Installing Power Steering Pulley: No Tool? No Problem!

Overview of Power Steering Pulley Installation

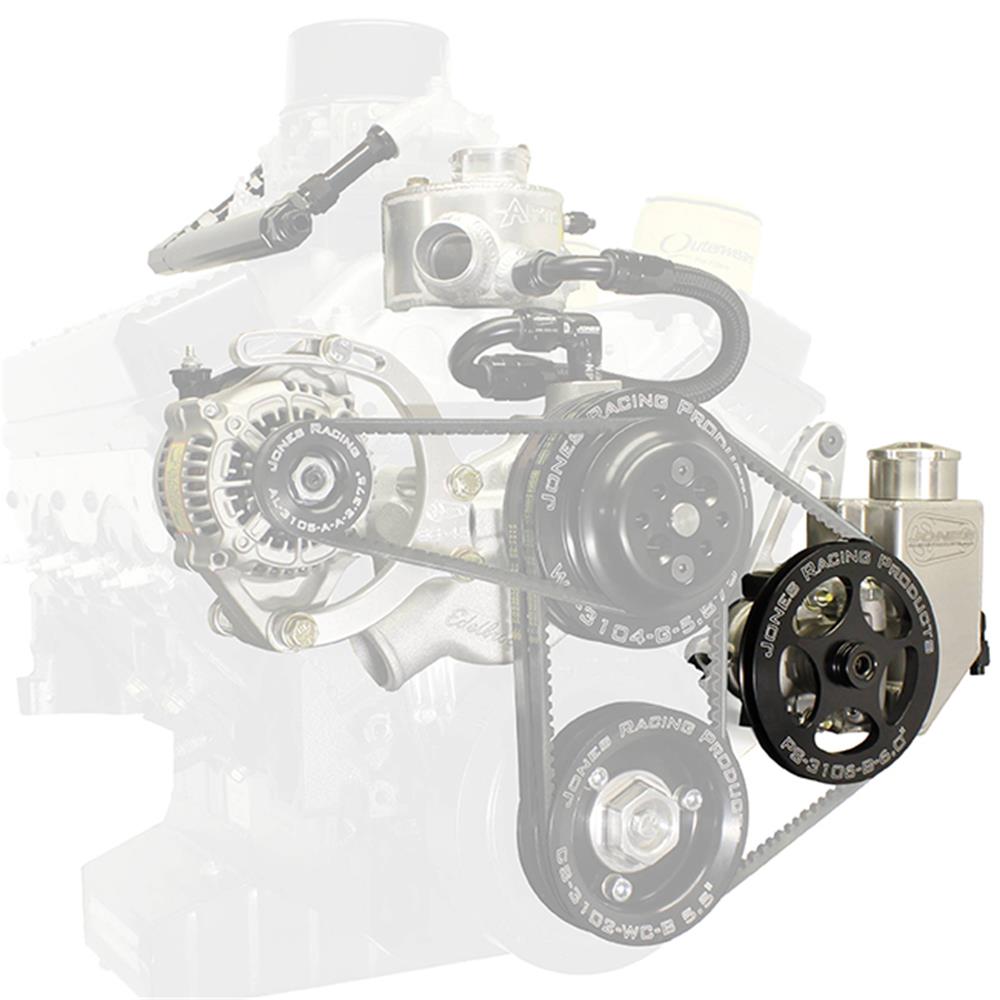

Installing a power steering pulley can seem daunting without the right tool. Yet, with some ingenuity, it’s achievable. The power steering pulley is vital for your vehicle’s steering system. It helps the power steering pump exert the required pressure. How to install power steering pulley without tool? This aids in turning the vehicle’s wheels with less effort. Over time, the pulley may wear out or become damaged. This calls for removal and installation of a new one.

To install a power steering pulley without a tool, you need to understand its function first. A pulley system uses belts to transfer rotational motion from the engine. This drives the power steering pump. When the pulley is not functioning well, steering your vehicle becomes harder. Installing a new pulley helps to restore the functionality of your power steering system.

