Tape Measure Lines: Your Guide for Accurate Measurements

In the realm of construction, tailoring, and DIY projects, the importance of accurate measurements cannot be overstated. Central to achieving precision is understanding the intricacies of tape measure lines. These lines, etched or printed on the tape, serve as essential guides for achieving exact measurements. This comprehensive guide delves into the various aspects of tape measure lines, exploring their types, significance, and how to effectively utilize them to enhance your projects’ accuracy and efficiency.

The Evolution of Measurement Lines

The Evolution of Measurement Lines

Tape measures have been indispensable tools for centuries, evolving from simple rulers to the sophisticated devices we use today. Initially, tape measures featured basic markings, but the introduction of detailed tape measure lines revolutionized their functionality. These lines allow for more precise measurements, catering to the diverse needs of professionals and hobbyists alike.

Historical Development

The concept of measuring lengths dates back to ancient civilizations, where rudimentary measuring tools were used for building and crafting. However, the modern tape measure, complete with detailed lines, emerged in the 19th century. Early tape measures were made of cloth or metal strips with simple markings. Over time, advancements in metallurgy and printing techniques enabled the creation of more accurate and durable tape measures with finely detailed lines.

Technological Advancements

With the advent of digital technology, tape measures have integrated innovative features while retaining the essential tape measure lines. Today, we see tape measures with laser guides, digital displays, and even Bluetooth connectivity, enhancing their usability without compromising the precision provided by their line markings. These technological enhancements ensure that tape measure lines remain relevant and continue to serve as the cornerstone of accurate measurement.

Types of Measurement Lines

Understanding the different types of tape measure lines is crucial for selecting the right tape measure for your specific needs. Tape measures come in various formats, each designed to cater to different measurement systems and applications.

