enhance Measurement Accuracy

Magnetic Tape Measures

Magnetic tape measures feature a magnet at the end of the tape, making it easier to hold the tape in place when taking measurements on metal surfaces. This feature is particularly useful in plumbing and electrical work, where precise measurements are critical.

Digital Tape Measures

Digital tape measures offer enhanced accuracy by providing digital readouts of measurements. Some models can display measurements in multiple units and store past measurements for easy reference. The integration of technology simplifies the measurement process and reduces the chances of human error.

Measuring Guides and Templates

Using measuring guides or templates can help in transferring the 7/8-inch measurement accurately to your workpiece. These tools provide a stable surface for marking and ensure that your measurements remain consistent across multiple points.

Protective Cases and Holders

Protecting your tape measure from damage extends its lifespan and maintains its accuracy. Using protective cases or holders prevents the tape from bending, kinking, or getting scratched, ensuring that the 7/8-inch mark and other measurements remain clear and readable.

Maintaining Your Tape Measure for Longevity

Maintaining Your Tape Measure for Longevity

Regular Cleaning

Keeping your tape measure clean ensures that the measurement markings, including the 7/8-inch mark, remain visible and accurate. Wipe the tape regularly with a dry cloth to remove dust and debris. Avoid using harsh chemicals that can damage the tape’s surface.

Proper Storage

Store your tape measure in a cool, dry place away from direct sunlight. Extreme temperatures and humidity can cause the tape to warp or the markings to fade. Using a protective case or hanger can prevent tangling and prolong the tape’s life.

Inspecting for Wear and Tear

Regularly inspect your tape measure for signs of wear and tear, such as frayed edges, bent tape, or faded markings. Addressing these issues promptly by repairing or replacing the tape measure ensures that it remains a reliable tool for accurate measurements.

Calibration Checks

For digital tape measures, periodic calibration checks ensure that the device remains accurate. Follow the manufacturer’s instructions for calibration and maintenance to keep the digital features functioning correctly.

Advanced Techniques for Using the 7/8 Inch Mark

Utilizing the 7/8 Inch in Complex Designs

In intricate designs, such as furniture making or detailed carpentry, the 7/8-inch mark helps in creating precise joints and fittings. For example, when crafting a drawer frame, using the 7/8-inch measurement ensures that the joints align perfectly, contributing to the drawer’s smooth operation and overall durability.

Precision in Laminations and Layering

When working with laminations or layering materials, the 7/8-inch mark can guide the exact placement of each layer. This precision prevents unevenness and ensures that the final product maintains structural integrity and aesthetic consistency.

Incorporating the 7/8 Inch in Measurement Systems

Incorporating the 7/8-inch mark into your personal or project-specific measurement systems can streamline your workflow. By standardizing this measurement point, you can create templates and guides that facilitate quick and accurate measurements across various tasks.

Enhancing Project Outcomes with the 7/8 Inch Measurement

Achieving Consistency and Uniformity

Using the 7/8-inch mark consistently across different measurements ensures uniformity in your projects. Whether you are building multiple pieces of furniture or sewing several garments, maintaining consistent measurements leads to a cohesive and professional finish.

Reducing Material Waste

Accurate measurements using the 7/8-inch mark help in minimizing material waste. By ensuring that each cut or alteration is precise, you reduce the likelihood of errors that necessitate reworking or discarding materials, leading to cost savings and more efficient use of resources.

Improving Structural Integrity

In construction and carpentry, precise measurements are essential for the structural integrity of the finished product. The 7/8-inch mark assists in aligning components accurately, ensuring that joints are secure and the overall structure is sound and durable.

Enhancing Aesthetic Appeal

Precision in measurements directly impacts the aesthetic appeal of a project. Whether it’s the seamless alignment of fabric in tailoring or the flawless joinery in woodworking, the 7/8-inch mark contributes to a polished and professional appearance.

Overcoming Challenges with the 7/8 Inch Measurement

Overcoming Challenges with the 7/8 Inch Measurement

Dealing with Curved Surfaces

Measuring curved surfaces can be challenging, but the flexibility of the tape measure allows you to follow curves accurately. Utilize the 7/8-inch mark by ensuring the tape conforms smoothly to the surface, maintaining consistent tension to avoid stretching or sagging.

Handling Hard-to-Reach Areas

In projects requiring measurements in tight or hard-to-reach areas, the 7/8-inch mark remains accessible with the right techniques. Use smaller tape measures or measuring sticks to reach difficult spots, ensuring that the 7/8-inch mark is still accurately identified and utilized.

Maintaining Measurement Accuracy in Varying Conditions

Environmental factors such as temperature and humidity can affect tape measure accuracy. To maintain precision, ensure that the tape measure is stored properly and used in stable conditions. Additionally, regularly calibrate digital tape measures to account for any potential discrepancies caused by environmental changes.

Adapting to Different Tape Measure Types

Different types of tape measures, such as fiberglass, cloth, or digital, may display the 7/8-inch mark differently. Familiarize yourself with the specific tape measure you are using, understanding how the 7/8-inch mark is presented and ensuring that it is clear and easy to read in your preferred format.

Future Trends and Innovations in Tape Measures

Future Trends and Innovations in Tape Measures

Enhanced Visibility and Markings

Future tape measures are likely to feature improved visibility for fractional marks like the 7/8 inch. Innovations such as larger markings, contrasting colors, and luminescent inks can make the 7/8-inch mark more prominent, enhancing ease of use in various lighting conditions.

Integration with Smart Technology

The integration of smart technology into tape measures promises to revolutionize how measurements are taken and recorded. Features such as Bluetooth connectivity, digital displays, and mobile app integration can provide real-time measurement data, making it easier to track and utilize the 7/8-inch mark in complex projects.

Ergonomic Designs

Ergonomic designs that enhance comfort and ease of use are becoming more prevalent in tape measures. Improved grip handles, lightweight materials, and streamlined tape guides can make it easier to handle the tape measure, ensuring that the 7/8-inch mark is accessible and easy to read during extended use.

Sustainable Materials

As sustainability becomes increasingly important, tape measure manufacturers are exploring eco-friendly materials and production methods. Using recycled plastics, non-toxic inks, and sustainable manufacturing practices ensures that tape measures remain reliable tools without negatively impacting the environment.

Conclusion

Mastering the use of the 7/8 on a tape measure is essential for achieving precision and excellence in a wide range of projects. From woodworking and tailoring to DIY home improvements and professional construction, the 7/8-inch mark serves as a critical reference point for accurate measurements. By understanding its significance, applying proper measurement techniques, and utilizing the right tools and accessories, you can enhance the quality and reliability of your work. Furthermore, avoiding common mistakes and maintaining your tape measure ensures that the 7/8-inch mark remains a dependable guide in all your endeavors. Embrace the precision that the 7/8-inch measurement offers, and watch as your projects benefit from the enhanced accuracy and professionalism it brings.