Another key point is that this task involves precision and safety precautions. Without proper installation, you might face further issues down the road. Therefore, although specialized tools are not at hand, it’s crucial to follow meticulous steps. It ensures a secure and effective installation. This can save time and avoid extra expense or damage to other parts.

Throughout this blog, we will discuss how to install power steering pulley without tool. The focus will be on practical steps, precautions, and how to make do without commercial pulley installation tools. Remember, safety always comes first. Wear protective gear, and ensure the vehicle is stable before proceeding.

Preparing for the Installation: Tools and Safety

Before starting the installation, safety cannot be overstated. You must have a secure work area. Make sure the car is parked on a flat surface and that the parking brake is set. Disconnect the car’s battery to prevent any electrical accidents.

Next, gather the necessary items for the installation. While you don’t have a specific pulley tool, collect alternatives. You will need a set of screwdrivers, a hammer, a pair of gloves, and safety goggles. Depending on your approach, you might also need a socket set and a long bolt that matches the thread of the pulley hole.

Make sure the tools you choose are strong and right for the job. They should fit the parts you will work on precisely. Wear gloves and goggles to protect your hands and eyes from any flying debris or spills. Read all instructions carefully before beginning. Know the steps to how to install power steering pulley without tool.

Lastly, remember to keep patience. A manual installation might take more time than using specialized tools. But with careful execution, it is achievable. Ensure all prepared tools are close at hand. This makes for a smoother installation process. Your focus is to make the installation safe and effective without the pulley tool.

Step-by-Step Manual Installation Process

To install a power steering pulley without specialized tools, follow these steps carefully:

- Verify the Pulley and Bolt Thread Match: Make sure the long bolt you have matches the power steering pulley’s thread. This is crucial for a safe and proper fit.

- Position the Pulley: Align the new pulley with the power steering pump shaft. The grooves on the pulley should face the belt.

- Thread the Bolt: Carefully insert the long bolt into the pulley’s center hole. Screw it in by hand as far as it will go.

- Secure the Pulley: Using a socket that fits the bolt head, slowly tighten the bolt. This will draw the pulley onto the shaft.

- Apply Even Pressure: As you tighten the bolt, make sure the pulley slides on evenly. If it seems crooked, loosen it slightly and adjust before tightening again.

- Check for Alignment: Once it’s secure, check that the pulley is perfectly aligned with the other pulleys. Misalignment can cause belt wear or noise.

- Tighten to Specification: Ensure the pulley is tightened to the vehicle’s specifications. Over or under-tightening can cause issues later on.

- Verify Movement: Spin the pulley by hand to check for free movement and secure fit.

- Reassemble: Put any removed parts back in place. Reconnect the car’s battery. Start the engine to ensure that the pulley is working correctly. Listen for any unusual sounds.

Be patient and take your time with each step. If at any point, something seems off, do not force components together. Double-check your alignment and fittings. Installing a power steering pulley without a tool takes finesse, but with care, you can achieve a sound installation.

Tips and Tricks for Installing Without Specialized Tools

When installing a power steering pulley without a traditional tool, creativity is key. Here are some tips to help make the process easier:

- Use a Bolt and Nut Combination: Find a long bolt and a nut that match the power steering pulley’s thread. This makeshift tool can pull the pulley onto the shaft.

- Lubricate Threads: Apply some lubricant to the threads of the bolt. This reduces friction and makes it easier to tighten.

- Ensure Stable Support: Brace the power steering pump shaft so it does not move when applying pressure. Use a piece of wood or another firm object.

- Even Force Application: Tighten the bolt in stages. Rotate the pulley slightly after each tightening to ensure even movement.

- Inspect Regularly: Check your progress frequently. Make sure the pulley is not tilting or getting stuck.

- Avoid Hammering: Do not use a hammer directly on the pulley. This can cause damage. If tapping is needed, use a piece of wood between the hammer and the pulley.

- Stop If Unsure: If something feels wrong, stop immediately. Review the steps or consult a professional.

These tips can greatly aid in how to install power steering pulley without tool. Remember, take your time and stay focused on the task.