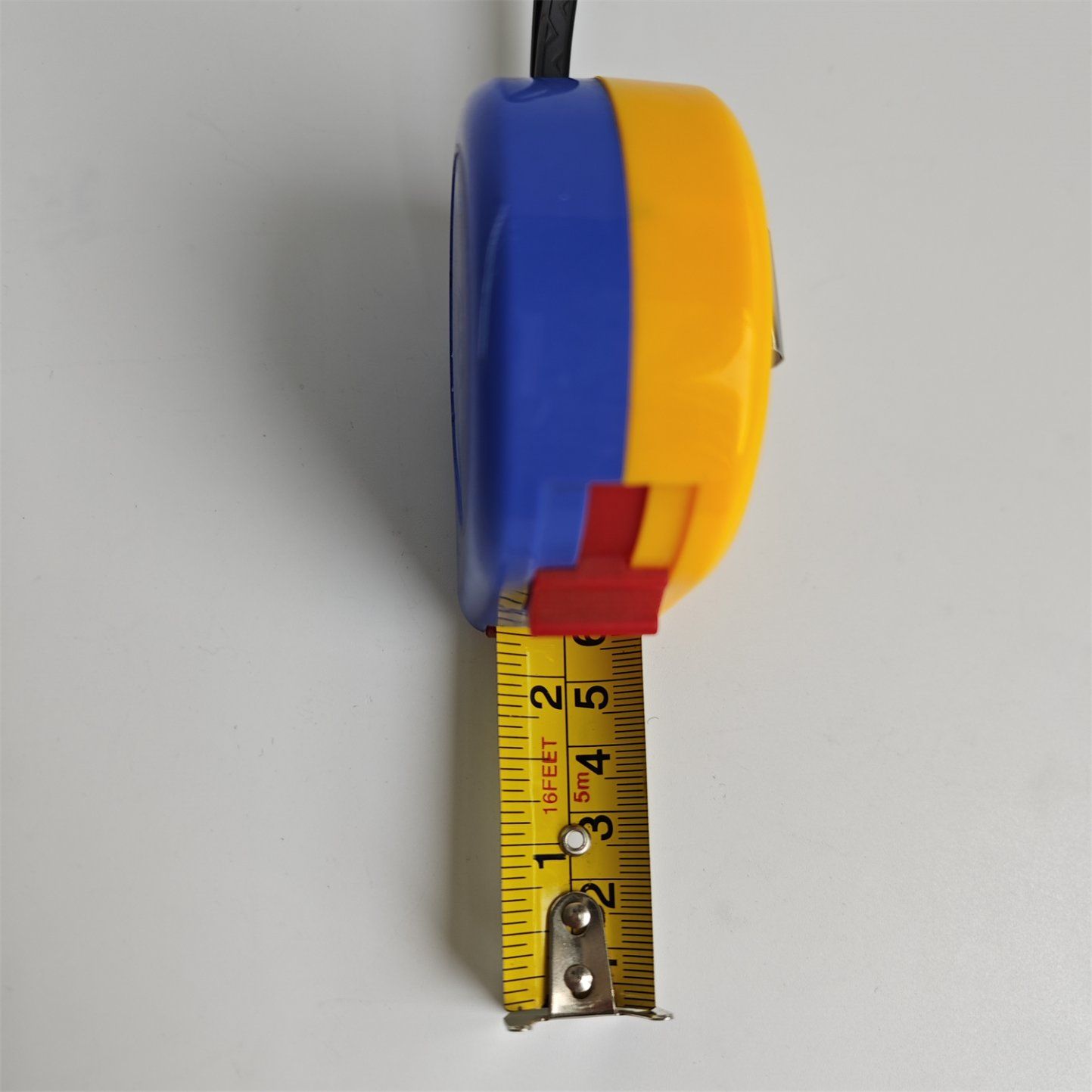

Imperial vs. Metric Tape Measure Lines

Tape measures are typically marked with either the imperial or metric system. Imperial tape measures use inches and feet, featuring lines at each inch with smaller marks indicating fractions such as halves, quarters, and eighths. Conversely, metric tape measures use centimeters and millimeters, with lines spaced at each centimeter and finer markings for millimeters. Choosing between imperial and metric lines depends largely on regional preferences and the standards of your specific industry.

Stud Marks and Construction Lines

In construction, tape measures often include stud marks, which indicate the positions of wall studs, typically spaced 16 or 24 inches apart. These tape measure lines help builders quickly locate studs without the need for additional tools. Construction lines may also include markings for joist spacing, making it easier to layout and frame structures accurately.

Specialized Tape Measure Lines

Some tape measures feature specialized lines tailored to specific tasks. For instance, architectural tape measures might include scale markings for drawing plans, while upholstery tape measures may have flexible, double-sided markings to accommodate fabric measurements. These specialized tape measure lines enhance the tool’s versatility, making it easier to switch between different project requirements.

The Importance of Accurate Measurement Lines

The Importance of Accurate Measurement Lines

Accurate tape measure lines are fundamental to ensuring precision in any project. Whether you’re building a house, tailoring clothing, or undertaking a DIY project, the reliability of your measurements directly impacts the quality of your work.

Enhancing Precision in Construction

In construction, precise measurements are critical for ensuring structural integrity and alignment. Misaligned studs or inaccurately measured joists can lead to significant issues, compromising the building’s stability and safety. Detailed tape measure lines provide builders with the accuracy needed to avoid costly errors and ensure that every component fits perfectly.

Ensuring Fit in Tailoring and Fashion

For tailors and fashion designers, accurate measurements are essential for creating garments that fit perfectly. Tape measure lines marked with fine increments allow for precise tailoring, ensuring that each piece of clothing matches the client’s dimensions exactly. This precision enhances the overall quality and comfort of the finished product, leading to greater customer satisfaction.

Facilitating DIY Projects

DIY enthusiasts rely on accurate measurements to execute projects successfully. From building furniture to home renovations, precise tape measure lines ensure that cuts and assemblies fit together seamlessly. This accuracy not only improves the aesthetic appeal of DIY projects but also their functionality and durability.

How to Read Measurement Lines Effectively

Mastering the ability to read tape measure lines accurately is essential for maximizing the tool’s potential. Properly interpreting the markings ensures that you take precise measurements, reducing the likelihood of errors.

