5/8 on a Tape Measure: Measurements and Applications

Precision is paramount in various tasks, from construction and tailoring to DIY projects and everyday measurements. Among the many markings on a tape measure, the 5/8 on a tape measure stands out as a crucial point for accuracy and consistency. Whether you’re a professional tradesperson or a hobbyist, comprehending the significance of the 5/8 mark can enhance your measurement skills and ensure your projects are executed flawlessly. This comprehensive guide delves into the intricacies of the 5/8 on a tape measure, exploring its applications, importance, and tips for effective use.

Practical Applications of 5/8 on a Measure Tape

Practical Applications of 5/8 on a Measure Tape

The versatility of the 5/8 on a tape measure is evident in its wide range of applications across different fields. Let’s explore some of the most common uses and how they contribute to successful outcomes.

Carpentry and Woodworking

In carpentry, the 5/8-inch measurement is indispensable for various tasks. For example, when installing cabinets, the 5/8-inch mark ensures that hinges are positioned correctly, providing the necessary clearance for doors to open and close without obstruction. Moreover, when building furniture or other wooden structures, accurate 5/8-inch measurements can determine the placement of joints, nails, and screws, contributing to the overall sturdiness and durability of the piece.

Construction and Framing

The construction industry relies heavily on precise measurements to ensure that buildings are safe and structurally sound. The 5/8 on a tape measure is particularly useful for framing walls, where it can help in spacing studs evenly and aligning various components correctly. Additionally, it aids in measuring openings for windows and doors, ensuring that these installations fit perfectly within the framed structure.

Sewing and Tailoring

In sewing and tailoring, the 5/8-inch mark is crucial for tasks such as hemming, seam allowances, and pattern alignment. Accurate measurements at this scale ensure that garments fit well and maintain their intended shape and size. Furthermore, using the 5/8-inch measurement can help in creating consistent seams and hems, which are essential for professional-looking finished products.

DIY Projects and Home Improvement

For DIY enthusiasts, the 5/8 on a tape measure is a valuable tool for a multitude of projects. Whether you’re hanging pictures, installing shelves, or building simple furniture, accurate 5/8-inch measurements can make the difference between a successful project and a frustrating one. By using this specific measurement as a reference point, you can ensure that all elements of your project are aligned and proportionate.

Tips for Using 5/8 on a Measure Tape Effectively

To maximize the utility of the 5/8 on a tape measure, it’s essential to employ effective measurement techniques and best practices. Here are some tips to help you use this specific mark accurately and efficiently.

Ensure Tape Measure Accuracy

Firstly, always make sure that your tape measure is in good condition and free from damage. A worn or damaged tape can lead to inaccurate measurements, compromising the quality of your work. Regularly inspect the tape for signs of wear, such as fraying or stretching, and replace it if necessary to maintain precision.

Utilize Consistent Measurement Techniques

Moreover, adopting consistent measurement techniques is vital for accuracy. When using the 5/8-inch mark, ensure that the tape measure is held straight and taut against the surface being measured. Avoid bending or twisting the tape, as this can distort the measurement and lead to errors.

Additionally, always start measuring from the tape measure’s zero point, as starting from a different point can result in inaccurate measurements. Consistently using the zero point ensures that all measurements are reliable and comparable.

Marking and Notching

Furthermore, when working with the 5/8-inch measurement, it can be helpful to make clear marks or notches at this point. Using a pencil or chalk, mark the exact 5/8-inch location to create a visible reference. This practice is especially useful when transferring measurements to another surface or when aligning multiple pieces.

Notching involves creating small indentations or cuts at the 5/8-inch mark, which can serve as guides for placement. This technique enhances precision and makes it easier to replicate measurements accurately across different parts of your project.

Double-Checking Measurements

In addition, always double-check your measurements to ensure accuracy. After marking the 5/8-inch point, measure it again to confirm that it aligns with the intended dimension. Verifying measurements helps catch any potential errors early, preventing mistakes from propagating throughout your project.

Double-checking is particularly important in complex projects where multiple measurements intersect or where precision is critical for the overall success of the work.

Using Proper Tools and Accessories

Lastly, complement your tape measure with other measurement tools and accessories to enhance accuracy. For example, using a measuring jig or a square can help maintain consistent angles and alignments when working with the 5/8-inch measurement. Additionally, clamps and vices can hold materials firmly in place, reducing movement and ensuring that measurements remain steady and precise.