Troubleshooting Common Issues During Installation

When attempting to install a power steering pulley without a tool, you might face some hiccups. Here are common issues and how to handle them:

- Pulley Misalignment: If the pulley isn’t lining up with the other pulleys, it can lead to belt problems. Loosen the bolt, adjust the alignment, then tighten again.

- Bolt Won’t Thread: Sometimes, the bolt may not thread easily into the pulley. Check for cross-threading, and ensure you have the correct size. A touch of lubricant can help.

- Pulley Won’t Move: If the pulley won’t slide onto the shaft, check for obstructions. Ensure the bolt is the right length and apply steady pressure.

- Noise After Installation: Unusual noises might indicate a loose or tight pulley. Ensure it’s tightened to the manufacturer’s specification and aligned properly.

- Belt Slippage Post-Installation: This could be due to misalignment or a loose pulley. Double-check alignment and tighten as needed.

By anticipating these issues and knowing how to address them, you’ll be better equipped to install your power steering pulley without a tool. Keep calm, refer to these tips, and proceed with caution and confidence.

Maintenance After Installation: Ensuring Longevity

After installing the power steering pulley without a tool, maintenance is crucial for ensuring its longevity. Here are essential tips to help you maintain your newly installed pulley:

- Regular Inspections: Check the pulley and belt regularly for any signs of wear or damage. Early detection can prevent bigger problems.

- Listen for Noises: Be attentive to any unusual sounds. Squealing or grinding could indicate a misalignment or a loose pulley.

- Monitor Belt Tension: The belt tension should be adequate. Over time, belts can stretch. Adjust as necessary.

- Clean the Pulley: Keep the pulley free from dirt and debris. This can reduce wear and tear.

- Lubricate When Necessary: Apply lubricant to the pulley’s bearings if accessible. This helps in smooth operation.

- Avoid Overloading: Do not overstress the steering system by rugged driving. It increases wear on the pulley and belt.

- Check for Corrosion: Inspect the pulley for any signs of rust or corrosion. Address it promptly to avoid further damage.

Regular upkeep will extend the life of your power steering pulley and ensure optimal performance. Maintaining these components is less costly than replacing them due to neglect.

When to Consider Professional Installation

Although DIY methods can be effective, there are instances when you should consider professional installation. Here are some circumstances:

- Complexity Exceeds Comfort: If the installation process seems too complex or risky, it’s safer to seek a professional.

- Lack of Proper Tools: Sometimes, even alternative tools won’t suffice. Professionals have the right equipment.

- Repeated Issues: If you encounter consistent issues with power steering, professional expertise may be necessary.

- Time Constraints: When you don’t have enough time to invest in learning how to install power steering pulley without tool, a mechanic can be quicker.

- Warranty Concerns: DIY installations may void warranties. Confirm with your vehicle manufacturer beforehand.

Remember, there’s no shame in wanting the best for your vehicle. Professionals are trained to handle these situations efficiently and safely.

Alternatives to Manual Installation: DIY Tools and Hacks

When installing a power steering pulley without a tool, you need alternatives. Let’s explore DIY tools and hacks that can act as substitutes for professional tools. These alternatives might not only save the day but also can be easy on the wallet.

- Make Your Own Pulley Puller: You can create a pulley puller with common hardware store items. Get a long bolt, nuts, washers, and a metal rod. Make sure they fit your pulley’s specifications.

- Use a C-Clamp: A sturdy C-clamp can sometimes be used to press the pulley onto the shaft. Just be careful not to apply too much force.

- Socket Wrench Trick: Some have managed to use a socket wrench and sockets as a makeshift pulley installation tool.

- The Pipe Wrench Method: With caution, a pipe wrench can grip the pulley’s edge to help slide it into place. Again, be gentle to avoid damage.

- Modify Existing Tools: Look at your existing tools. You might be able to modify one to suit your needs. But do not compromise safety.

Every hack has its risks and it is crucial to be cautious. If you’re not confident, consider asking for help or consulting a professional. With a bit of creativity and these hacks, you can learn how to install power steering pulley without tool successfully.