Understanding Inch Markings

On imperial tape measures, each inch is typically marked with a large line, making it easy to identify. Between each inch, there are smaller lines indicating fractions of an inch. For example, lines between the 1-inch and 2-inch marks may denote halves, quarters, eighths, and sixteenths of an inch. Learning to quickly identify these fractions allows for more detailed and accurate measurements.

Mastering Centimeter and Millimeter Scales

Metric tape measures display measurements in centimeters and millimeters. Each centimeter is marked with a bold line, while smaller, more detailed lines represent millimeters. Using a metric tape measure requires familiarity with these increments to ensure accurate measurements, especially for projects that demand high precision.

Utilizing Stud Marks and Specialized Lines

Certain tape measures include additional markings such as stud marks or specialized lines for specific applications. Understanding and utilizing these additional tape measure lines can significantly enhance efficiency. For example, using stud marks can speed up the process of locating wall studs in construction, while specialized lines can aid in tasks like drawing architectural plans or measuring fabric.

Choosing the Right Tape Measure with Appropriate Lines

Choosing the Right Tape Measure with Appropriate Lines

Selecting the right tape measure involves considering the type of tape measure lines that best suit your needs. Different projects require different levels of precision and types of markings, so understanding your specific requirements is crucial.

Assessing Your Measurement Needs

Start by assessing the types of projects you typically undertake. If you work primarily with imperial measurements, an inch-based tape measure with detailed fraction markings will be essential. Conversely, if your work requires metric measurements, a centimeter and millimeter-marked tape measure will be more appropriate. Additionally, consider whether you need specialized lines, such as stud marks or scale markings, to enhance your workflow.

Evaluating Tape Measure Quality

The quality of the tape measure, including the clarity and durability of its lines, plays a significant role in its effectiveness. High-quality tape measures feature clearly printed or etched lines that resist fading and wear over time. A well-made tape measure ensures that tape measure lines remain legible, even after extensive use, maintaining accuracy and reliability.

Considering Length and Portability

Tape measures come in various lengths, typically ranging from 12 feet to 100 feet. The length you choose depends on the scope of your projects. For general use and portability, a 25-foot tape measure is often sufficient. However, for larger projects, such as building structures or landscaping, longer tape measures with robust tape measure lines may be necessary. Additionally, consider the tape measure’s design, such as retractable mechanisms and belt clips, to ensure ease of use and portability.

Innovations Enhancing Measurement Lines

Modern advancements have introduced several innovations that enhance the functionality and readability of tape measure lines. These features improve the user experience, making tape measures more intuitive and efficient.

Laser-Engraved Lines

Laser engraving technology has improved the precision and durability of tape measure lines. Laser-engraved lines are sharper and more resistant to fading, ensuring long-term readability. This innovation is particularly beneficial for professionals who require persistent and accurate measurements throughout extensive projects.

Color-Coded Markings

Some tape measures feature color-coded lines to differentiate between various measurement scales or specialized markings. Color coding can make it easier to quickly identify specific measurements, such as stud marks or scale increments, enhancing efficiency and reducing the time spent searching for the right markings.

Flexible and Durable Materials

Advancements in materials have led to the creation of more flexible and durable tape measures. Materials like fiberglass and reinforced steel not only extend the tape measure’s lifespan but also ensure that tape measure lines remain intact and readable, even under heavy use or in harsh environments. These durable materials are ideal for professionals who require reliable tools that can withstand rigorous conditions.

Maintenance and Care

Maintenance and Care

Proper maintenance and care are essential to preserve the integrity of tape measure lines and ensure the longevity of your tape measure. Regular upkeep prevents wear and tear, maintaining the accuracy and functionality of the tool.

Cleaning Your Tape Measure

Regular cleaning helps keep the tape measure free from dirt, debris, and rust, which can obscure tape measure lines and hinder accurate measurements. Wipe the tape measure with a damp cloth after each use, especially if it has been exposed to moisture. For stubborn dirt or grime, use a mild soap solution and a soft brush to gently scrub the tape measure. Avoid using harsh chemicals that can damage the markings or the tape’s material.