Common Mistakes to Avoid with 5/8 on a Measure Tape

Common Mistakes to Avoid with 5/8 on a Measure Tape

Even with the best intentions, it’s easy to make mistakes when working with the 5/8 on a tape measure. Being aware of common errors and knowing how to avoid them can significantly improve the accuracy and reliability of your measurements.

Misreading the Tape

One of the most frequent mistakes is misreading the tape measure, especially when dealing with fractional measurements like 5/8 inches. To avoid this, take your time to carefully identify the correct mark. Practice reading the tape at eye level to prevent parallax errors, which occur when the measurement appears different due to the angle of viewing.

Additionally, familiarize yourself with the tape measure’s markings by practicing with various measurements. The more comfortable you become with the tape, the less likely you are to misread critical measurements like the 5/8-inch mark.

Not Keeping the Tape Straight

Another common error is not keeping the tape measure straight and taut while measuring. Allowing the tape to sag or bend can lead to inaccurate measurements. To prevent this, hold the tape measure firmly against the surface and use your other hand to guide it straight. If necessary, use a second person to help hold the tape in place for added stability.

Maintaining a straight and taut tape ensures that the measurement remains true and free from distortions that can compromise the integrity of your project.

Ignoring Material Flexibility

Materials often have inherent flexibility, which can affect measurements. Ignoring this flexibility, especially when working with soft or bendable materials, can lead to inaccurate 5/8-inch measurements. To counteract this, measure from the material’s stable edge or use a straightedge to hold the material firmly in place while measuring.

Understanding how different materials behave and adjusting your measurement techniques accordingly is crucial for achieving precise results.

Rushing the Measurement Process

Rushing through the measurement process is another mistake that can lead to errors. Taking the time to measure carefully and methodically, especially when dealing with critical measurements like 5/8 inches, ensures greater accuracy. Develop a habit of pausing to confirm each measurement before moving on to the next step in your project.

Patience and attention to detail are key factors in avoiding measurement mistakes and achieving high-quality outcomes.

Failing to Account for Tool Limitations

Lastly, failing to account for the limitations of your tape measure can result in inaccuracies. Not all tape measures are created equal, and some may have less precise markings or shorter overall lengths, which can affect the accuracy of the 5/8-inch measurement. Choose a high-quality tape measure with clear, precise markings and a durable construction to minimize the risk of measurement errors.

Investing in a reliable tape measure ensures that your measurements, including the critical 5/8-inch mark, remain accurate and trustworthy throughout your projects.

Advanced Techniques Involving 5/8 on a Measure Tape

Advanced Techniques Involving 5/8 on a Measure Tape

For those looking to elevate their measurement skills, mastering advanced techniques involving the 5/8 on a tape measure can greatly enhance your efficiency and precision. These techniques are particularly useful in specialized applications and complex projects.