Storing Properly

Proper storage protects the tape measure from damage and preserves the clarity of tape measure lines. Store the tape measure in a dry, cool place, away from direct sunlight and extreme temperatures. Using a protective casing or pouch can prevent scratches and other physical damage that may obscure the lines. Additionally, avoid tangling the tape by ensuring it retracts fully and hooks securely when not in use.

Regular Inspection

Frequent inspection of the tape measure ensures that tape measure lines remain intact and readable. Check for signs of wear, such as fading lines, cracks, or loose markings, and address any issues promptly. If the tape measure becomes damaged or the lines are no longer clear, consider replacing it to maintain measurement accuracy.

Common Mistakes and Tips

Avoiding common mistakes and adopting best practices ensures that you make the most of your tape measure’s tape measure lines. These tips can enhance your measurement accuracy and overall efficiency.

Misreading the Zero Point

One common mistake is misreading the zero point of the tape measure. Ensure that the tape starts precisely at zero and that you are measuring from the correct starting point. Misalignment can lead to inaccurate measurements, affecting the quality of your project.

Not Holding the Tape Flat

Holding the tape measure flat against the surface being measured is crucial for accuracy. Allow the tape measure lines to lie smoothly without bending or twisting, as this can distort the measurements. Use a steady hand to keep the tape level and taut, ensuring consistent and precise readings.

Ignoring the Tape’s Flexibility

Taping measures can curve or bend, especially with longer lengths. Ignoring the tape’s flexibility can result in inaccurate measurements. For precise readings, ensure that the tape is straight and fully extended without sagging. Using a helper to hold the tape can improve accuracy for larger measurements.

Overlooking Markings and Increments

Pay close attention to the smaller increments on the tape measure’s lines. Missing these fine details can lead to rounding errors and inaccurate measurements. Take the time to understand the full scale of tape measure line, including fractions and millimeters, to achieve the highest level of precision in your measurements.

Using Damaged Tape Measures

Using a damaged tape measure with faded or unclear tape measure line can compromise measurement accuracy. Regularly inspect the tape measure and replace it if the lines are no longer easily readable or if the tape itself is worn out. A clear and undamaged tape is essential for reliable measurements.

Future Trends in Measurement Lines

The future of tape measure lines promises continued innovation, bridging traditional measurement techniques with modern technology. Emerging trends are set to enhance the functionality and usability of tape measures, making them even more indispensable tools.

Integration with Digital Technology

One of the most significant trends is the integration of digital technology with tape measure lines. Digital displays can complement physical markings, providing additional information such as digital measurements and calculation capabilities. This hybrid approach enhances precision and offers users versatile measurement options.

Smart Tape Measures

Smart tape measures equipped with sensors and connectivity features are becoming increasingly popular. These devices can sync with smartphones and other digital devices, recording measurements and transferring data seamlessly. This connectivity allows for more efficient data management and integration with digital planning tools, streamlining the measurement process for professionals.

Enhanced Durability and Flexibility

Future tape measures will likely incorporate even more durable and flexible materials, ensuring that tape measure lines remain clear and accurate over extended use. Advances in materials science will lead to tape measures that can withstand harsher conditions while maintaining their functionality and readability.

Eco-Friendly Designs

Sustainability is becoming a key consideration in tool design, and tape measures are no exception. Future innovations may include eco-friendly materials and manufacturing processes, ensuring that tape measure lines are produced and maintained in a manner that minimizes environmental impact. This trend aligns with the growing demand for sustainable and responsible tool manufacturing.

Conclusion

Conclusion

In conclusion, tape measure lines are fundamental to achieving precision and accuracy in a wide range of applications, from construction and tailoring to DIY projects and beyond. Understanding the different types of lines, their significance, and how to effectively utilize them can significantly enhance the quality of your work. As technology continues to evolve, tape measure lines will remain a crucial component of these indispensable tools, bridging the gap between traditional craftsmanship and modern innovation.

By selecting the right tape measure, maintaining its lines, and mastering the art of measurement, you can ensure that your projects are executed with the highest level of accuracy and efficiency. Whether you are a professional tradesperson or a passionate DIY enthusiast, the tape measure line you rely on daily play a pivotal role in bringing your visions to life with precision and confidence.