Fractional Measurement Conversion

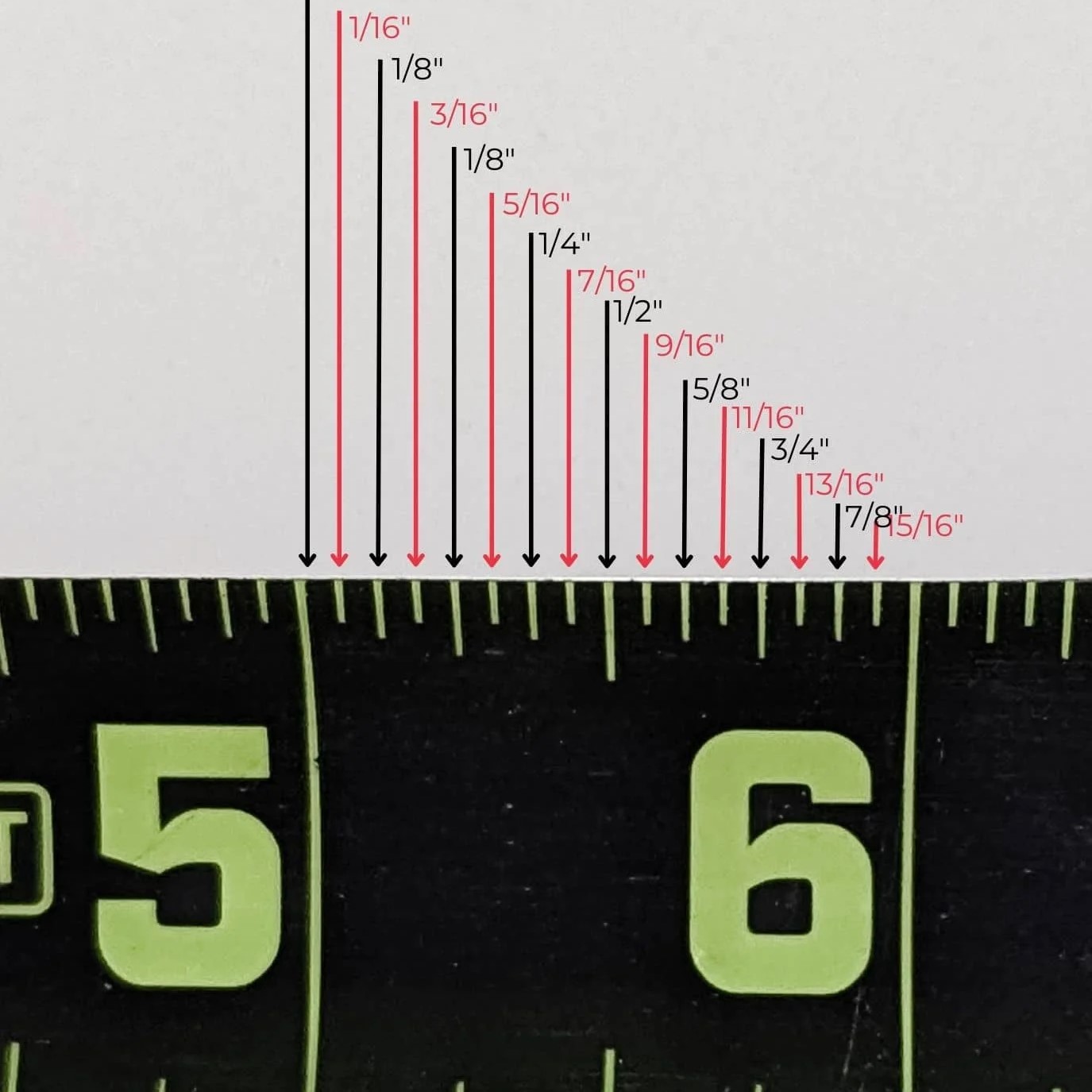

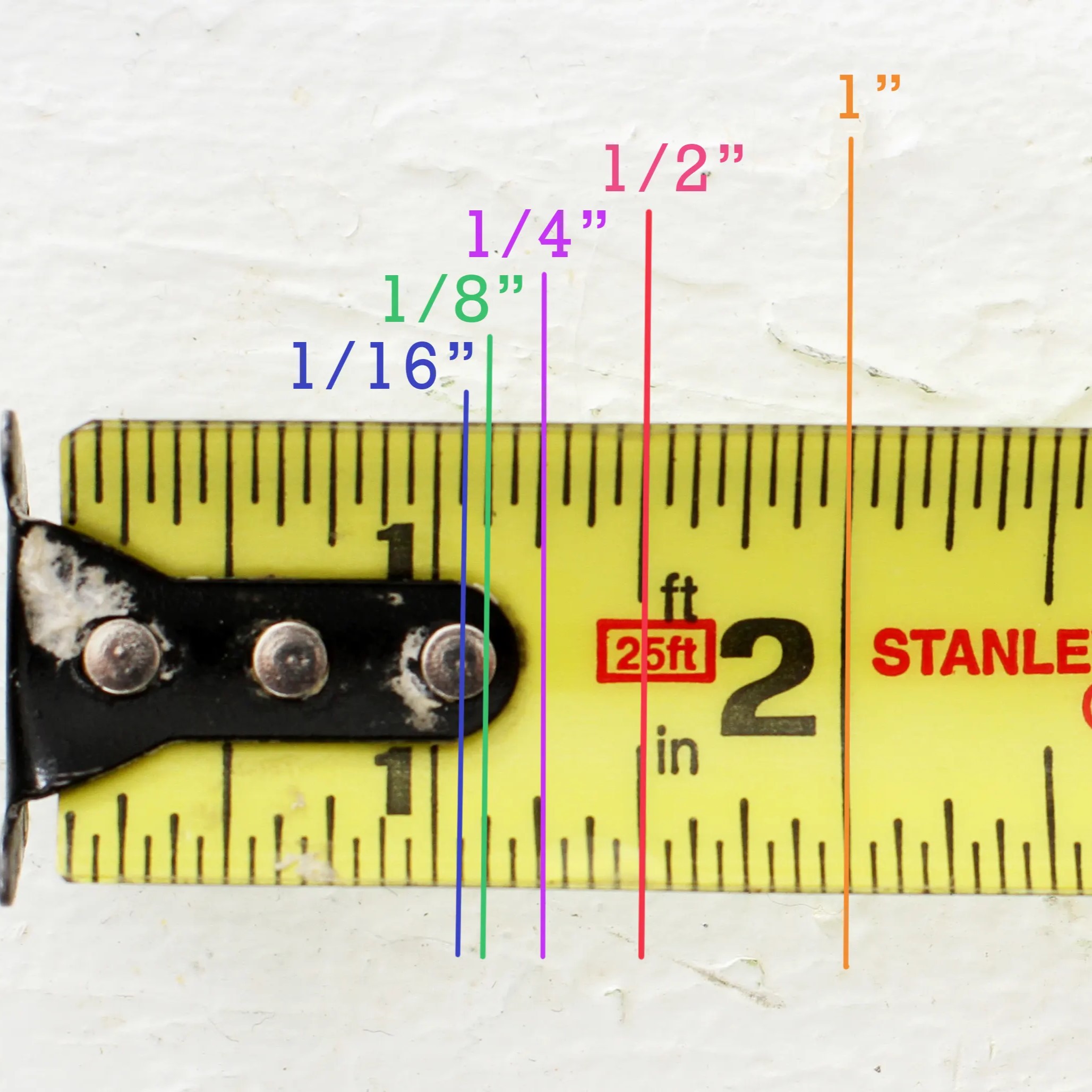

Firstly, understanding how to convert fractional measurements involving 5/8 inches can be incredibly useful. For example, breaking down 5/8 inches into smaller units, such as eighths or sixteenths of an inch, can provide greater precision in measurements. This is especially important in detailed woodworking or fine tailoring, where slight deviations can significantly impact the final product.

To convert 5/8 inches into sixthteenths, recognize that 5/8 inches equals 10/16 inches. This conversion simplifies complex measurements and makes it easier to work with various tools and materials that may require different units of measurement.

Combining with Metric Measurements

Additionally, combining the 5/8-inch measurement with metric units can enhance versatility, particularly in projects that require both imperial and metric precision. Understanding the relationship between 5/8 inches and its metric equivalent (approximately 15.875 millimeters) allows for seamless integration of measurements, especially in international or hybrid projects.

This dual-unit proficiency ensures that you can navigate between different measurement systems without compromising accuracy, catering to a broader range of projects and specifications.

Utilizing Digital Tools for Enhanced Accuracy

Moreover, leveraging digital measurement tools in conjunction with the 5/8 on a tape measure can significantly improve accuracy and efficiency. Digital tape measures and laser distance meters provide precise readings that can be easily converted and recorded. These tools often come with features like memory storage, unit conversion, and digital displays, which complement traditional tape measure techniques.

By integrating digital tools, you can enhance the precision of your 5/8-inch measurements and streamline the measurement process, particularly in large-scale or complex projects.

Incorporating the 5/8-inch Mark in Layouts and Templates

Furthermore, incorporating the 5/8-inch mark into layouts and templates can facilitate consistent and accurate construction and crafting processes. Creating reusable templates that highlight the 5/8-inch measurement ensures that repetitive tasks are performed with uniform precision. This is particularly useful in mass production settings or when creating multiple identical pieces.

The Role of 5/8 on a Measure Tape in Professional Settings

The Role of 5/8 on a Measure Tape in Professional Settings

In professional settings, the 5/8 on a tape measure is more than just a measurement mark; it represents a standard of precision and reliability that professionals rely on daily. Understanding its role and applications can significantly impact the quality and efficiency of professional work.

Meeting Industry Standards

Firstly, in many industries, the 5/8-inch measurement aligns with established standards and specifications. For example, in the construction industry, studs are commonly spaced at intervals that correlate with the 5/8-inch mark, ensuring that structures are built to code and maintain structural integrity. Adhering to these standards is essential for compliance, safety, and the overall success of projects.

Facilitating Communication and Collaboration

Moreover, using the 5/8-inch measurement fosters effective communication and collaboration among professionals. When team members are familiar with and consistently use this standard measurement, it simplifies the planning and execution of tasks. Clear and common measurement references reduce misunderstandings and ensure that everyone is on the same page, leading to smoother project workflows.

Frequently Asked Questions

Frequently Asked Questions

To further assist you in mastering the 5/8 on a tape measure, here are answers to some commonly asked questions that can enhance your understanding and application of this critical measurement.

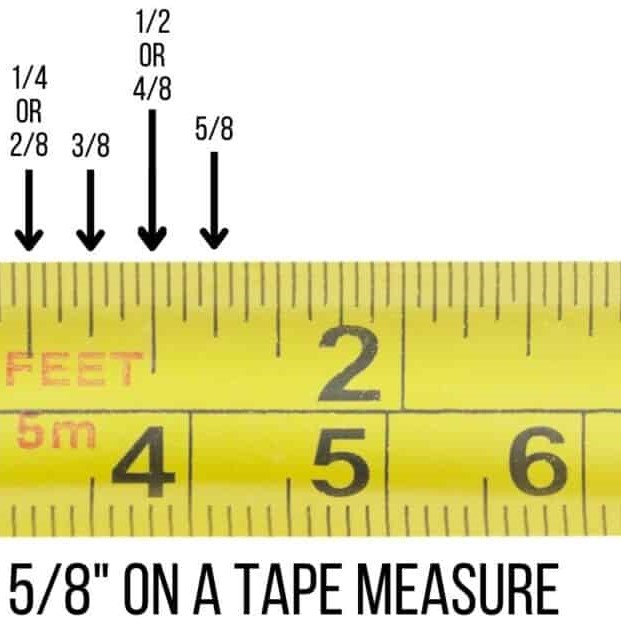

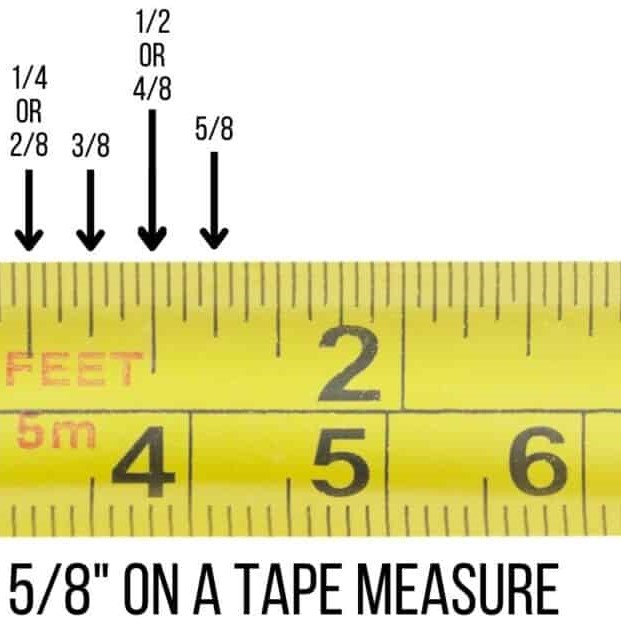

What is the significance of the 5/8-inch mark on a tape measure?

The 5/8-inch mark on a tape measure is significant because it represents a standard measurement commonly used in various industries, including woodworking, construction, and tailoring. It serves as a crucial reference point for precise measurements, ensuring consistency and accuracy in projects.

How do I accurately measure 5/8 inches?

To accurately measure 5/8 inches, first, ensure your tape measure is straight and taut against the object you’re measuring. Locate the 5/8-inch mark by identifying the smaller lines between the half-inch and one-inch markers. For added precision, use a magnifying glass or a measuring jig to clearly see the mark. Double-check the measurement by measuring it again to confirm accuracy.

How can I avoid mistakes when using the 5/8-inch mark?

To avoid mistakes when using the 5/8-inch mark, always ensure your tape measure is in good condition and properly calibrated. Use consistent and straight measurement techniques, double-check measurements, and utilize marking or notching for clarity. Additionally, practice regularly to become more familiar with reading and using the 5/8-inch measurement accurately.